Heat exchanger

A technology of heat exchangers and heat exchange areas, applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., can solve the problems of low heat exchange efficiency, deterioration of heat exchange effect, poor heat exchange effect, etc. Achieve the effect of improving heat transfer performance, increasing heat transfer area and flow disturbance, and slowing down the reduction of flow channel cross section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

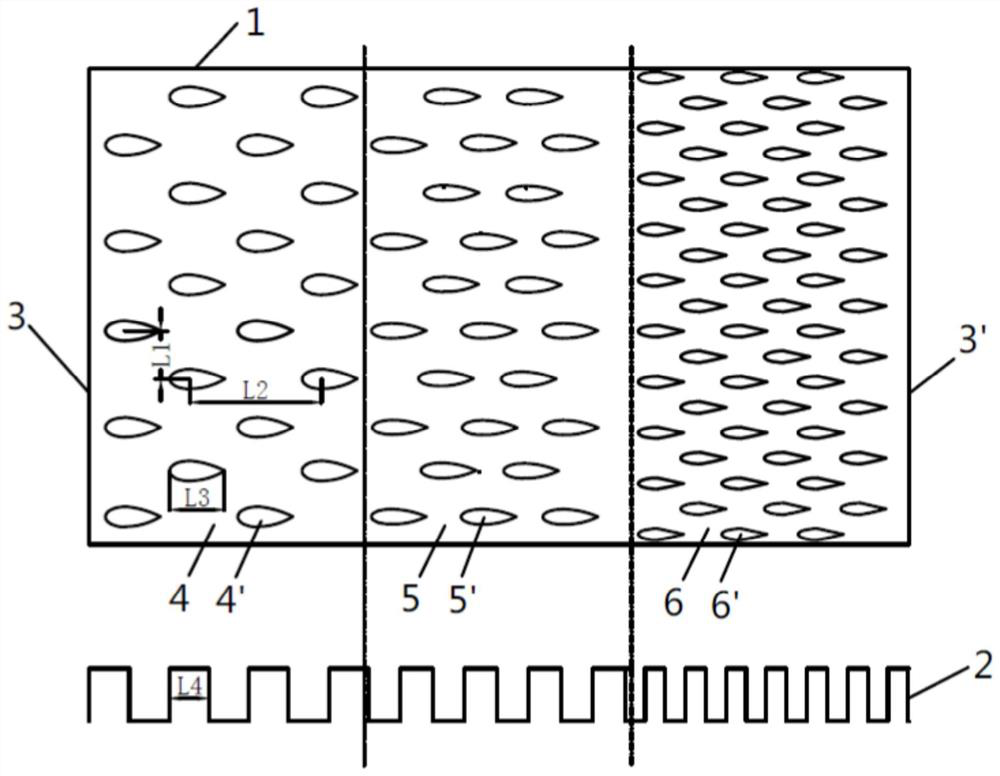

[0041] See Figure 1-Figure 3 , the present embodiment provides a plate-fin air-cooled heat exchanger with variable cross-section microchannels, including:

