Refrigerating machine room pipeline device integrated set rail type installation device and method

A technology for a refrigeration machine room and an installation device, which is applied to the braking device, hoisting device, and hoisting device of hoisting equipment, etc., can solve the problems of low labor productivity, rework, and reduce the progress of project installation, so as to reduce installation technical requirements and improve installation. Construction quality, reduce the effect of high working surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

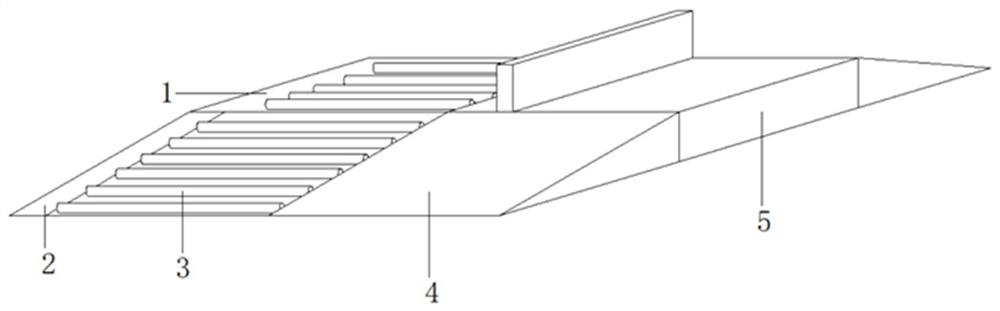

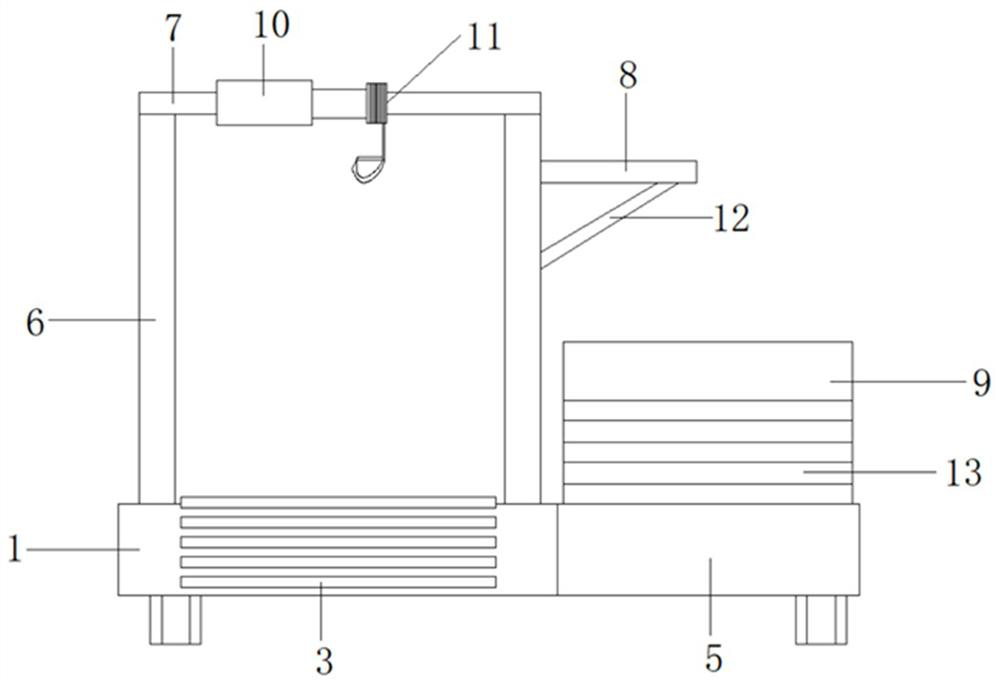

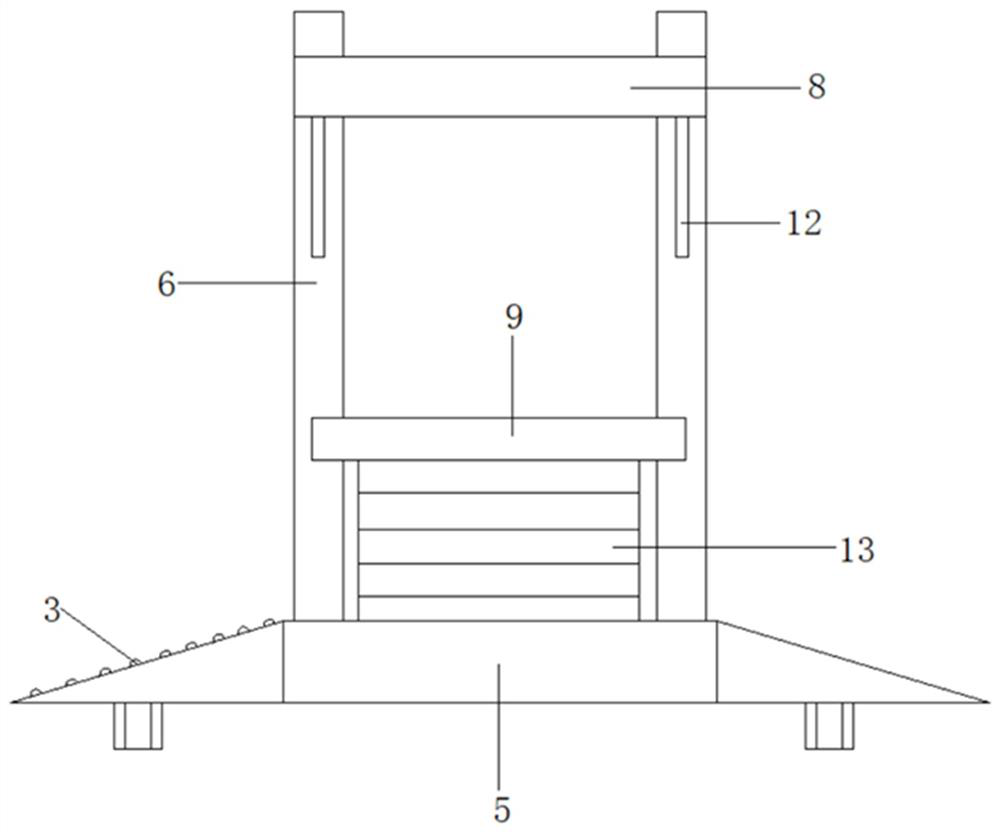

[0038] Using BIM technology, carry out 1:1 physical modeling of equipment, pipelines, valves, etc. in the prefabricated computer room, set parameters for electromechanical equipment, pipelines, supports and hangers, and organize professional engineers to carry out BIM comprehensive wiring deepening plan for the computer room The design and deepening plan need to be approved by the supervisor and the designer of the construction party. Combined with the BIM integrated wiring model, on-site and process transportation conditions, on-site installation conditions and factory processing conditions, etc., the corresponding integrated module samples are determined, and the BIM prefabrication software is used to export and process. The drawings are processed in the factory, and the mechanized component processing is carried out in the prefabrication processing factory. Finally, the corresponding integrated modules are assembled according to the large samples of the integrated modules.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com