Thermal insulation material combined type solar greenhouse

A technology of thermal insulation materials and solar greenhouses, applied in the field of solar greenhouses, can solve the problems of inconvenient transportation, large volume and weight of heat storage and thermal insulation materials, and affect the progress of construction, etc., and achieve the effects of short installation period, good thermal insulation effect and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

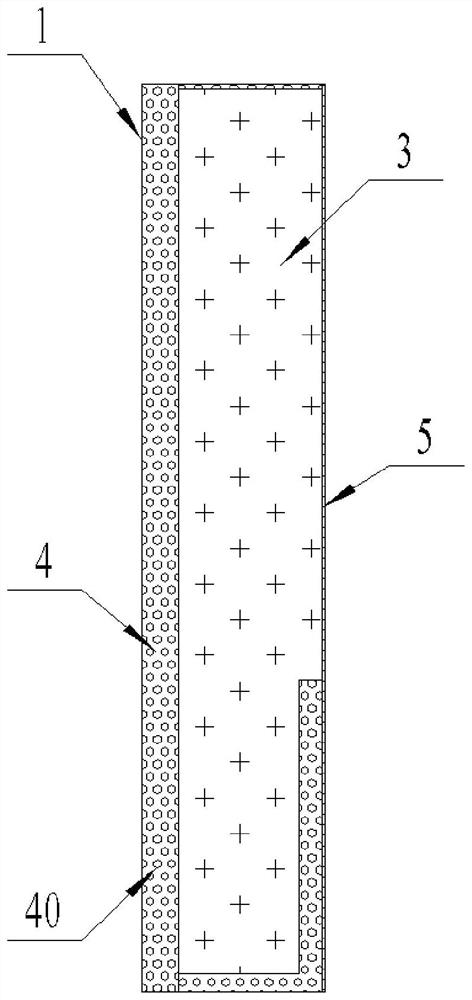

[0063] Insulation composite wallboard 4 is made of concrete mixture and polystyrene foam particles that introduce air during the mixing process, and then form a plurality of honeycomb air holes in the core layer to further reduce the product’s bulk density, and pass through the composite molding machine and aluminum mold. made. Among them, the volume ratio of concrete mixture to polystyrene foam particles is 1:3.

[0064] Concrete mixture is made by mixing Portland cement, fine aggregate, and additives. The mass ratio of Portland cement, fine aggregate, and additives is 30:50:4.

[0065] Specifically, fine aggregate is fine sand and fly ash; additives include defoamer and water reducer. Defoamers and water reducers are commonly used additives in construction.

Embodiment 2

[0067] Insulation composite wallboard 4 is made of concrete mixture and polystyrene foam particles that introduce air during the mixing process, and then form a plurality of honeycomb air holes in the core layer to further reduce the product’s bulk density, and pass through the composite molding machine and aluminum mold. made. Among them, the volume ratio of concrete mixture to polystyrene foam particles is 1:1.

[0068] Concrete mixture is made by mixing Portland cement, fine aggregate, and additives. The mass ratio of Portland cement, fine aggregate, and additives is 20:50:1.

[0069] Specifically, the fine aggregates are fine sand, fly ash, and slag; the additives include defoamers and water reducers.

Embodiment 3

[0071] Insulation composite wallboard 4 is made of concrete mixture and polystyrene foam particles that introduce air during the mixing process, and then form a plurality of honeycomb air holes in the core layer to further reduce the product’s bulk density, and pass through the composite molding machine and aluminum mold. made. Among them, the volume ratio of concrete mixture to polystyrene foam particles is 1:4.

[0072] Concrete mixture is made by mixing Portland cement, fine aggregate, and additives. The mass ratio of Portland cement, fine aggregate, and additives is 50:80:8.

[0073] Specifically, fine aggregate is fine sand and fly ash; additives include defoamer and water reducer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Heat transfer coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com