Anti-deformation and shock-absorbing protection structure at top of tunnel

A protection structure and anti-deformation technology, which is applied in tunnels, tunnel linings, shaft linings, etc., can solve the problems of difficult control of surrounding rock deformation, complex design and construction technology, and main structure damage, so as to improve the self-bearing capacity of soil and anti-corrosion. Deformation capacity, construction progress is safe, efficient and reasonable, and the effect of seismic support vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

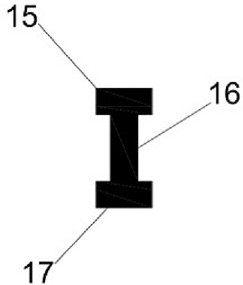

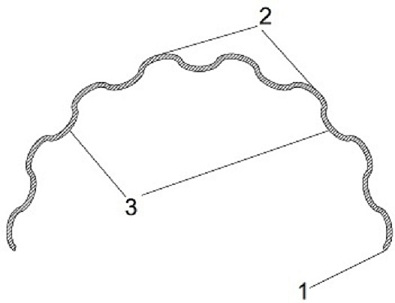

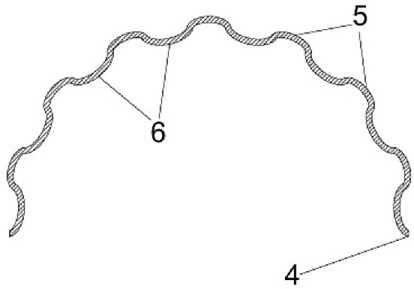

[0023] Example: such as Figure 1~Figure 6 As shown, a kind of anti-deformation and shock-absorbing protection structure at the top of the tunnel, including the outer support arch reinforcement plate 1, the middle and outer support arch reinforcement plate 4, the middle and inner support arch reinforcement plate 7, and the inner support arch reinforcement plate 10. Coordinating connection and fixing rod 13, locking and reinforcing screw 14, hoop structure 15, built-in anti-seismic buffer setting layer 18, built-in mixed support strengthening medium layer 19, side bearing support pile structure 20, connecting support and fixing plate 21, The inner support is fixedly connected to the bottom plate 22, and the outer support is fixedly connected to the top plate 23. The outermost layer of the anti-deformation and shock absorption protection structure at the top of the tunnel is provided with an outer support and fixedly connected to the top plate 23, and the inner side of the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com