Preparation method of luminous zipper

A zipper and chain embryo technology, which is applied in the preparation of luminous zippers and zippers, can solve the problems of poor overall experience and partial luminescence of luminous zippers, and achieve the effects of reasonable process arrangement, safe use and moderate production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

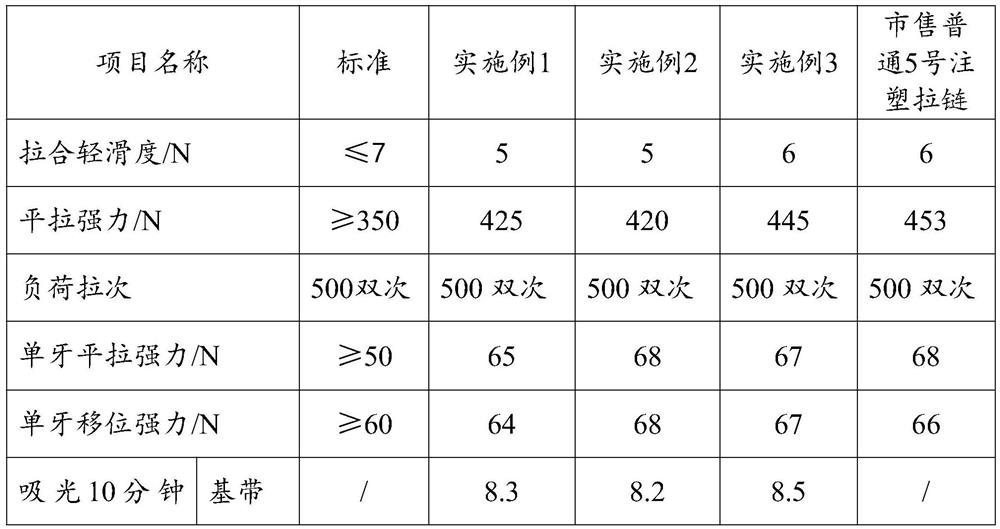

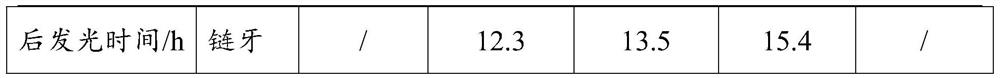

Embodiment 1

[0016] The yarn specification is 167dtex / 36f / 2 low-elastic medium mesh energy storage luminous polyester yarn is woven into a luminous zipper base belt through a warp and weft loom, the warp and weft ratio is 3:2, and the weaving density is 224×168. The obtained luminous zipper base belt has the function of energy storage and luminescence; after the luminous zipper base belt is washed, baked, cut, and edge-sealed, it is shaped and leveled by an electric ironing machine; The luminous zipper base belt is combined and injected into a zipper chain blank, in which the energy storage luminous injection plastic particles are injection molded particles made of 100 parts of injection molding POM material mixed with 0.5 parts of energy storage luminescent powder and 0.6 parts of antioxidant. The processing parameters of the injection molding machine are: heating The temperature is 160°C, the injection speed is 1.6s, the mold holding time is 1.5s, and the cooling time is 1.5s; after finis...

Embodiment 2

[0018] The yarn specification is 167dtex / 36f / 2 low-elastic medium mesh energy storage luminous polyester yarn is woven into a luminous zipper base belt through a warp and weft loom, the warp and weft ratio is 3:2, and the weaving density is 224×168. The obtained luminous zipper base belt has the function of energy storage and luminescence; after the luminous zipper base belt is washed, baked, cut, and edge-sealed, it is shaped and leveled by an electric ironing machine; The luminous zipper base belt is combined and injected into a zipper chain embryo, in which the energy storage luminous injection plastic particles are injection molded particles made of 100 parts of injection molding POM material mixed with 1 part of energy storage luminescent powder and 0.6 parts of antioxidant. The processing parameters of the injection molding machine are: heating The temperature is 180°C, the injection speed is 1.4s, the mold holding time is 2s, and the cooling time is 1.8s; the light-emitt...

Embodiment 3

[0020] The yarn specification is 167dtex / 36f / 2 low-elastic medium mesh energy storage luminous polyester yarn is woven into a luminous zipper base belt through a warp and weft loom, the warp and weft ratio is 3:2, and the weaving density is 224×168. The obtained luminous zipper base belt has the function of energy storage and luminescence; after the luminous zipper base belt is washed, baked, cut, and edge-sealed, it is shaped and leveled by an electric ironing machine; The luminous zipper base belt is combined and injected into a zipper chain blank. The energy storage luminous injection plastic particles are injection molded particles made of 100 parts of injection molding POM material mixed with 2 parts of energy storage luminous powder and 0.6 parts of antioxidant. The processing parameters of the injection molding machine are: heating The temperature is 170°C, the injection speed is 1.7s, the mold holding time is 1.8s, and the cooling time is 2s; after finishing processes s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com