Sectional conveying and sectional heating type double-sided machine

A technology of segmented heating and double-sided machine, applied in the direction of machining/deformation, etc., can solve the problems of poor adhesion between pre-printed paper and pitted paper, poor ventilation of conveyor belt, and poor wire drawing and scratching on the surface of the carton.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

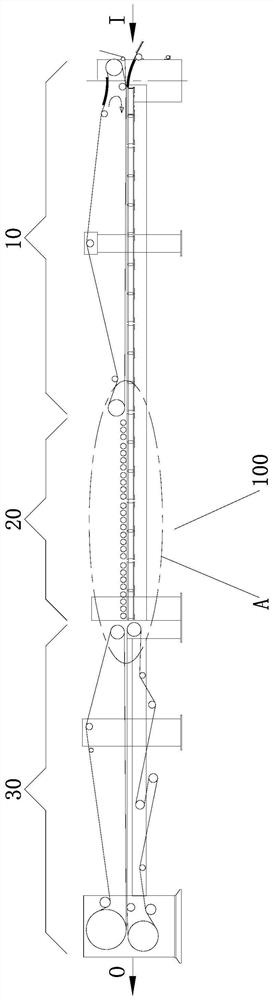

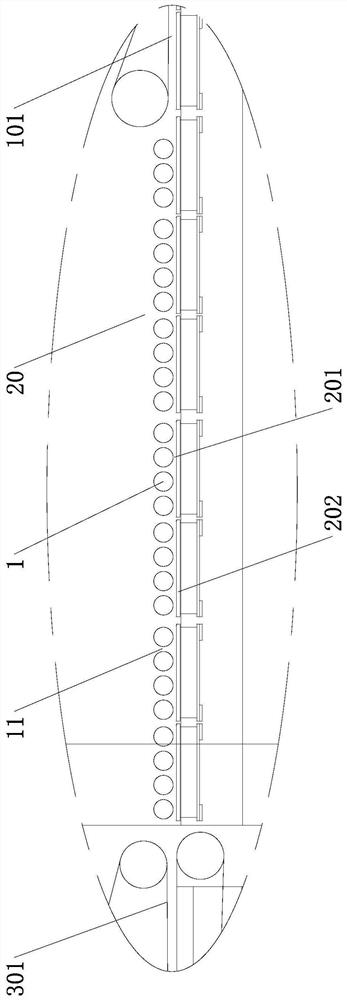

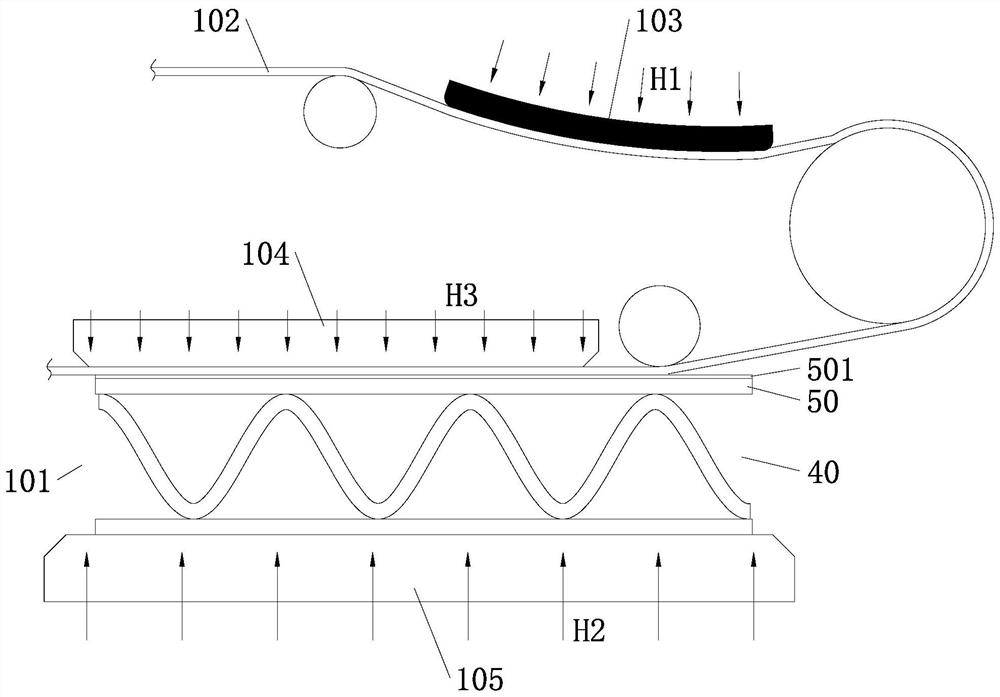

[0048] see figure 1 , figure 2 , Figure 5 , Figure 6 and Figure 7As shown, a segmented transfer and segmented heating type double-sided machine 100 includes a front hot plate transfer part 10 and a rear transfer part 30, and a ventilating heating device is arranged between the front hot plate transfer part 10 and the rear transfer part 30 Transition section 20, ventilation heating transition section 20 is provided with ventilation heating channel 201, the upper and lower sides of ventilation heating channel 201 are provided with heat sources, and the upper side of ventilation heating channel 201 is provided with a cylinder to prevent scratching the surface paper printing layer, and the cylinder There are a plurality of them, and air-permeable gaps 11 are formed between the drums. A heat source is provided on the roller to form a heating roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com