Cutting path generation method based on greedy algorithm

A technology of cutting path and greedy algorithm, which is applied in the field of mechanical processing, can solve the problems of reducing processing efficiency, processing cutting trajectory with many empty strokes, and the algorithm is not simple, etc., to achieve the effect of improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing:

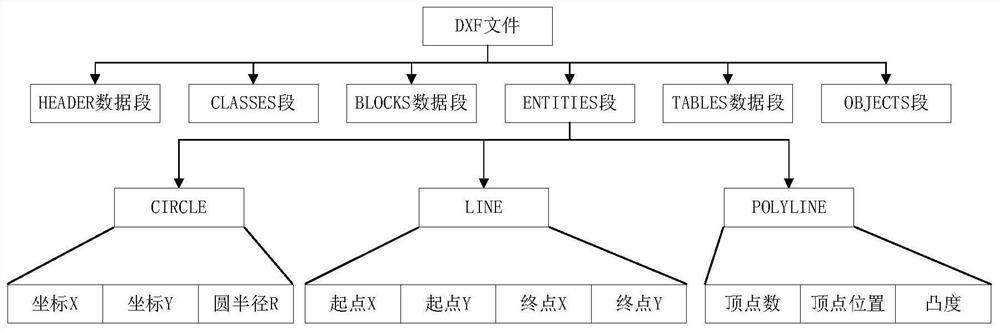

[0040] The workpiece drawing for laser cutting consists of DXF format, such as figure 1 The structure diagram of the workpiece drawing is shown. The workpiece drawing is composed of HEADER data segment, CLASSES data segment, TABLES data segment, BLOCKS data segment, ENTITIES data segment, OBJECTS data segment and file end data segment, and each data segment consists of multiple pairs Group code and group value composition.

[0041] The content represented by each data segment is different. The main graphic element data in the laser cutting workpiece drawing is in the ENTITIES data segment. This segment is the graphic element data entity segment, which contains all the graphic element information of the laser cutting workpiece drawing, including Types of primitives (lines, arcs, polylines), layer information, line types, colors and other information.

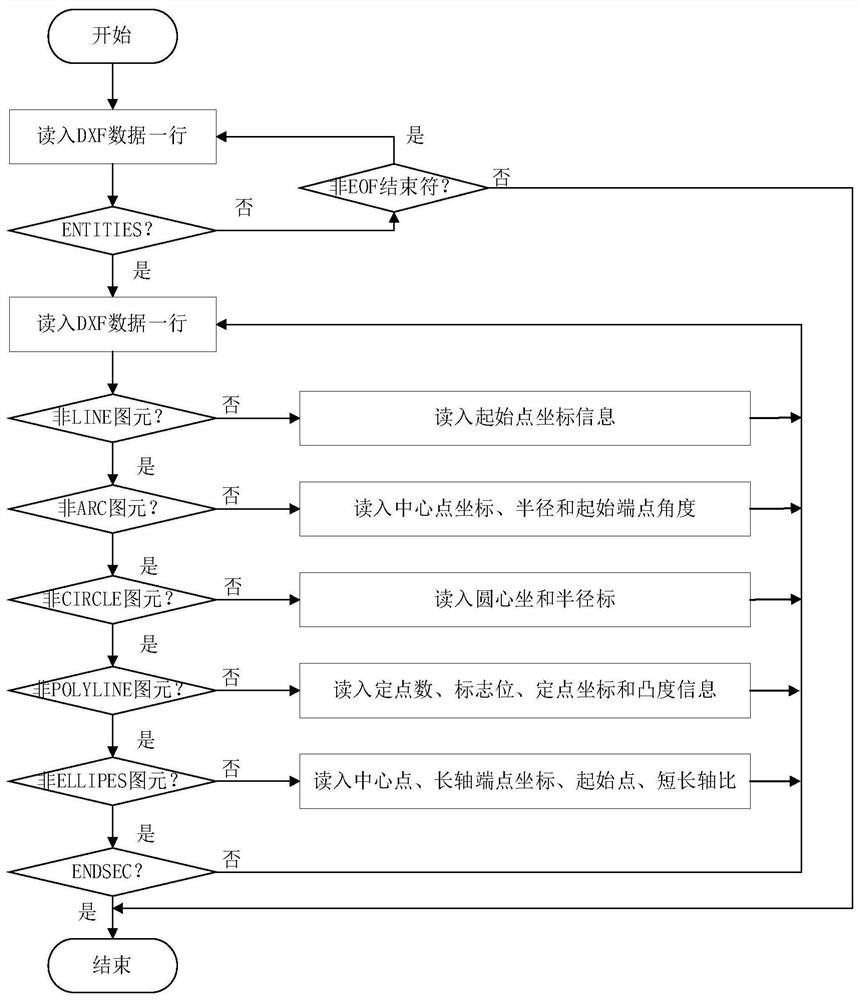

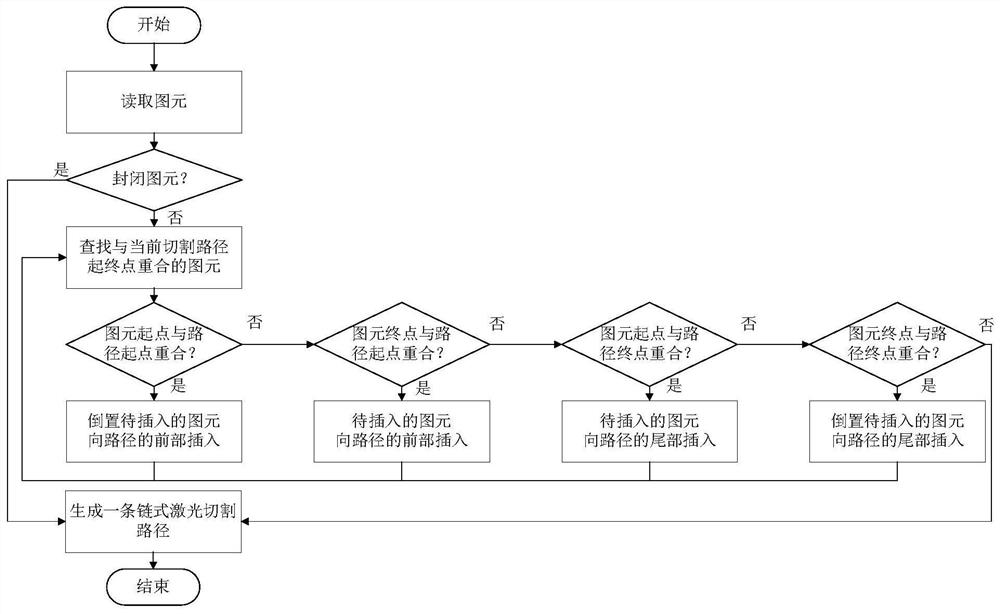

[0042] The key to da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com