Water basin structure and cabinet assembly

The technology of a sink and a sink body is applied in the field of kitchen appliances, which can solve the problems of occupying a countertop operation space, occupying a large space for a water purifier, and a large space occupancy rate for a water purifier, so as to increase the space utilization rate and facilitate arrangement and placement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

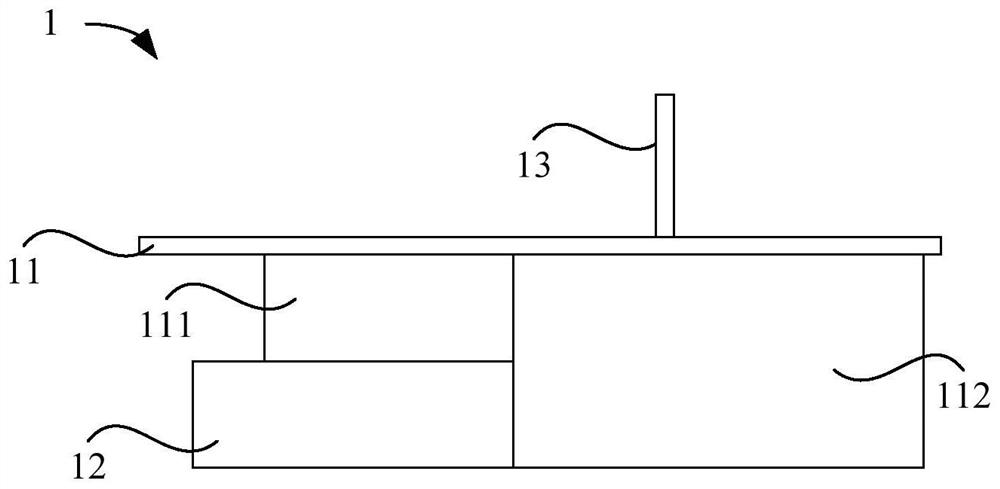

[0060] Such as figure 1 As shown, an embodiment of the present invention provides a water tank structure 1, including a water tank body 11 and a water outlet device 13 arranged on the water tank body 11, wherein the water tank body 11 includes a first water tank 111 and a second water tank 111 arranged side by side. Water tank 112, the groove depth of the first water tank 111 is relatively shallow, and the groove depth of the second water tank 112 is relatively deep, and when setting, the notches of the first water tank 111 and the second water tank 112 are flush, so that the purification device 12 It is arranged in the dislocation space where the bottom of the first water tank 111 is higher than the bottom of the second water tank 112 .

[0061] Wherein, the first water tank 111 is a soaking area, and the second water tank 112 is a cleaning area.

