High-speed paper cutting machine and control system thereof

A control system and paper cutter technology, applied in metal processing and other directions, can solve the problems of wasting manpower, sticking, delaying cutting progress, etc., and achieve the effect of improving convenience and maintaining cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

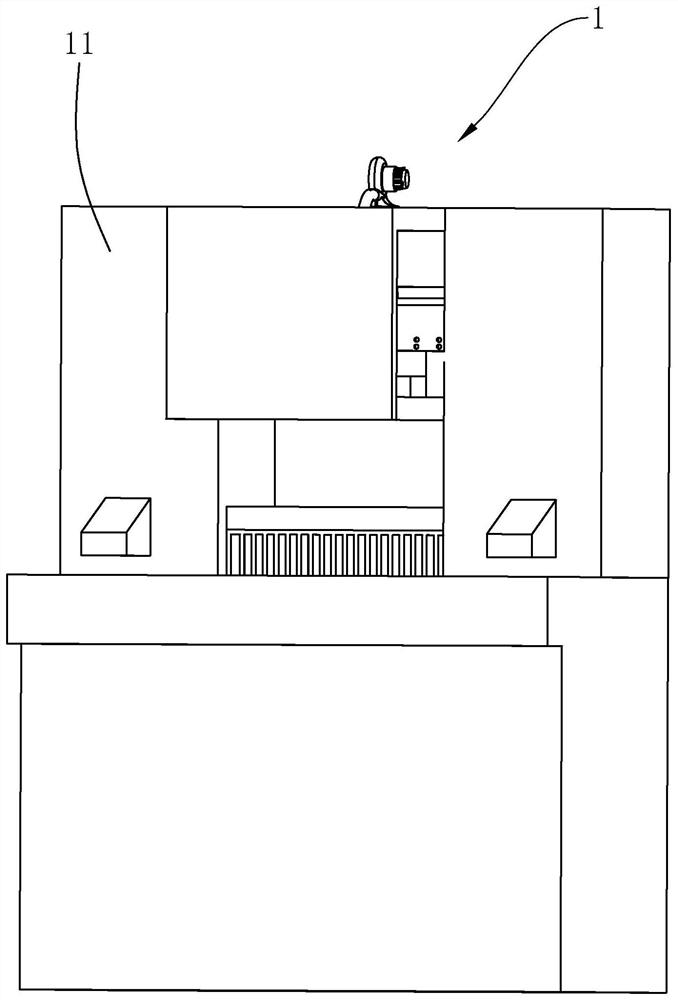

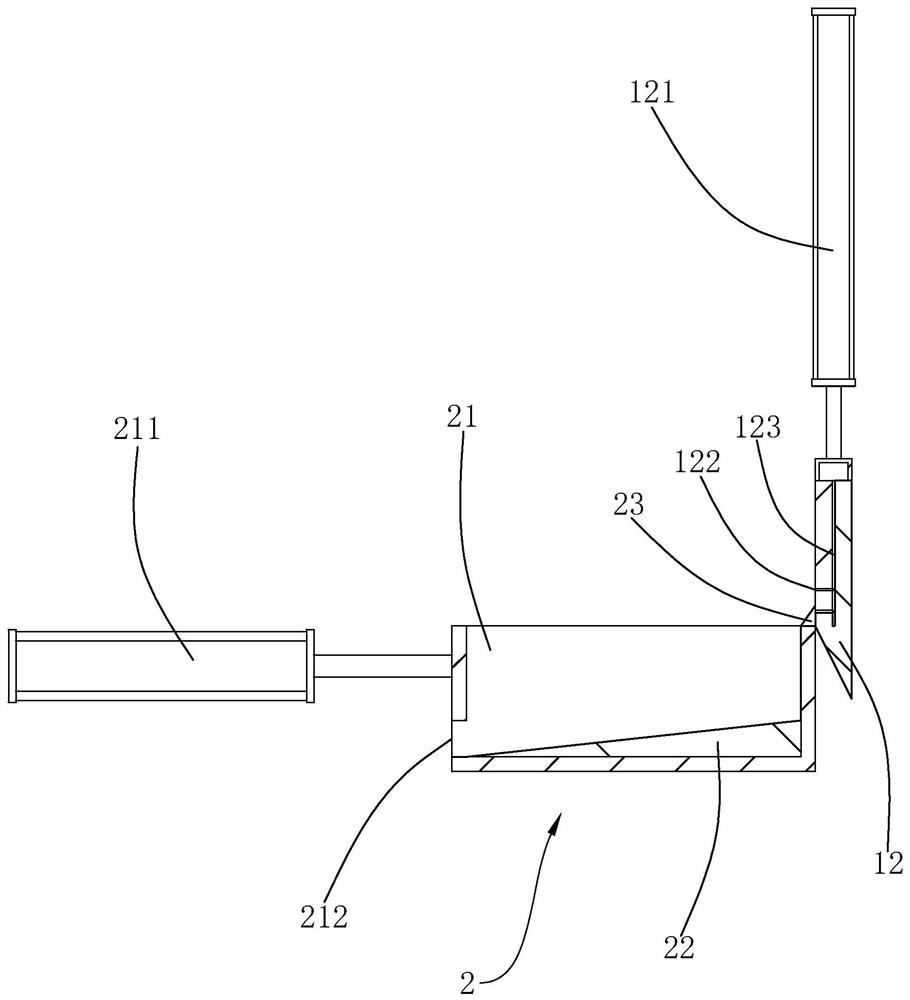

[0049] refer to figure 1 , figure 2 , is a high-speed paper cutter disclosed in the present invention, comprising a paper cutter body 1, the paper cutter body 1 includes a body 11, a cutting knife 12 mounted on the body 11, and a cutter for driving the cutting knife 12 to move. cutting agencies. Cutting mechanism comprises lift cylinder 121, and the base of lift cylinder 121 is fixedly connected with body 11, and the piston rod of lift cylinder 121 places the below of lift cylinder 121 base, and the piston rod of lift cylinder 121 stretches along vertical direction; Lift cylinder 121 The bottom end of the piston rod is fixedly connected with the top surface of the cutter 12, and when the piston rod of the lift cylinder 121 stretches out, the cutter 12 can cut the corners of the paper.

