Automatic picking, placing and conveying device for insect breeding and insect breeding system

A technology of automatic pick-and-place and transmission device, applied in transportation and packaging, conveyors, animal husbandry, etc., can solve the problems of uneven feeding, high labor intensity, and poor handling of breeding trays, so as to improve work efficiency and work efficiency. The effect of improving safety and diversifying farming methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

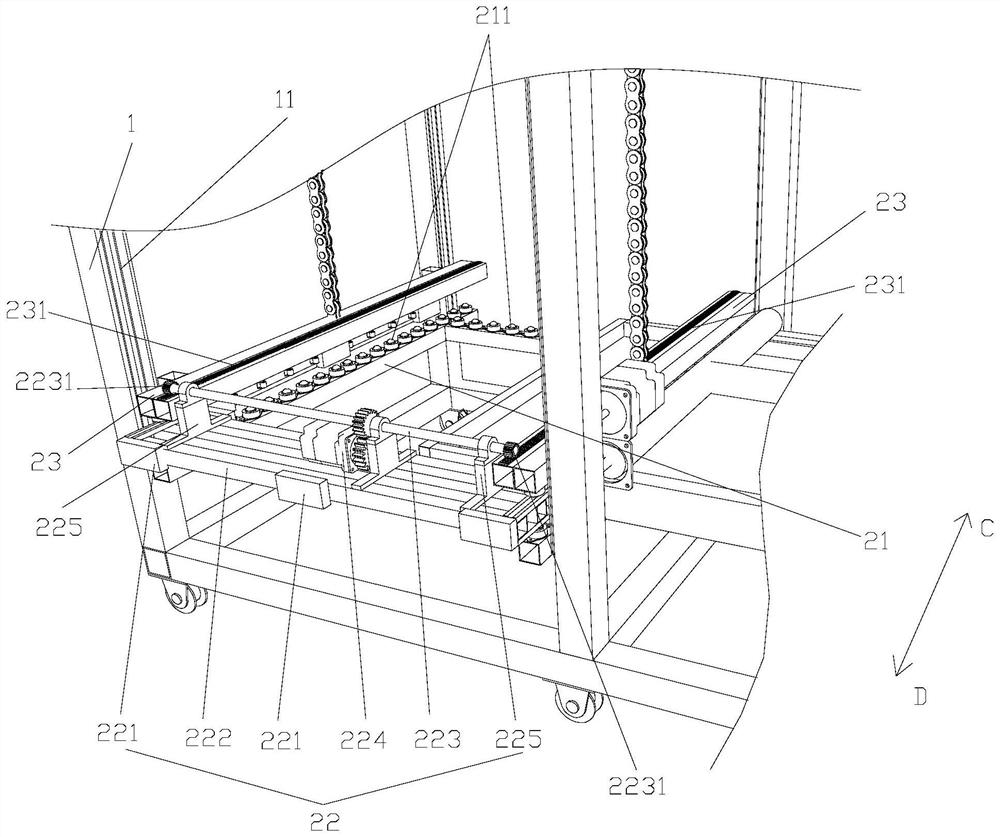

[0054] Inspired by the technical features and embodiments disclosed above, the present invention also proposes another implementation mode for the rack 1 and the disk fetching mechanism 2, specifically as follows:

[0055] Such as Figure 7 , Figure 8 As shown, the tray-taking mechanism 2 also includes a drawer-shaped installation box, and the front and rear ends of the installation box and the right side end are all provided with a transfer port, which is convenient for the breeding frame to enter and exit under the pushing of the push-pull assembly 22, and to facilitate The culture plate is translated to the right under the drive of the external drive mechanism, and the structural form of the bearing seat 21, the stop bar 23, and the push-pull assembly 22 are unchanged, and they are all located in the installation box. And just because there is an integrated installation box, the frame 1 is also different from the previous structural form. It only needs to be provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com