Necking-burnishing optimized composite device and process for titanium alloy bushing

A composite device, titanium alloy technology, applied in metal processing equipment, forging/pressing/hammer devices, manufacturing tools, etc., can solve the problems that the bushing is not suitable for spacecraft and the mechanical properties are greatly improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

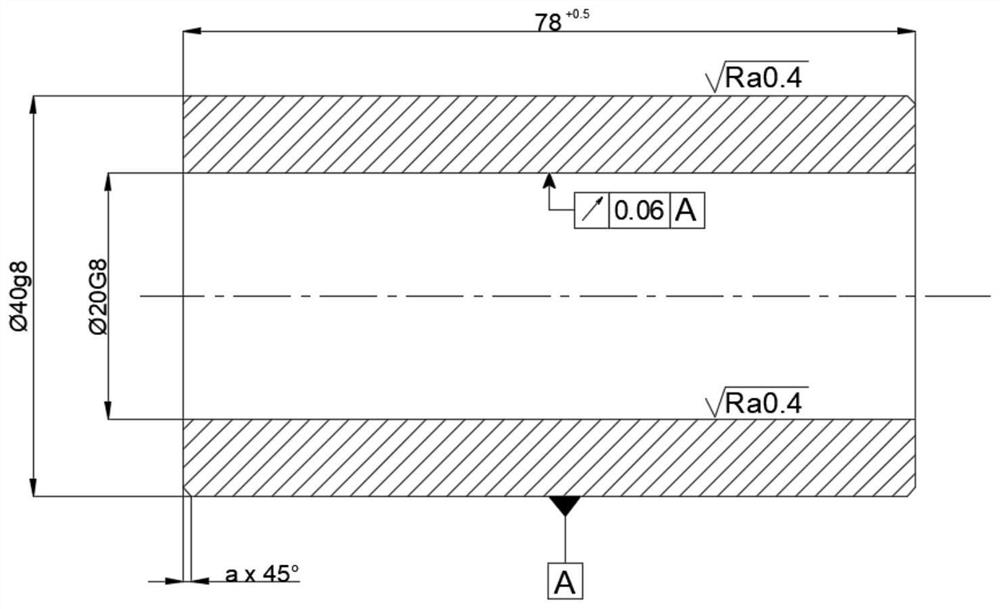

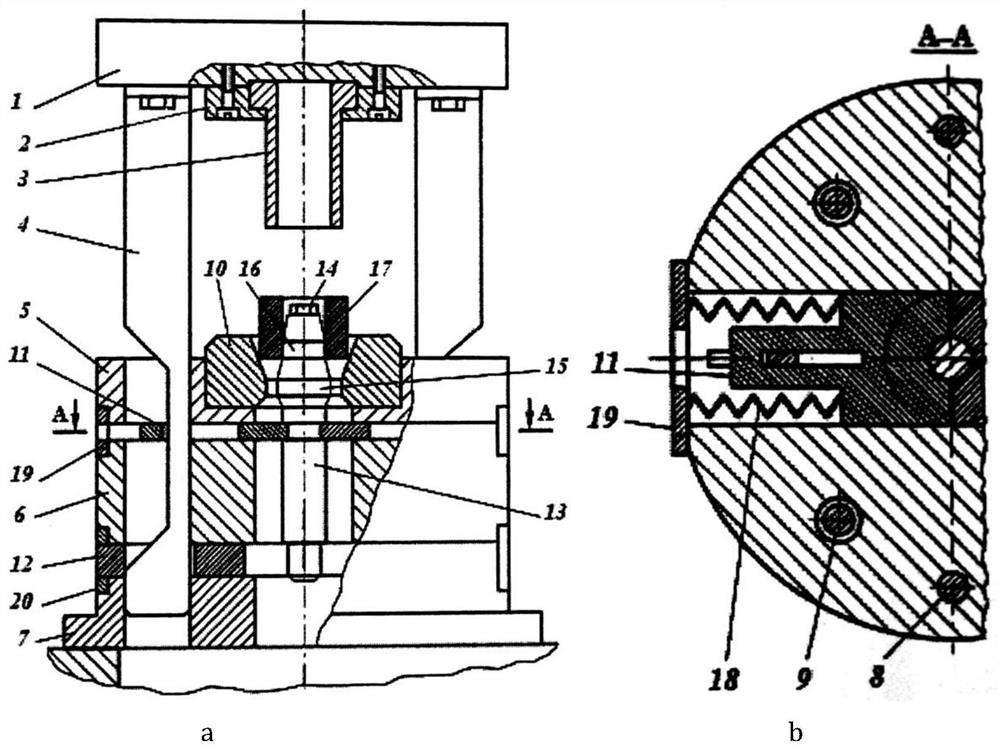

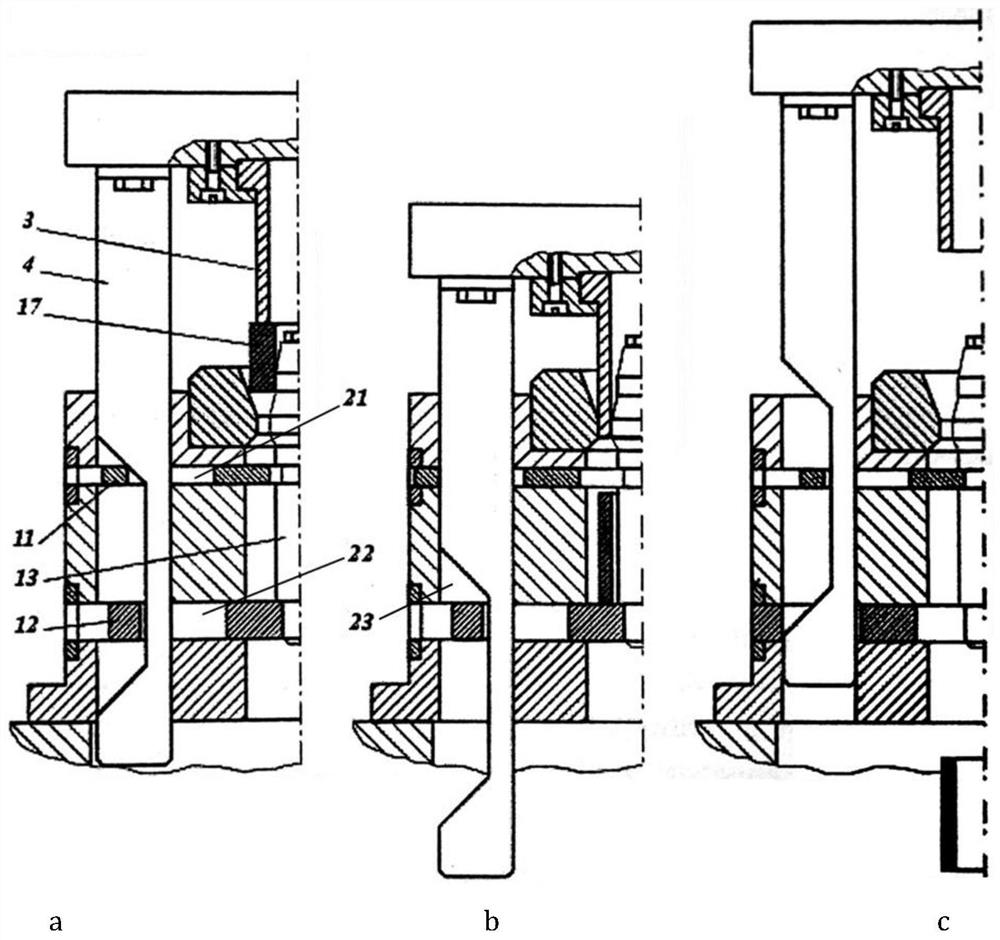

[0025] Such as figure 1 As shown, it is the transmission shaft bushing part used in aerospace engineering related to this embodiment. According to working conditions, the bushing should be corrosion-resistant in medium-temperature air medium. It was originally made of stainless steel 1Cr18Ni9Ti, but now it is made of industrial pure titanium TA1 for weight reduction. It is well known that the strength and wear resistance of this alloy cannot be improved by heat treatment. The strength of commercially pure titanium TA1 after annealing is not high. Therefore, the only way to improve its strength, hardness and wear resistance is cold plastic deformation. Considering the additional requirements of high precision for the manufacture of the bushing and low roughness of the cylindrical surface, the industrial manufacture with the combined necking-squeezing process is the most reasonable.

[0026] Therefore, in order to maximize the strength performance of the part, it is required ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com