Vertical shaft wind turbine blade with variable trailing edge, and vertical shaft wind turbine

A technology of wind turbine blades and vertical shafts, which is applied in the direction of wind turbines at right angles to the wind direction, wind turbines, control of wind turbines, etc., can solve problems such as aerodynamic performance loss, structural damage, noise, etc., and achieve dynamic stall suppression and reduction Structural Vibration, Effect of High Lift Coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

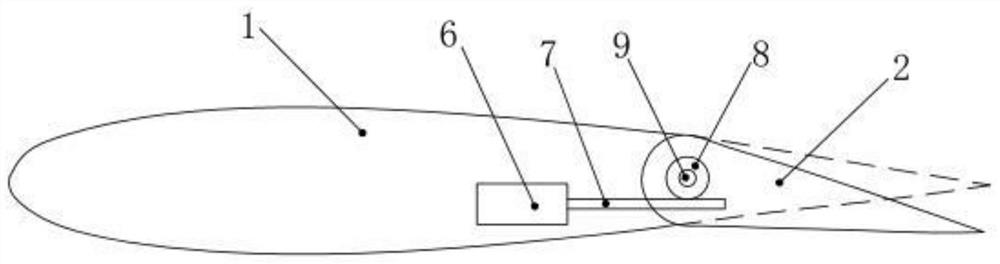

[0025] Such as figure 1 As shown, this embodiment provides a vertical axis wind turbine blade with a variable trailing edge, including a blade main body 1 and a variable trailing edge 2 hinged on the blade main body 1, when the central axis of the blade main body 1 and the variable rear edge When the central axis of the edge 2 is connected, the surface of the blade main body 1 and the surface of the variable trailing edge 2 are connected to form a smooth blade as a whole; the blade body 1 and the variable trailing edge 2 are both internal hollow closed structures, and The drive motor 6 used to drive the swing of the variable trailing edge 2 is fixedly installed in the blade main body 1 .

[0026] The rear end of the blade body 1 is concave, the front end of the variable trailing edge 2 is spherical, and the front end of the variable trailing edge 2 is installed in the rear end of the blade body 1, so that when the variable trailing edge 2 swings within a certain angle , the s...

Embodiment 2

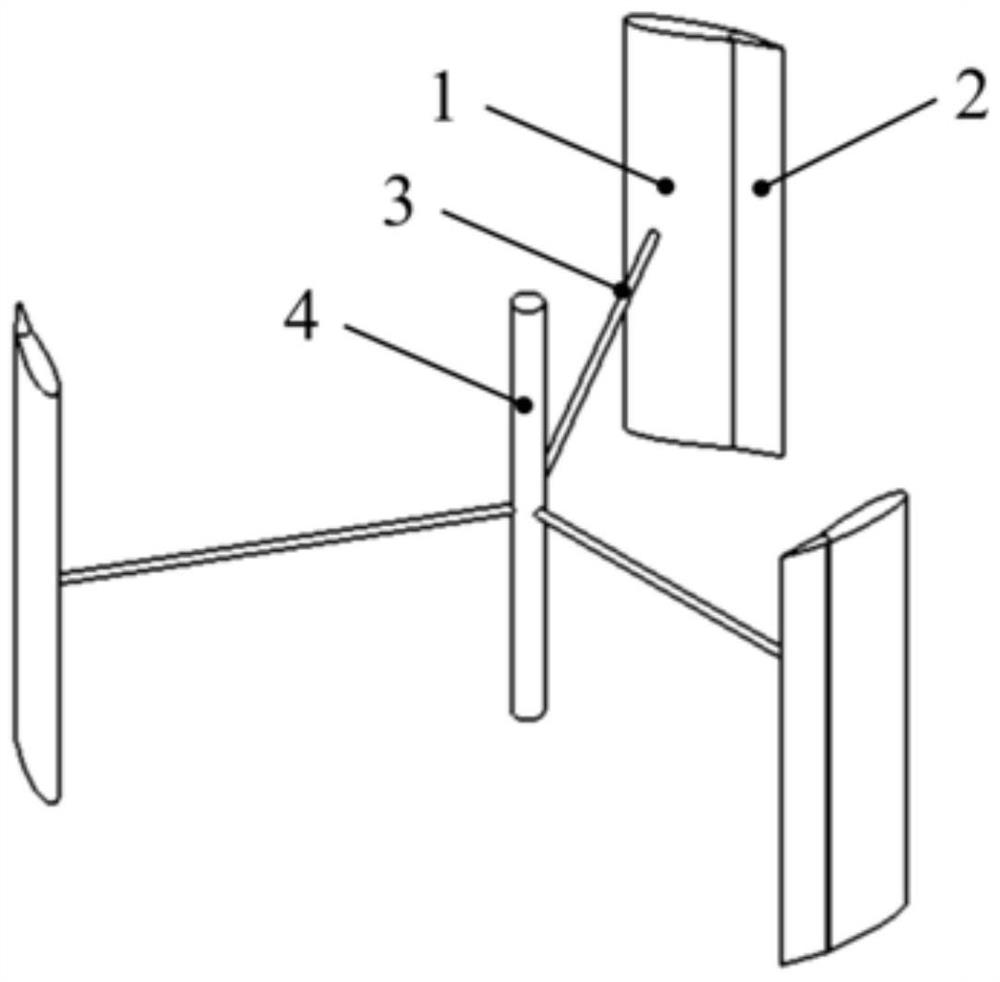

[0037] Such as figure 2 As shown, this embodiment 2 provides a vertical axis wind turbine on the basis of embodiment 1, including a rotating shaft 4 and a plurality of supports 3, and the plurality of supports 3 are evenly spaced along the circumferential direction of the rotating shaft 4, and The vertical-axis wind turbine blades in Embodiment 1 are installed on the extension ends of multiple brackets 3 , specifically, the blade main body 1 of the vertical-axis wind turbine blade with variable trailing edge 2 is fixedly installed on the extension ends of the brackets 3 .

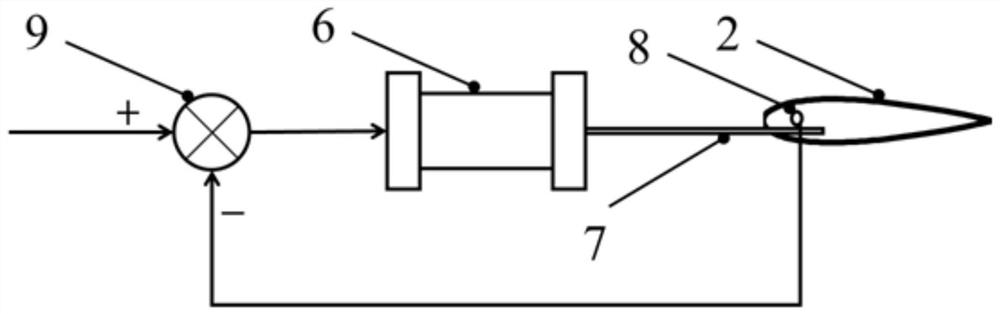

[0038] Such as image 3 As shown, the vertical axis wind turbine also includes a controller 9, which can be embedded in the rotating shaft 4 or in the bracket 3; the angle of attack sensor 5 is also installed on the bracket 3, specifically, the angle of attack sensor 5 Installed on the side of the bracket 3 close to the blade main body 1, the angle of attack sensor 5 is mainly used for real-time detection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com