Mold production method, and molded article production method using same

A manufacturing method and technology of a molded body, which are applied to the manufacture of molds and the manufacturing field of molded bodies using the manufacture, can solve the problems of large curing shrinkage rate and the like, and achieve the effect of excellent surface accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0144] Coat the mold with an ultraviolet curable composition (trade name "CELVENUS OUH106", containing a cationic curable compound and a photocationic polymerization initiator, and 80% by weight of the total amount of the cationic curable compound is an epoxy resin (containing a multifunctional alicyclic Formula epoxy compound) manufactured by Daicel Co., Ltd., closed the mold from above with a transparent substrate. Then, UV irradiation (80mW × 30 seconds) was carried out, and then, mold release was carried out to obtain a molded body ( Figure 6 ). In the obtained molded body, bending displacement occurred from the central part of the side surface to the lower central part.

Embodiment 1

[0145] Example 1 (Study on Bending from the Center to the Lower Center of the Side of the Molded Body)

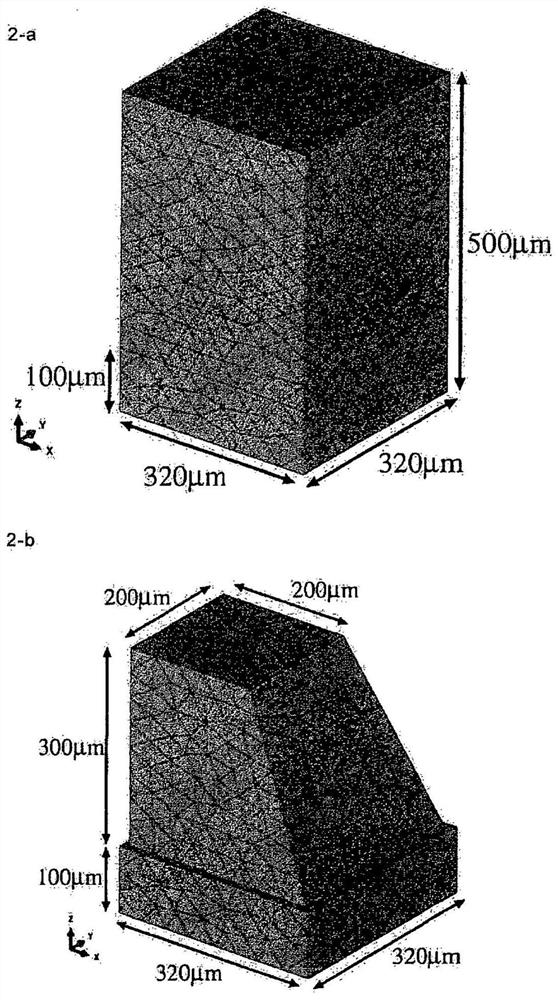

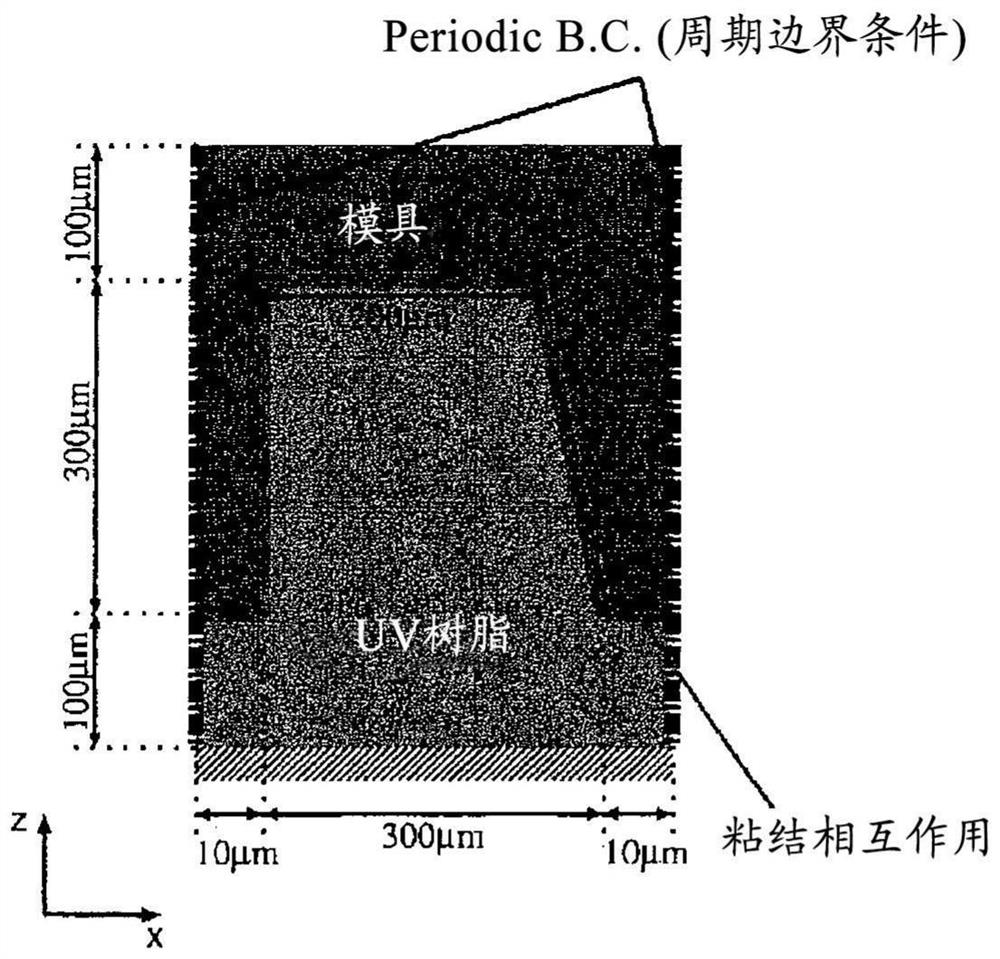

[0146] Modeling was performed by replacing curing shrinkage caused by irradiating the ultraviolet curable composition with ultraviolet rays to shrinkage and solidification caused by cooling the thermoviscoelastic body.

[0147]

[0148] Thermal linear expansion coefficient: 0.0001K -1

[0149] Instant Young's modulus: 250MPa

