Oil-based PVDF spraying slurry, diaphragm coated with oil-based PVDF spraying slurry as well as preparation method and application of diaphragm

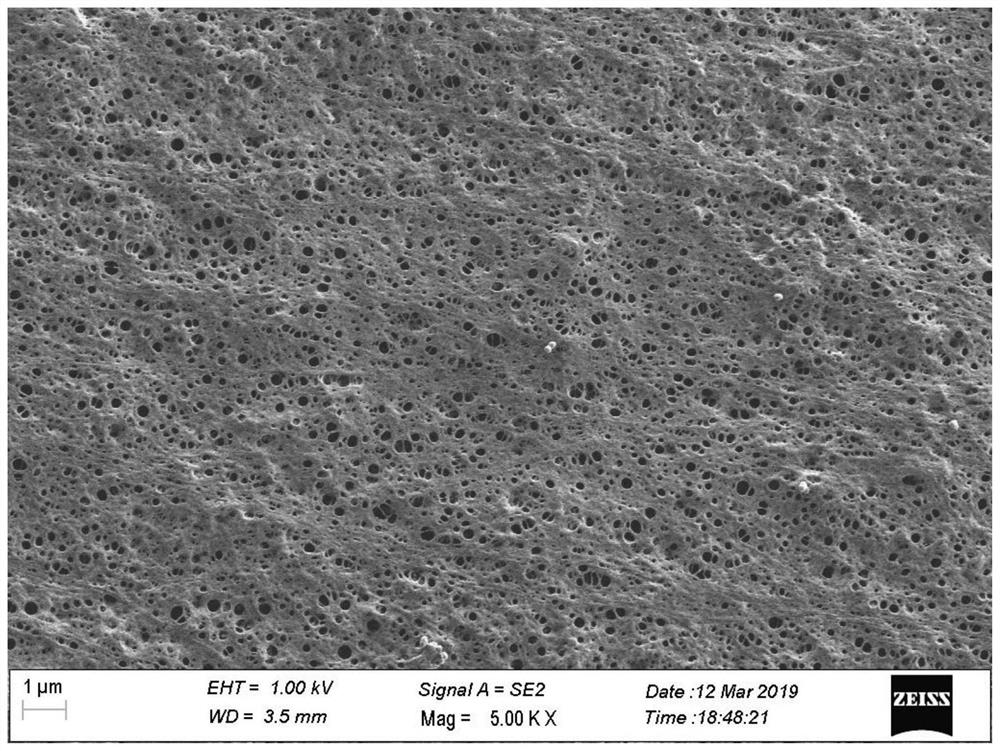

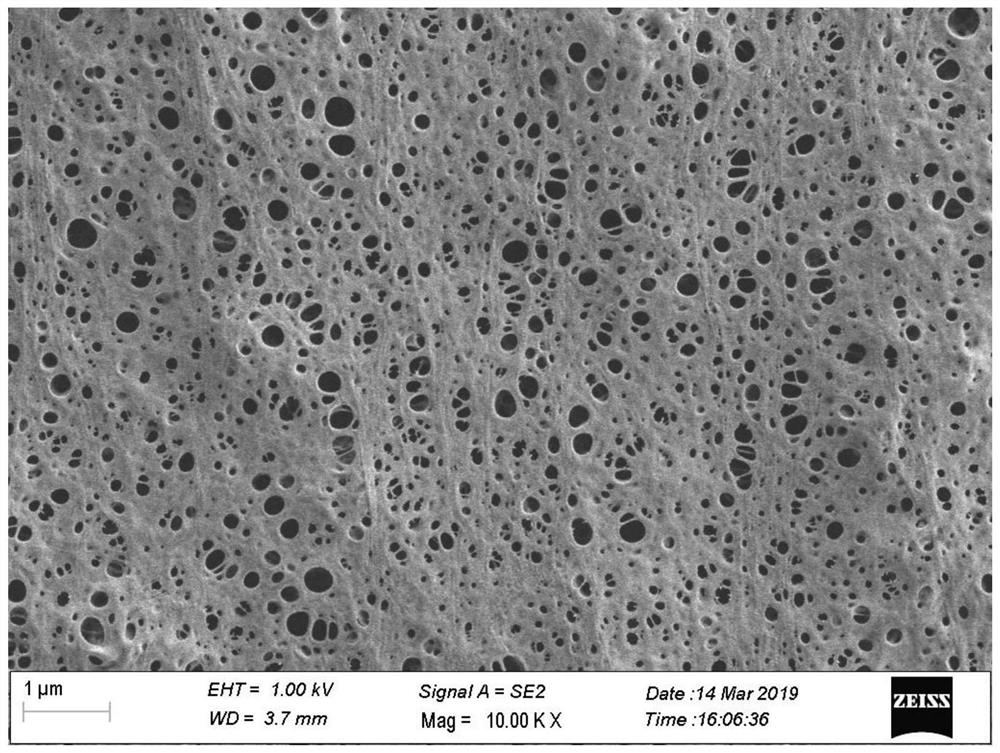

An oil-based and slurry technology, which is applied to coatings, electrical components, circuits, etc., can solve the problems of poor wettability of lithium-ion batteries, and achieve the effects of low air permeability, cost reduction, and small spraying area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method for oil-based PVDF spray slurry, comprising the following steps:

[0037] Stir the polyvinylidene fluoride rapidly for 2 hours and evenly disperse it in the first solvent, then add the second solvent and mix evenly to obtain the oil-based PVDF spray slurry, wherein, in parts by mass, polyvinylidene fluoride, the first solvent and The ratio of the second solvent is 0.2:10:0.1, the first solvent is diethyl ether, and the second solvent is tripropylene glycol.

Embodiment 2

[0039] A preparation method for oil-based PVDF spray slurry, comprising the following steps:

[0040] Stir the polyvinylidene fluoride rapidly for 6h and disperse it uniformly in the first solvent, then add the second solvent and mix evenly to obtain the oil-based PVDF spray slurry, wherein, in parts by mass, polyvinylidene fluoride, the first solvent and The ratio of the second solvent is 1:10:1, the first solvent is ethanol, and the second solvent is isopropanol.

Embodiment 3

[0042] A preparation method for oil-based PVDF spray slurry, comprising the following steps:

[0043] Stir the polyvinylidene fluoride rapidly for 3 hours and evenly disperse it in the first solvent, then add the second solvent and mix evenly to obtain the oil-based PVDF spray slurry, wherein, in parts by mass, polyvinylidene fluoride, the first solvent and The ratio of the second solvent is 0.7:10:0.6, the first solvent is acetone, and the second solvent is deionized water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com