Novel straw returning machine

A new straw and new technology, applied in the field of new straw returning machines, can solve the problems of low work efficiency, high labor intensity, time-consuming and labor-intensive, etc., and achieve the effect of reasonable structure and reduced work burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

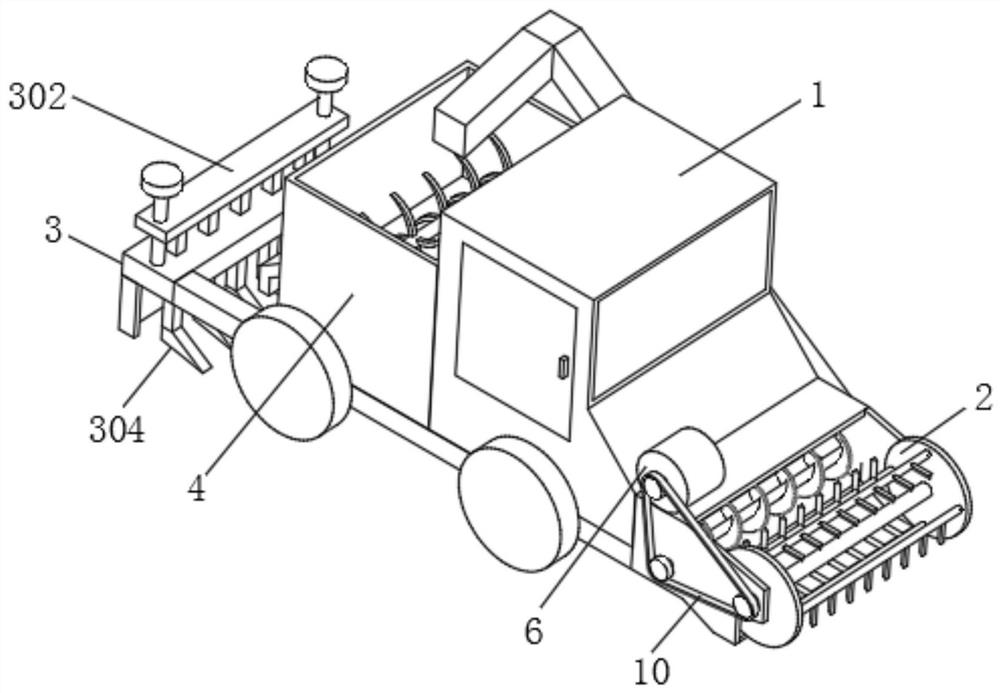

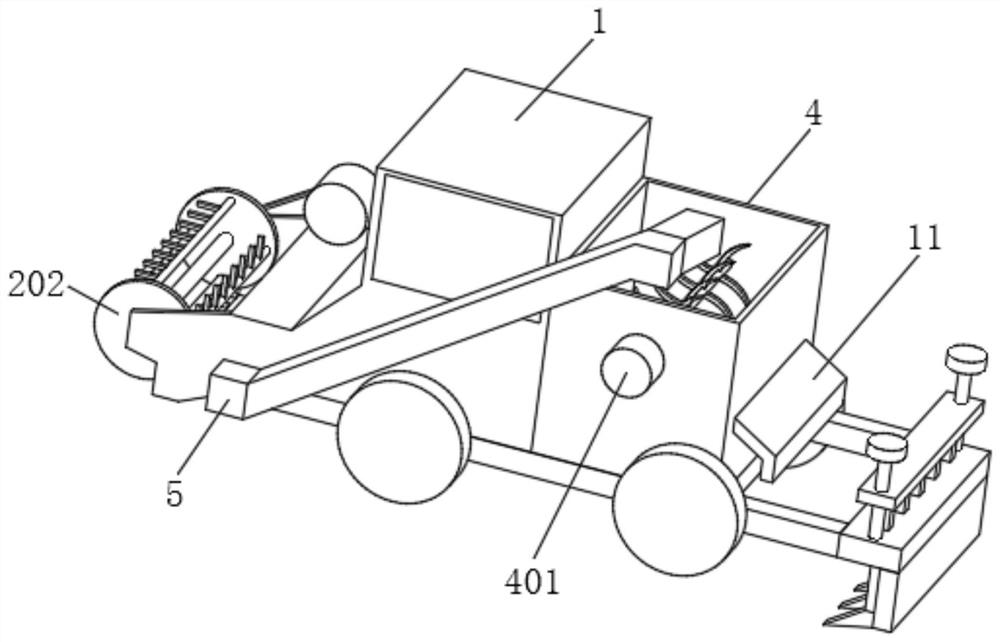

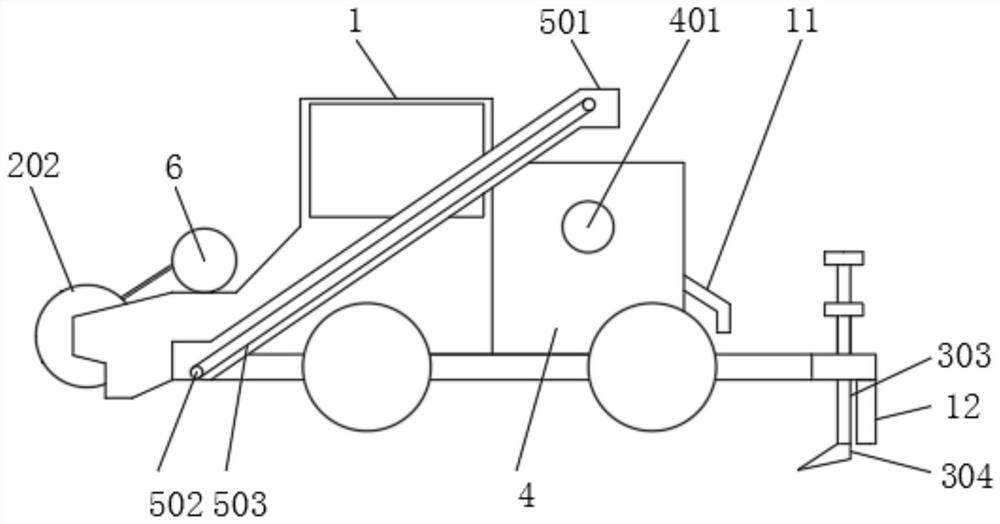

[0037] Example: Reference figure 1 and figure 2 A new type of straw returning machine is shown, including a locomotive 1, a harvesting mechanism 2, an excavating mechanism 3, a storage box 4 and a transmission mechanism 5. The front end of the locomotive 1 is provided with a harvesting mechanism 2, and the rear end of the locomotive 1 is fixedly connected to There is an earth-digging mechanism 3, and the top of the locomotive 1 is fixedly connected with a material storage box 4, and the material storage box 4 can be any box structure in the prior art, such as a metal box.

[0038] The material storage box 4 is provided with a stirring mechanism, a transmission mechanism 5 is provided between the harvesting mechanism 2 and the material storage box 4, and the top of the locomotive 1 is fixed with a harvesting motor 6, which can be any one of the prior art Motor, for example, the model is: 5IK120RGN motor.

[0039]The output shaft of the harvesting motor 6 is fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com