Low-dust ensiling peanut combine harvester

A combine harvester and silage technology, applied in the field of peanut harvesting machinery and equipment, can solve the problems of low harvesting efficiency, easy generation of dust, noise and environmental pollution, and achieve the effect of high operating efficiency, compact structure and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1. At present, domestic peanut harvesting is mainly carried out by manual and small-scale agricultural machinery, that is, after the peanuts are mature, they are first excavated as a whole, and then the process of drying, picking and removing the tails and screening, etc., is easy to generate dust, noise and environmental pollution during harvesting. , the harvesting efficiency is relatively low, and at the same time, the peanut harvesting machinery that is single, inefficient, and prone to environmental pollution can no longer meet the current demand for peanut harvesting.

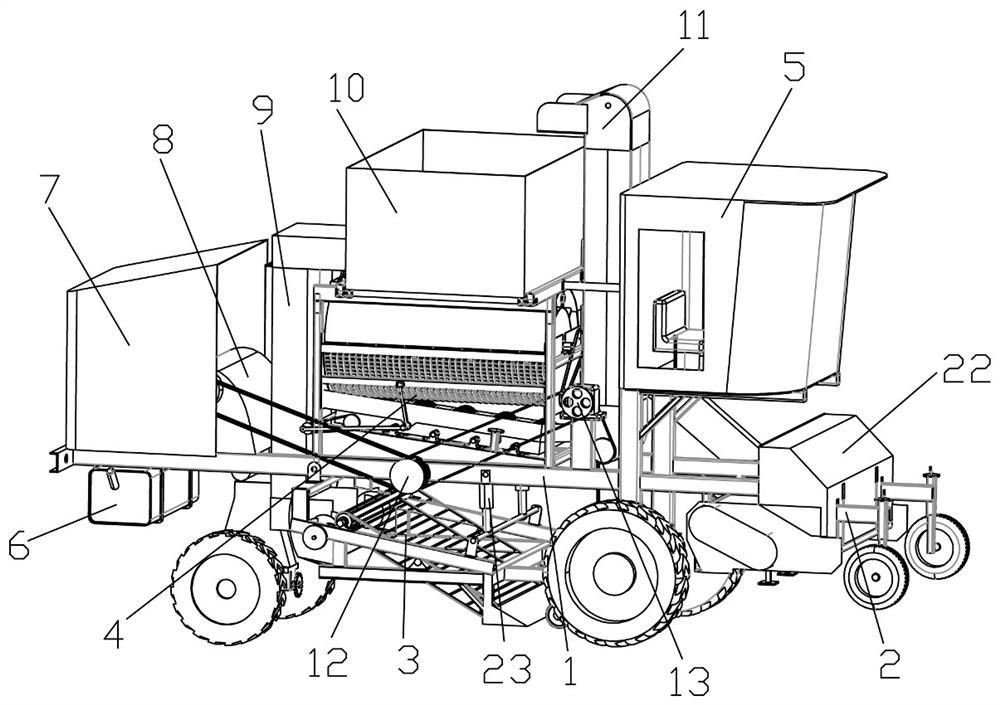

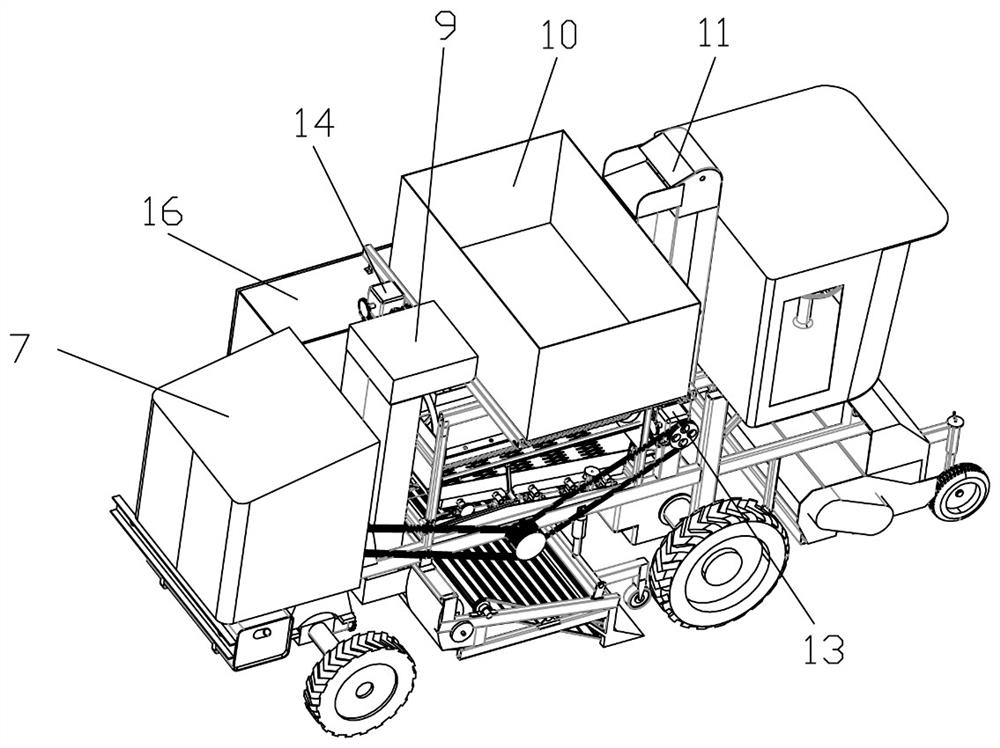

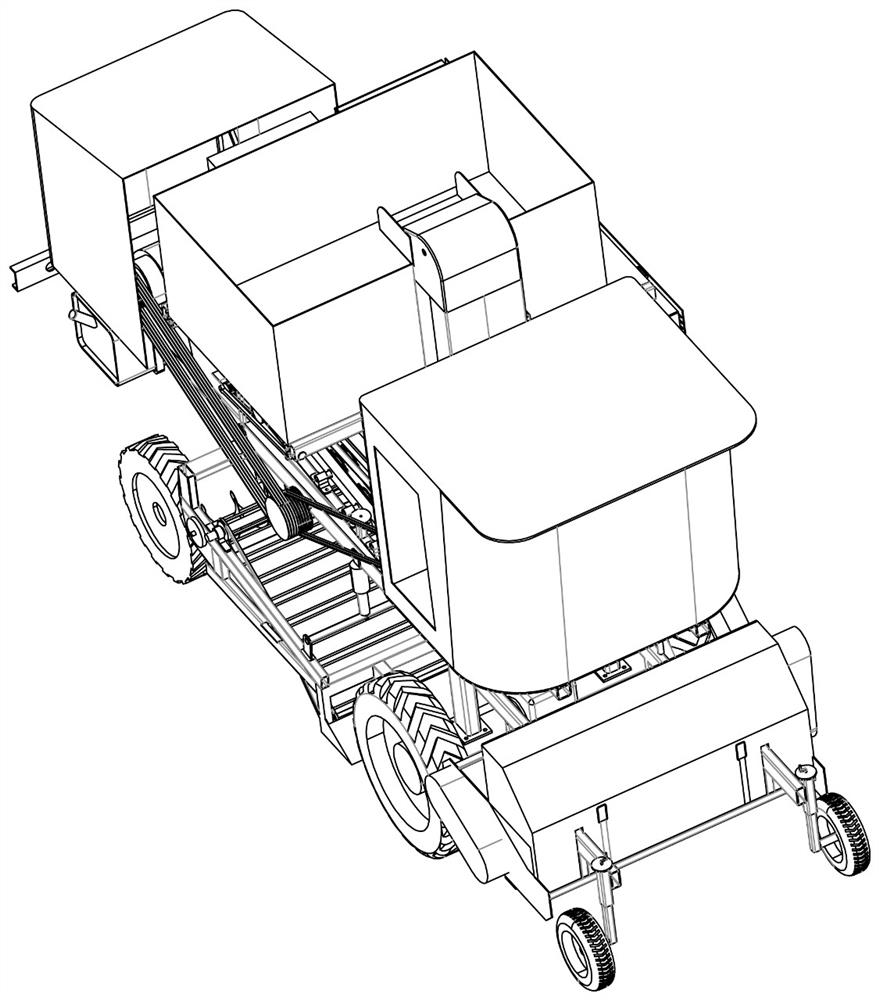

[0033] In view of the above problems, the present embodiment provides a low-dust silage peanut combine harvester, such as Figure 1-2 Shown, comprise chassis 1, the bottom of chassis 1 is provided with traveling wheel, is fixedly installed with motor 8 at the rear end of chassis 1, is fixed with belt pulley on the output shaft of motor 8, and the outer side of motor 8 is fixed with housing 7...

Embodiment 2

[0037] Embodiment 2, a low-dust silage peanut combine harvester in this implementation will be described centering on the differences from Embodiment 1.

