Quick and efficient betel nut drying system

A drying system, betel nut technology, applied in the fields of application, food processing, food science, etc., to achieve the effect of improving drying quality, reducing emissions, and accelerating drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

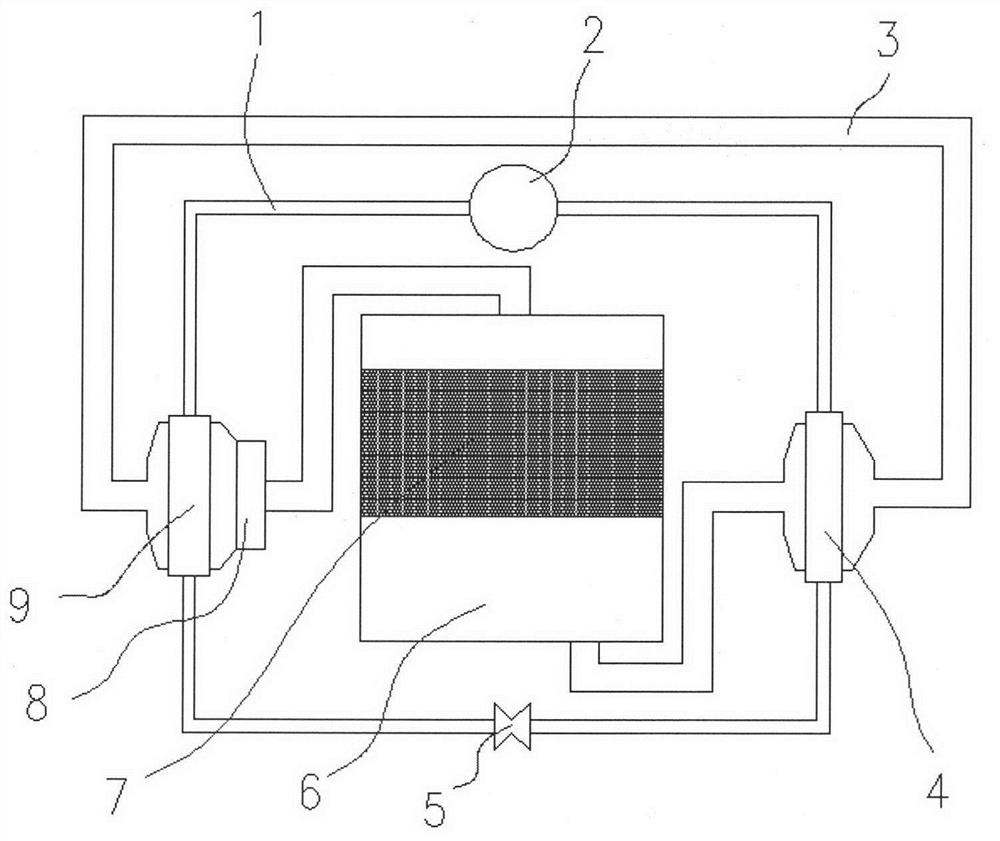

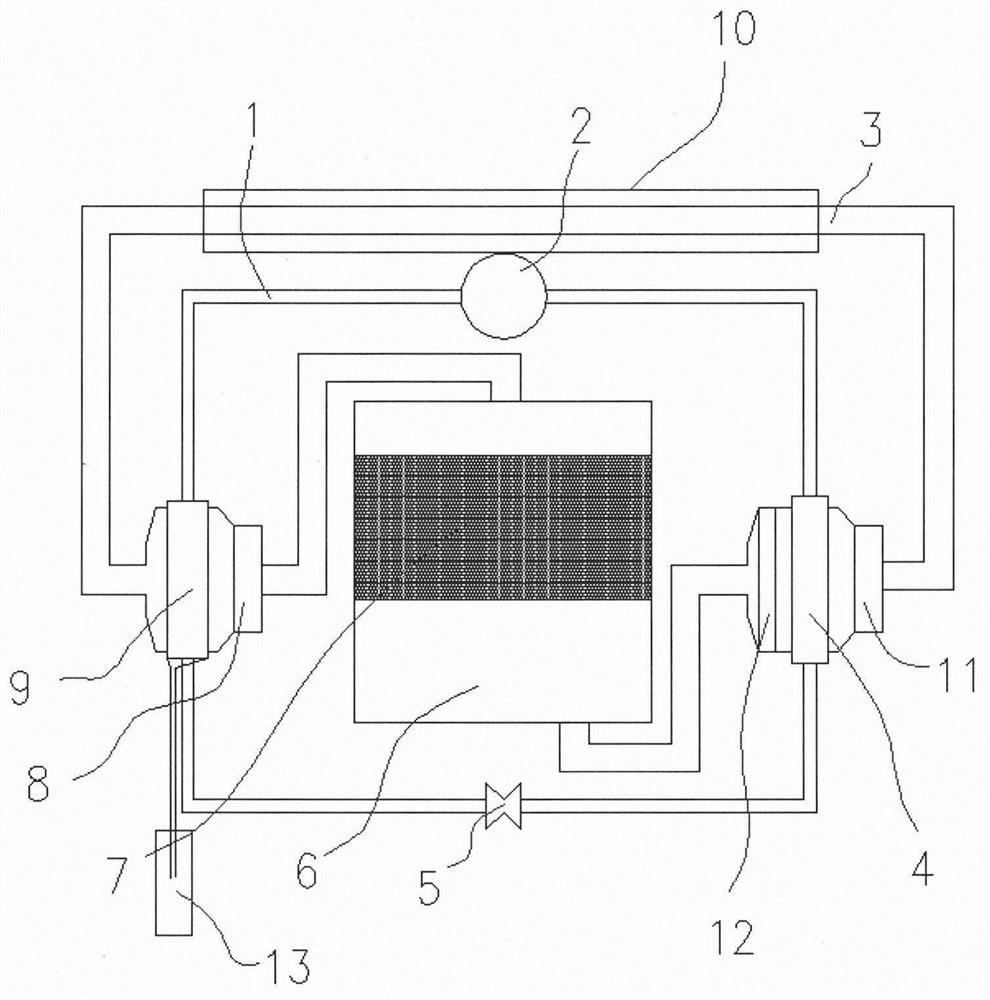

[0020] In order to fully understand the technical content of the present invention, below in conjunction with specific embodiment and description accompanying drawing (accompanying drawing only shows the structure of the present invention by schematic diagram, and its shape, size, proportion are different from actual application) to the present invention The technical solution is further introduced and explained, but not limited thereto.

[0021] Such as Figure 1 to Figure 2 Shown, a kind of fast high-efficiency betel nut drying system of the present invention comprises refrigerant pipeline (1), compressor (2), air pipeline (3) condenser (4), expansion valve (5), drying chamber ( 6), betel nut (7), blower fan (8) and evaporator (9), between compressor (2), condenser (4), expansion valve (5), evaporator (9) with refrigerant pipe ( 1) connected to form a refrigerant working cycle from the compressor (2) to the condenser (4), the expansion valve (5) to the evaporator (9) and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com