Method for calculating for products of coal liquefaction reaction

A liquefaction product, coal liquefaction technology, applied in the preparation of liquid hydrocarbon mixtures, petroleum industry, etc., can solve the problems of large research costs and time, and achieve the effect of saving money and time, and optimizing the shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

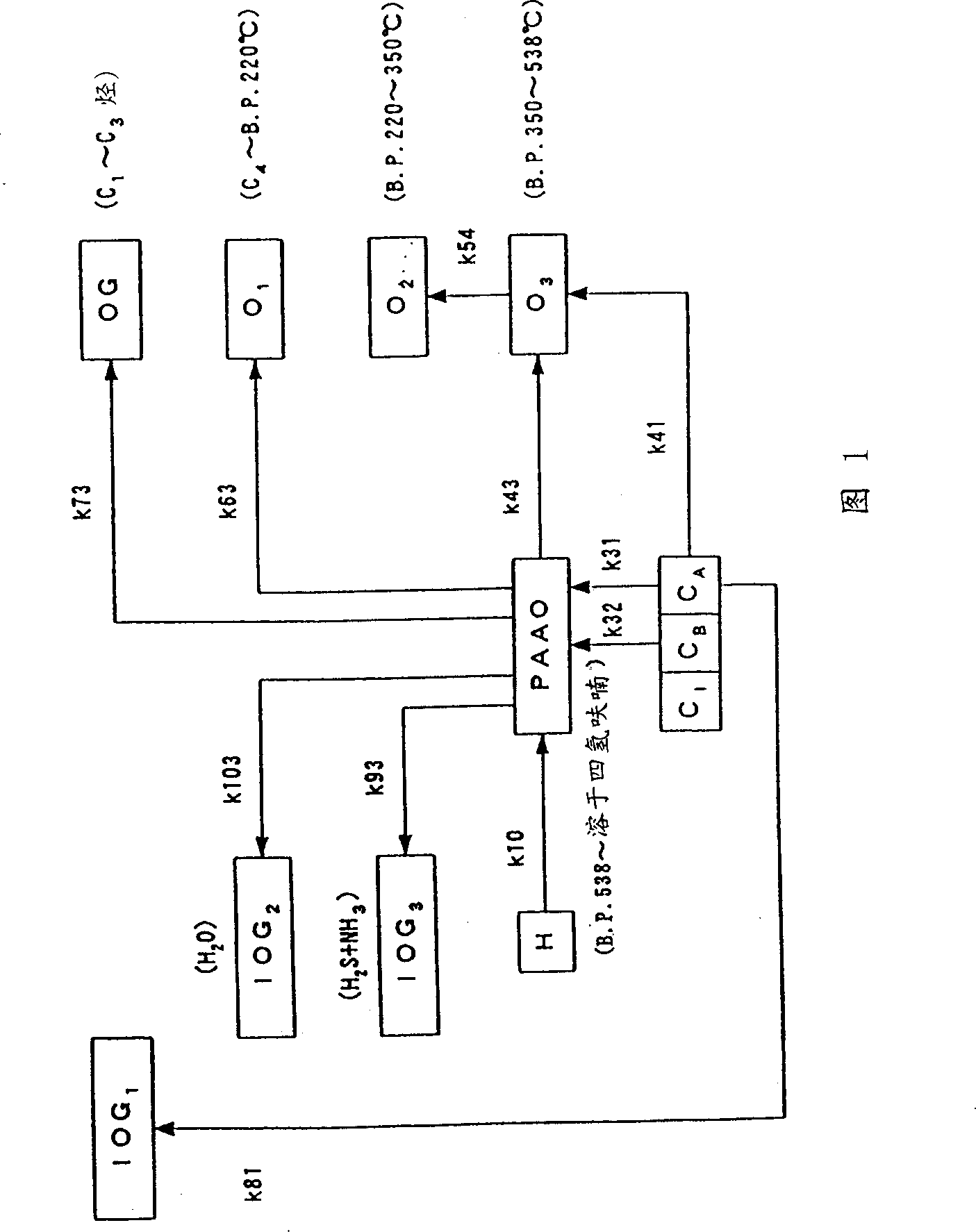

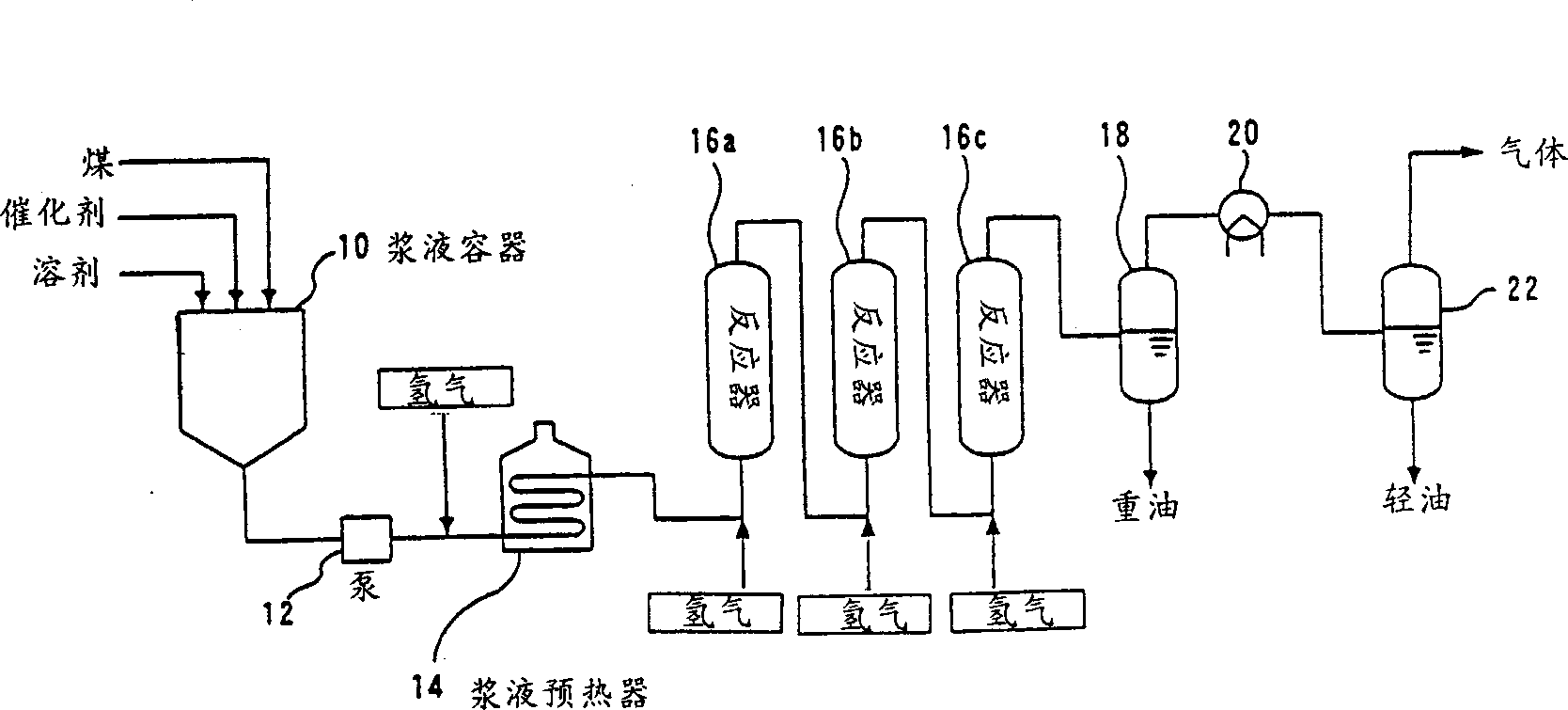

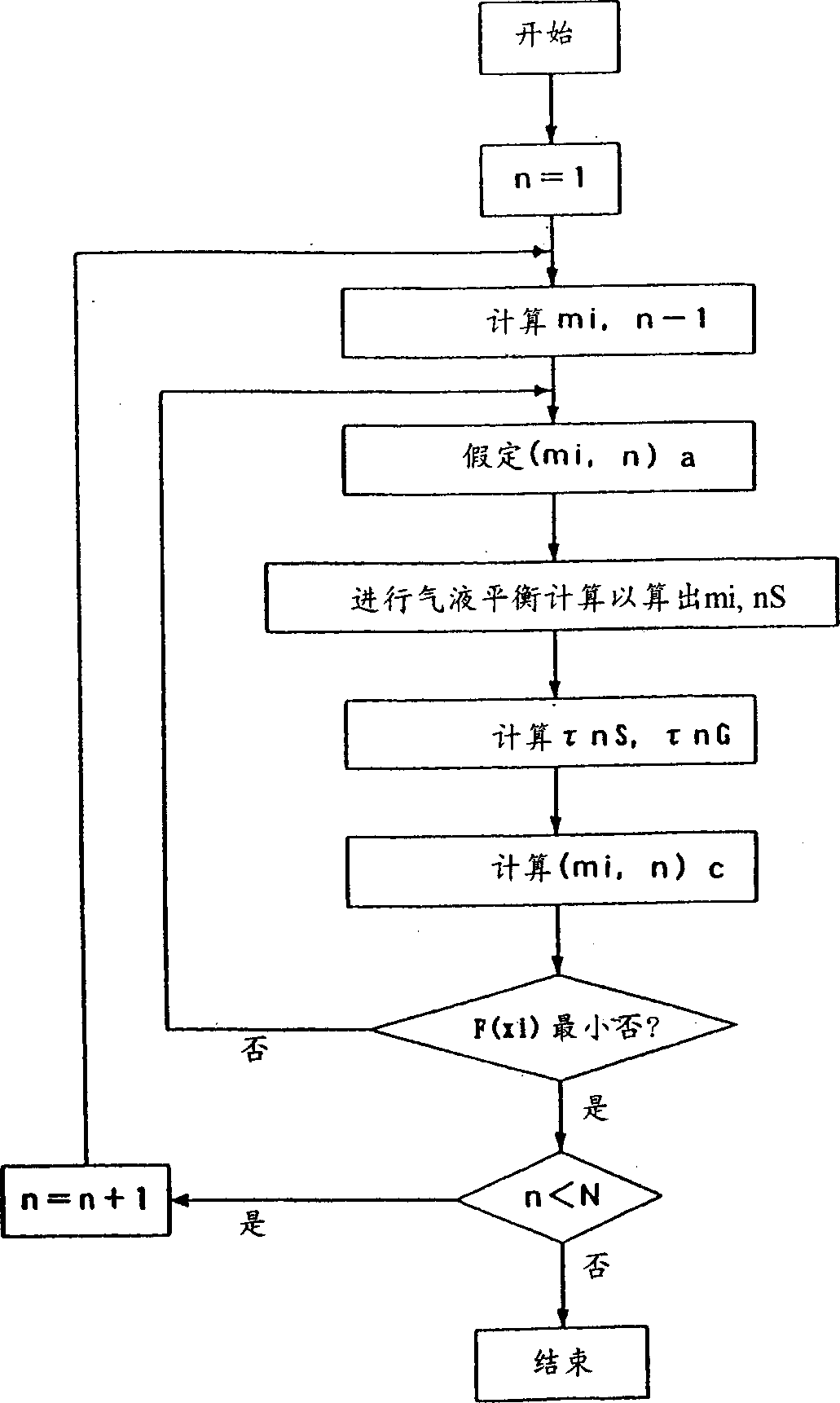

[0187] The method of estimating the flow rate at the outlet of a coal liquefaction reactor consisting of three sequentially connected bubble columns is now exemplified by the program of the present invention. The kij values of raw coal A and [C A ], [C B ] and [C I ] values are obtained through experiments. Tables 3 and 4 show the dimensions of the bubble column, the reaction temperature, the reaction pressure and the flow rate mi,0 of each component at the inlet of the first column.

[0188] first tower

second tower

third tower

Inner diameter of reactor cm

The effective length of the reactor cm