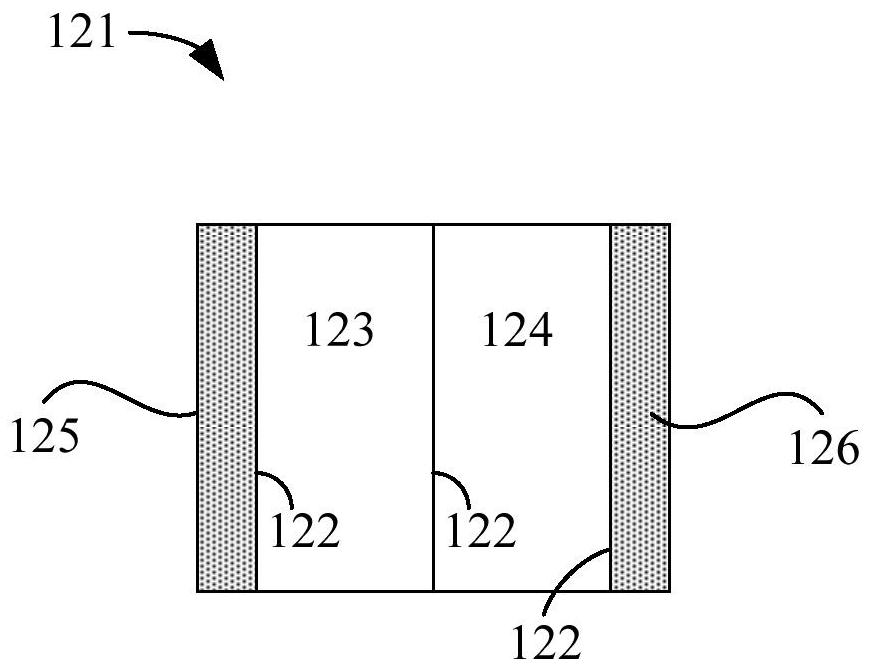

[0062] Further, as image 3 As shown, the purification device 12 includes an electrodialysis membrane stack 121 having a plural...

Embodiment 2

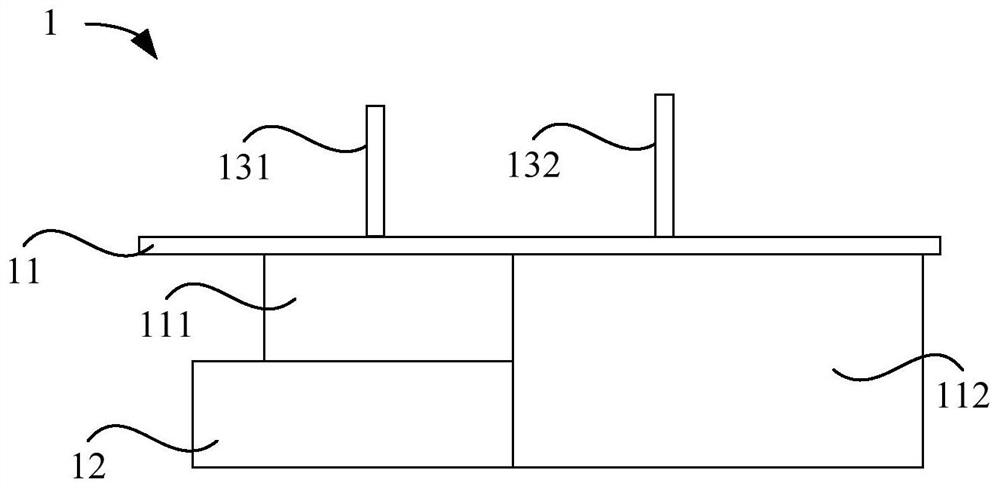

[0066] Such as figure 2 As shown, on the basis of Embodiment 1, the water tank structure 1 is a double-faucet water outlet structure, and the first water tank 111 and the second water tank 112 are respectively provided with a drinking water joint 131 and a water joint 132, and a pre-filter is also provided. 127 and a post-filter 128, wherein the pre-filter 127 can perform preliminary filtration on the fluid flowing into the purification device 12, and the post-filter 128 can filter the ion concentration in the first processing chamber 123 and the second processing chamber 124. The lower one is subjected to secondary filtration before being exported to further improve the water quality of the fluid to meet the water quality needs of users for drinking.

[0067] Among them, such as Figure 4 As shown, the water flowing out through the drinking water connector 131 flows out through the pre-filter 127, the electrodialysis membrane stack 121 and the rear filter 128 in sequence, a...

Embodiment 3

[0074] Such as figure 1 and Figure 7 As shown, on the basis of Embodiment 1, the water tank structure 1 is a single faucet water outlet structure, and a joint structure 133 is provided on the second water tank 112, and a pre-filter 127 and a post-filter 128 are also provided, wherein , the pre-filter 127 can pre-filter the fluid flowing into the purification device 12, and the post-filter 128 can filter the ion concentration in the first processing chamber 123 and the second processing chamber 124 before exporting to the outside. Perform secondary filtration to further improve the water quality of the fluid to meet the drinking water quality needs of users.

[0075] Among them, such as Figure 4 As shown, the joint structure 133 can be selectively connected to the rear filter element 128 or the pre-filter element 127, so that drinking water and daily water can be switched through one joint structure 133, which is more conducive to the miniaturization design of the sink stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com