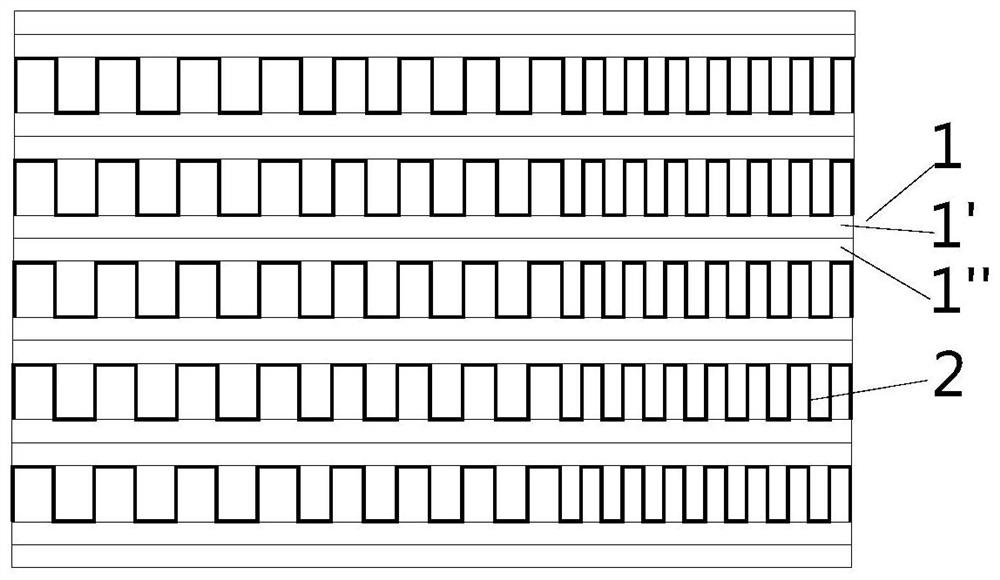

[0042] Several heat exchange plates (1) on the hot side, several rectangular corrugated fins (2) on the cold side, the heat exchange plates (1) and the rectangular corrugated fins (2) are stacked alternately and connected by diffusion welding. The rectangular corrugated fins (2) of the heat exchanger adopt air as the cooling medium (or called cold-side working medium). The hot-side working fluid may be, for example, carbon dioxide working fluid.

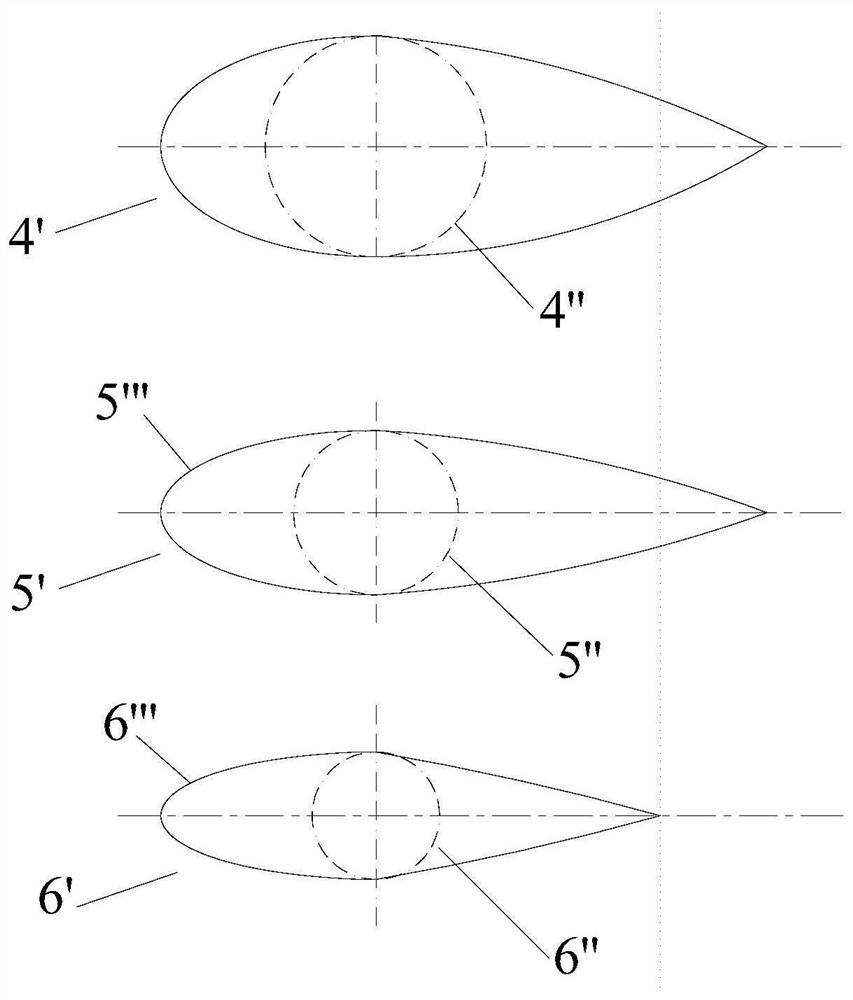

[0043] Wherein, the heat exchange plate (1) is composed of an upper plate (1') and a lower plate (1"), along the flow direction of the working fluid on the hot side, the lower surface of the upper plate (1') and the lower plate (1") The upper surface of the upper surface is sequentially provided with heat exchange plate inlet (3), general heat exchange area (4), level I enhanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com