The internal volume of the reactor L

Gas space velocity cm / s

Slurry space velocity cm / s

Gas retention value-

Reactor temperature °C

Reactor pressure kg / cm 2

Injected hydrogen gas kg / h

100.0

1100.0

8640.0

5.9

0.20

0.387

3442

476

171

...

Embodiment 2

[0199] The procedure of the present invention is used to calculate reaction rate constants based on actual measurements of the flow velocity at the outlet of a coal liquefaction reactor consisting of three sequentially connected bubble columns. The raw coal [C A ], [C B ] and [C I ]value. A slurry preheater is also arranged in the front section of the coal liquefaction reactor, which is used to heat the coal slurry to a temperature close to the reaction temperature before the slurry enters the first reaction tower. During this warm-up phase C A The reaction of conversion into liquefied products, that is, the three routes are , , The reactions are almost complete, therefore, these reactions are ignored in the analysis of the reaction rate. As a result, the values of K31, K41 and K81 could not be obtained from the analysis of the reaction rate.

[0200] Table 6 shows the reaction rate constants for coal B obtained from the analysis of the reaction rates. O...

Embodiment 3

[0206] Among the reaction rate constants shown in Table 1, the reaction rate constants K32, K43, K54, K63, K73, K103, K93, K81 and K10 are obtained by the calculation method of the above-mentioned direct method, which is based on the use of three sequentially connected A reactor consisting of a bubble column (reaction vessel) while the reaction model shown in Fig. 1 is calculated for Adaro coal, a lignite, Tanitohalm coal, a sub-bituminous coal with a high degree of coalification, and Ikeshima coal, a bituminous coal. owned.

[0207] Table 8 shows the analytical value of each component in Adaro coal, Tanitohalm coal, and Ikeshima coal, and the reaction rate constant calculated using the above-mentioned reaction model and actually measured component values obtained by liquefaction reaction treatment.

[0208] coal type

[0209] "VM" in the first column of Table 8 represents the ratio of dimensionless volatile components contained in dry coal. Likewise, "FC" indicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com