Anti-collision receiving device and anti-collision receiving method for threaded fasteners

A technology of threaded fasteners and receiving devices, applied in the directions of loading/unloading, trolley accessories, transportation and packaging, etc., can solve problems such as bumps, improve production efficiency, solve the quality problems of receiving bumps, and realize receiving protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand the present invention more clearly, but the protection scope of the present invention is not limited thereby.

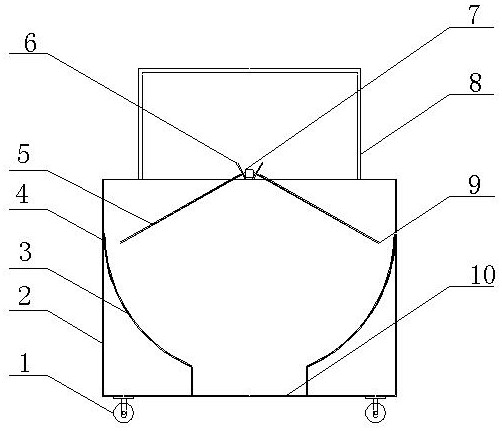

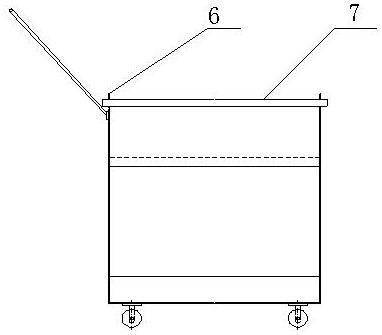

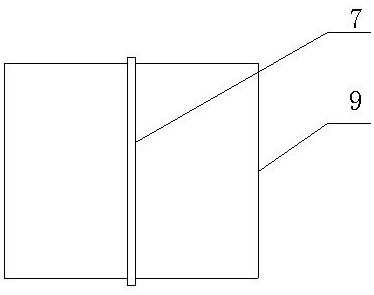

[0033] In view of the existing technical problems, the present invention proposes an anti-collision receiving device for threaded fasteners falling and recycling, as shown in the attached figure 1 to attach image 3 As shown, the anti-collision receiving device of the present invention includes: caster 1, trolley body 2, curved side plate 3, side plate buffer rubber 4, V-shaped baffle buffer rubber 5, V-shaped card slot 6, square steel 7. Car handrail 8, V-shaped baffle plate 9 and floor buffer rubber 10.

[0034]The trolley body 2 is used as the transfer body of materials (threaded fasteners), and the casters 1 are arranged on the bottom surface of the trolley body, preferably including four casters, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com