[0038] In this embodiment, a horizontal plate 411 is fixed in the fruit picking and cleaning frame 401, and the shaft rod on the right side of the rear end of the picking and cleaning plate 407 extends out of the shaft seat and is fixed with a pulley. Connecting shaft 413 is fixedly installed, and the right end of connecting shaft 413 is fixed with the 4th belt pulley 415, and the 4th belt pulley 415 is connected with the belt pulley transmission on the right side of tail-picking cleaning plate 407 rear end, and connecting shaft 413 is provided with long Hinged rod 412, the tail end of long articulated rod 412 is hinged with connecting shaft 413, and the head end is hinged on the outer surface of tail-picking cleaning plate 407, and short articulated rod 416 is hinged on long articulated rod 412, and short articulated rod 416...

Embodiment 3

[0039] Embodiment 3, a low-dust silage peanut combine harvester in this implementation will be described centering on the differences from Embodiment 1.

[0040] In this embodiment, the cutting seedling fixing wheel frame 208 fixedly welded at the front end of the cutting seedling silage frame 201 is telescopic, and the cutting seedling fixing wheel 204 is installed at the bottom of the wheel frame, and the cutting seedling fixing wheel frame 208 The top of the top is provided with adjustment handle 205, can regulate the height of cutting seedlings and solid wheel 204 by adjusting adjustment handle 205, can make cutting seedlings and solid wheel better compression peanut seedling tendril by regulating the height of cutting seedlings solid wheel 204.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com