[0050] refer to figure 2 The cutting knife 12 is provided with a plurality of suction holes 122 on the side close to the corner of the paper, and the plurality of suction holes 122 are arr...

Embodiment 2

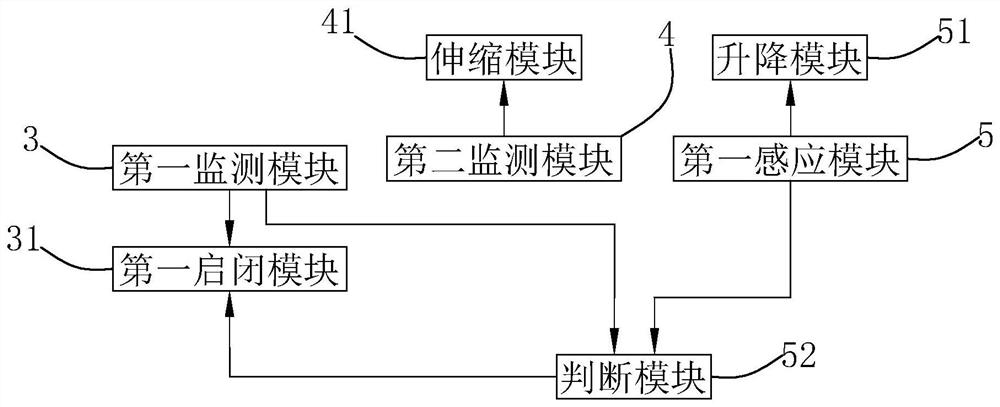

[0057] refer to image 3 , on the basis of embodiment 1, the control system of a kind of high-speed paper cutter disclosed by the present invention comprises:

[0058] The lifting module 51 includes a lifting cylinder 121 , and the lifting module 51 drives the cutting knife 12 to move up and down by controlling the expansion and contraction of the lifting cylinder 121 .

[0059] refer to image 3 , the first monitoring module 3 includes a first pressure sensor, and the first monitoring module 3 monitors whether the cutting knife 12 has scraps on the side away from the paper through the pressure sensor; When there is pressure on leftover material, the first monitoring module 3 generates pressure monitoring information and sends it out.

[0060] refer to image 3 , the first opening and closing module 31 is used to respond to the pressure monitoring information sent by the first monitoring module 3 and control the opening and closing of the suction fan; when the first opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com