Solid wood composite core board with wood fiber directions being symmetrically staggered and longitudinally and transversely laminated, solid wood composite board and manufacturing method

A technology of solid wood composite and symmetrical interlacing, which is applied in the jointing of wooden veneers, wood layered products, lamination auxiliary operations, etc. Not too obvious and other problems, to achieve the balance of internal stress, increase value, and save wood resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

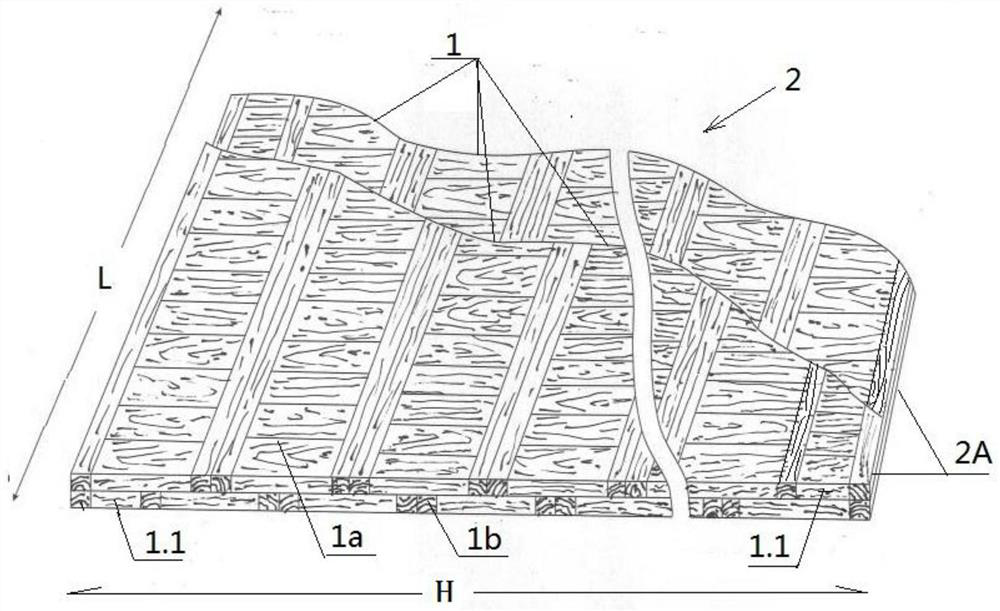

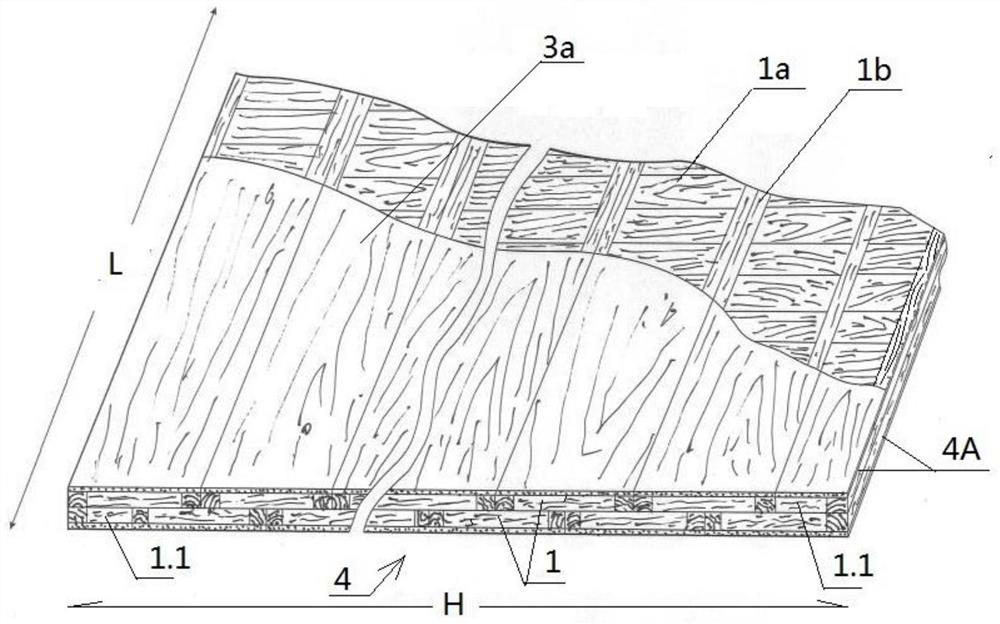

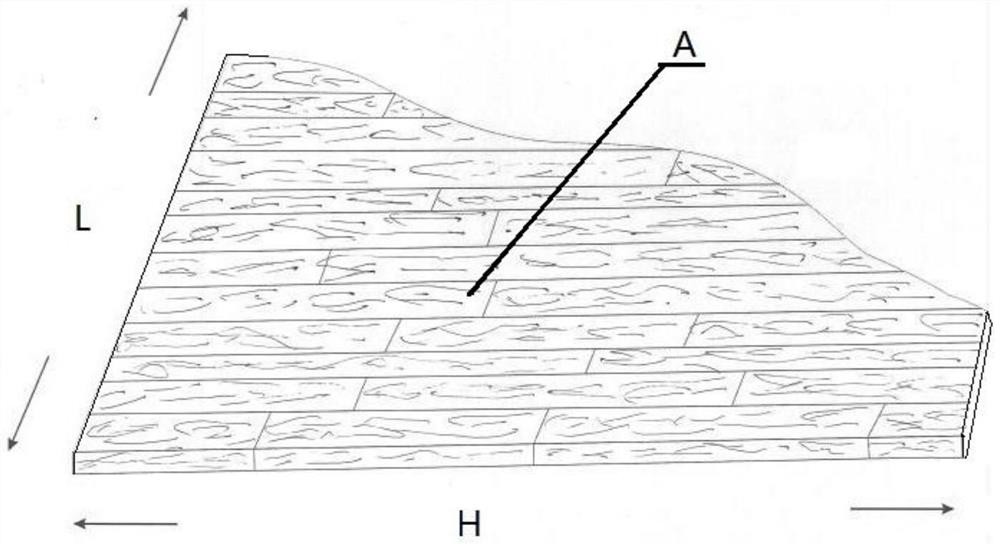

[0072] figure 1 It is a schematic diagram of the solid wood composite core board in which the wood fiber direction is symmetrically staggered and laminated vertically and horizontally: taking the most common composite board core board as an example: the length of the composite board core board = 2440 mm, and the width H = 1220.

[0073] The present invention relates to a solid wood composite core board in which wood fiber directions are symmetrically staggered and laminated vertically and horizontally, including a transverse grain core material and a longitudinal grain core material. , each layer of core material single-layer board is formed by splicing N+1 / 2 core material units 1 horizontally, N is the number of core material unit 1; each core material unit 1 is composed of transverse grain core material unit 1a and one side Or the longitudinal grain core strips 1b on both sides are spliced together, and the transverse grain core material unit 1a is formed by connecting the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com