Wet blank transfer arm structure

A technology for transferring arms and wet embryos, which is applied in the direction of textiles and papermaking, paper machines, papermaking, etc., to achieve the effect of low manufacturing and maintenance costs and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

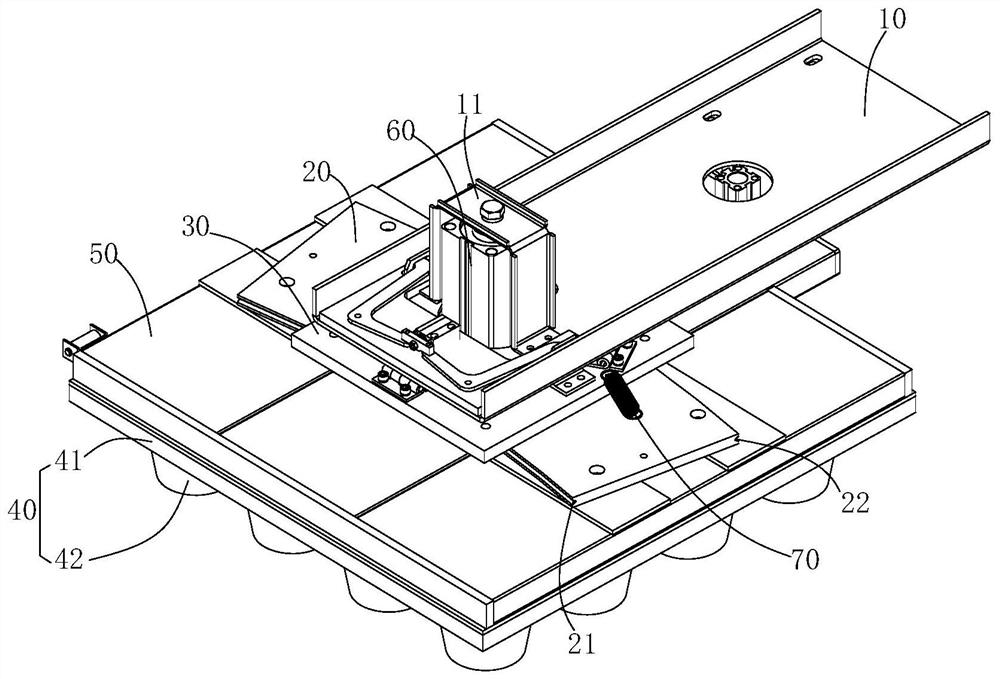

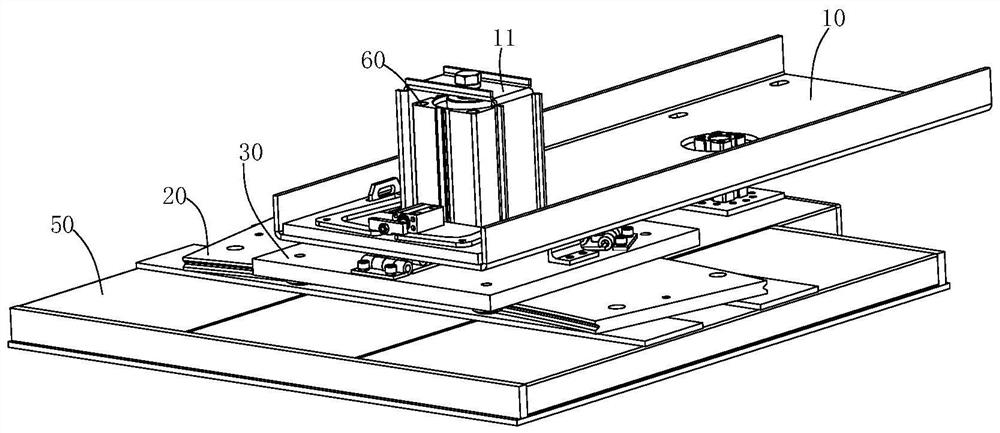

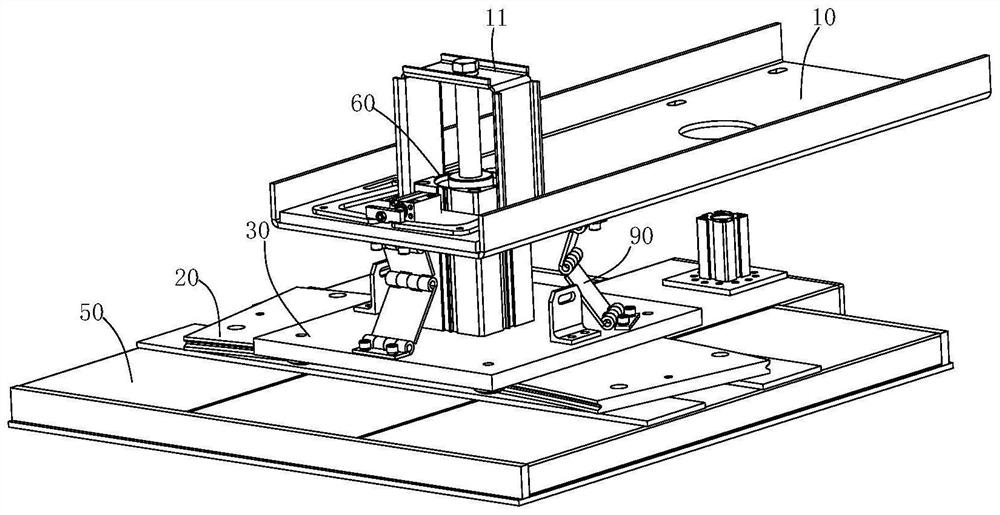

[0045] Please refer to Figure 1-10 , the present embodiment provides a wet embryo transfer arm structure, including a wet embryo transfer arm 10, an arc-shaped guide follower mechanism, a wet embryo adsorption mold 40, and a lifting drive mechanism;

[0046] The arc-shaped guide follower mechanism includes an arc-shaped guide plate 20 and a lifting mounting plate 30;

[0047] A side wall of the arc guide plate 20 is provided with a first arc track 21, and its opposite side wall is provided with a second arc track 22; the first arc track and the second arc track The track has the same center as the working circle of the rotary hot-pressing mold that cooperates with it;

[0048] The bottom surface of the lifting mounting plate 30 is provided with a first guide wheel 31 and a second guide wheel 32, and the first guide wheel and the second guide wheel cooperate with the first arc track and the second arc track respectively to form an arc. Shaped kinematic pairs; Specifically, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com