[0150] Instant Poisson's Ratio: 0.3

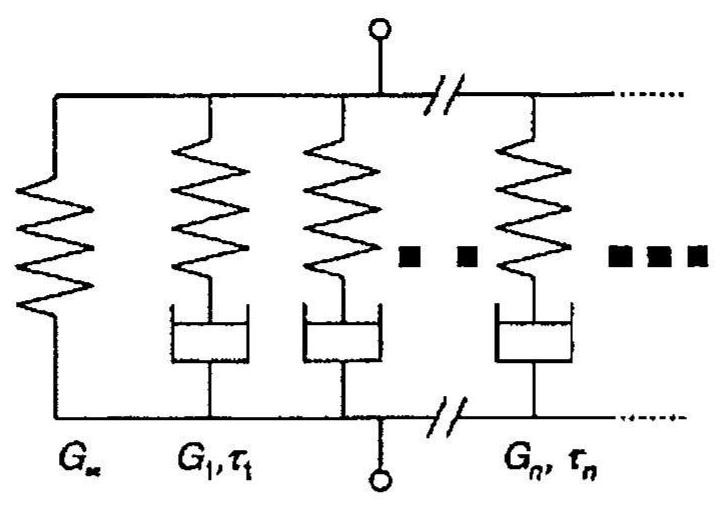

[0151] Generalized Maxwell model:

[0152] g 1 =0.99999

[0153] τ 1 =1.0sec.

[0154] Time-temperature conversion rule (WLF equation):

[0155] θ 0 : 25°C

[0156] C 1 =10

[0157] C 2 : 100°C

[0158] Additionally, the mold was modeled based on Neo-Hooke elastomers.

[0159]

[0160] Initial Young's modulus: 5MPa

[0161] Initial Poisson's ratio: 0.49

[0162] The finite element analysis using the tetrahedral quadratic modified hybrid element (C3D10MH) of ABAQUOS / Standard was carried out acc...

Embodiment 2

[0177] The finite element analysis was performed under the same conditions as in Example 1 except that the initial Young's modulus of the mold was changed to 1000 GPa. As a result, the sectional view perpendicular to the y-axis at the time t=100s of Step2 ( Figure 10 ), no bending at the central portion of the side of the molded body was observed.

[0178] From this, it can be confirmed that the tube formation due to the flexibility of the mold is involved in the display of the curvature of the central portion of the side surface of the molded body.

[0179] From the results of Examples 1 and 2, and Experimental Example 1, it was confirmed that the cure shrinkage of the resin and the deformation of the mold accompanying the cure shrinkage were involved in the development of the curve from the center to the lower center of the side of the molded body. In addition, it was confirmed that the deformation of the molded body can be accurately simulated when the calculation is perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com