Stacking mechanism for PCB automatic sorting machine

An automatic sorting and sorting machine technology, applied in the field of stacking mechanism, can solve the problems of wasting time and reducing the efficiency of sorting, and achieve the effects of speeding up efficiency, reducing manual accumulation and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

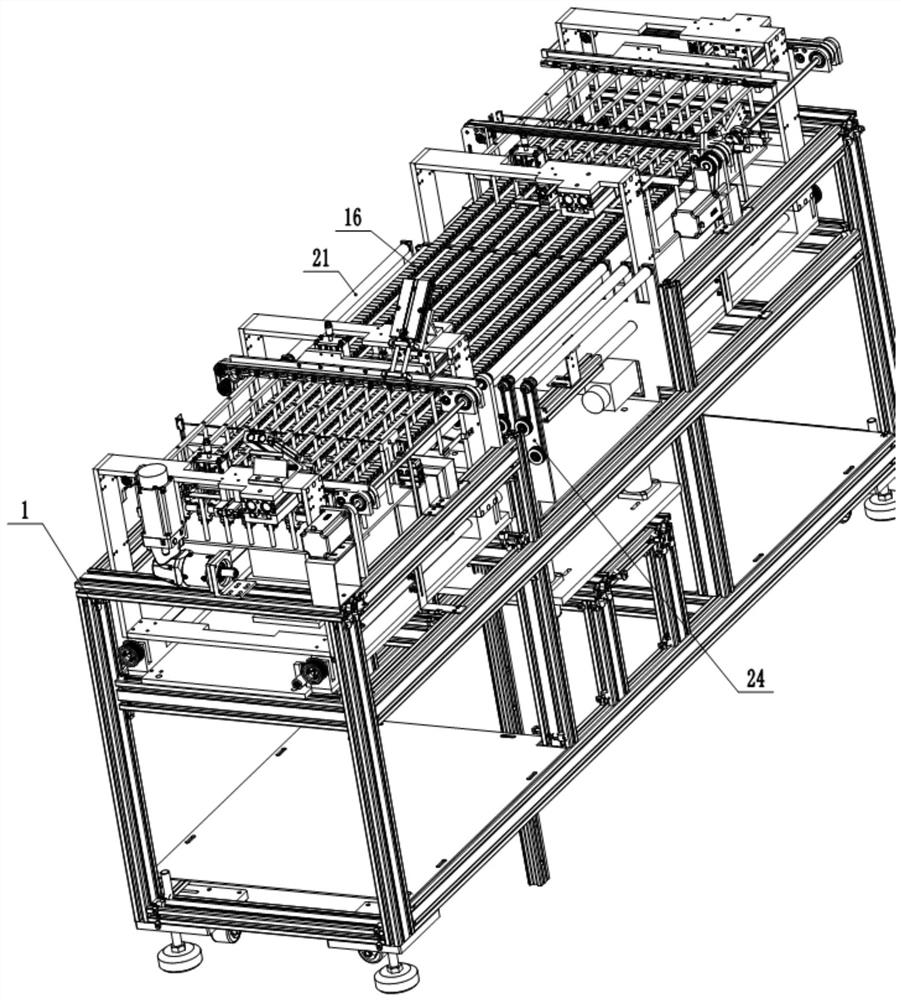

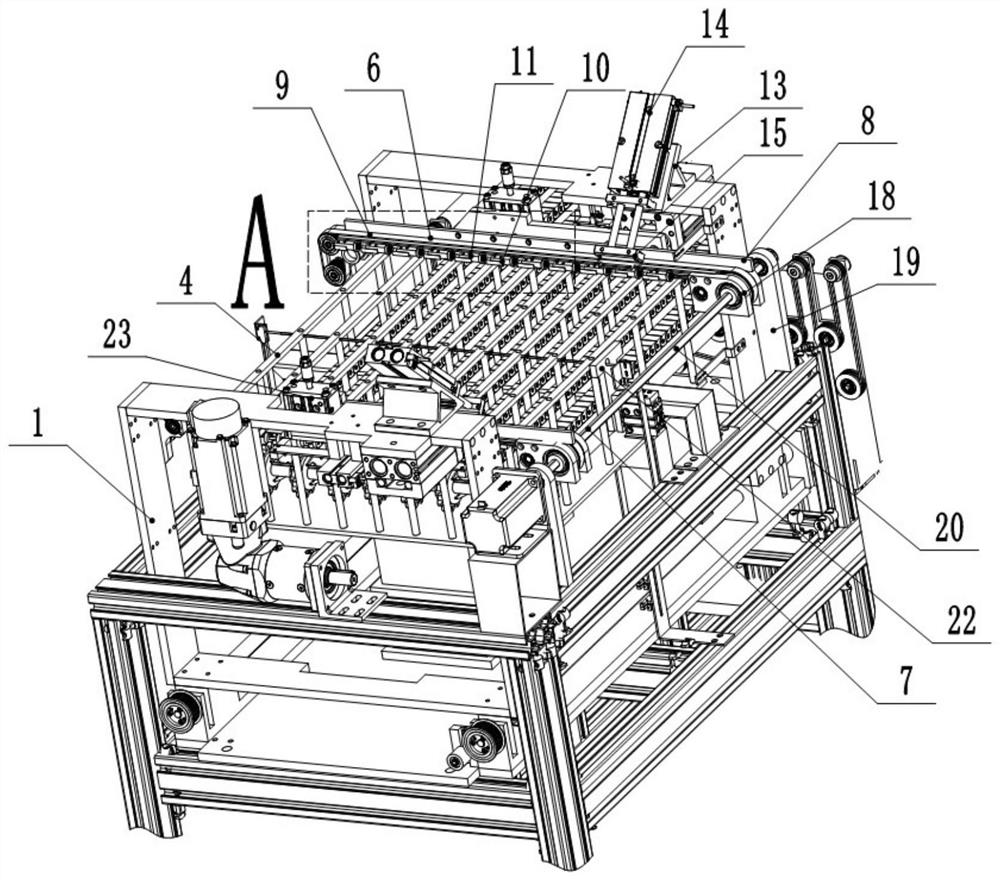

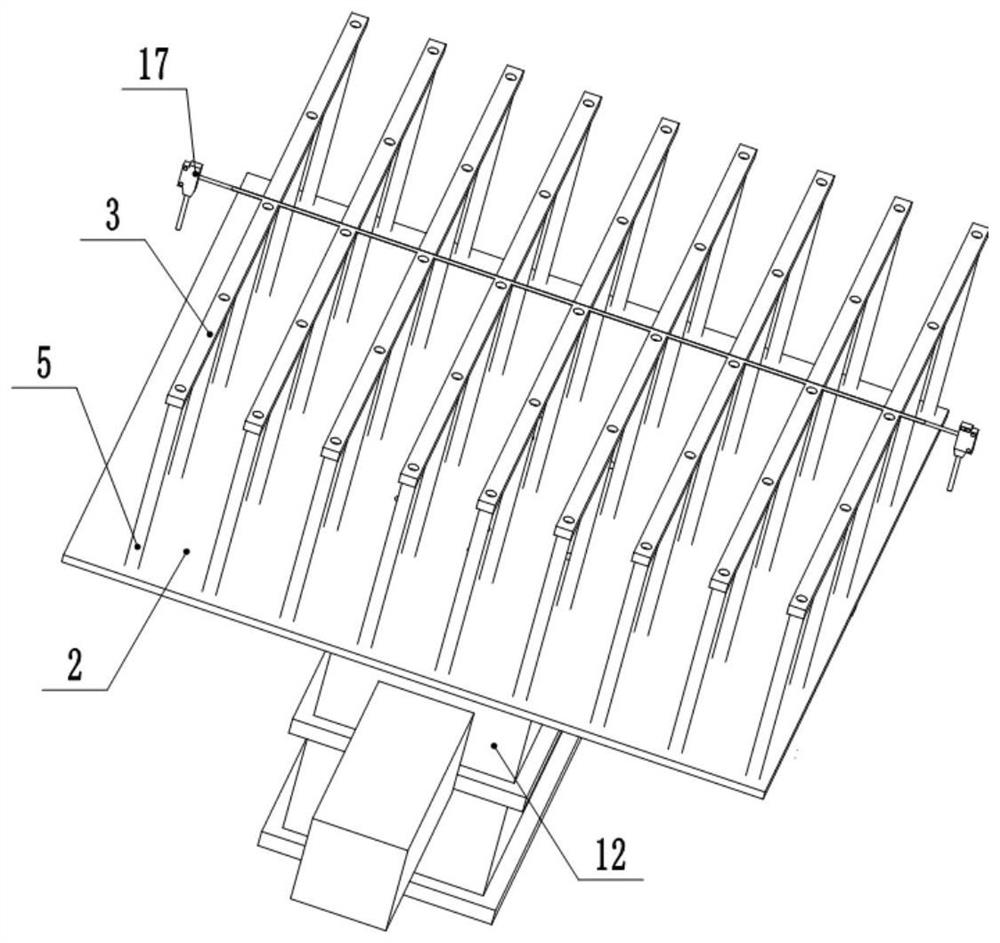

[0022] The following is further described in detail through specific implementation methods:

[0023] The reference signs in the drawings of the description include: sorting rack 1, connecting plate 2, cross bar 3, receiving assembly 4, vertical bar 5, transport part 6, mobile unit 7, transport frame 8, conveyor belt 9, support plate 10, Roller 11, first driving member 12, support block 13, fifth driving member 14, pressing block 15, conveying part 16, infrared sensor 17, connecting block 18, fixed frame 19, spline shaft 20, roller 21, first Clapper 22, the third driver 23.

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com