Modular mold for gear precision forging forming and application method thereof

A combined mold and gear precision technology, which is applied in the field of forging and gear forging, can solve the problems of insufficient tooth profile filling, low tooth profile strength, and low processing efficiency, and achieve full tooth profile filling, high tooth profile strength, and high forging efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to clearly illustrate the technical characteristics of this solution, the following describes the solution through specific implementations.

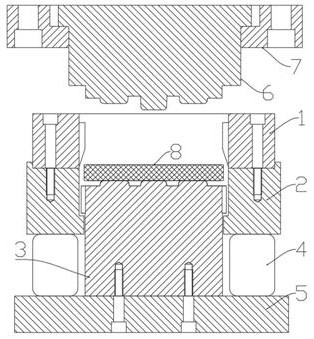

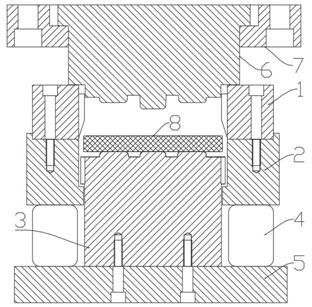

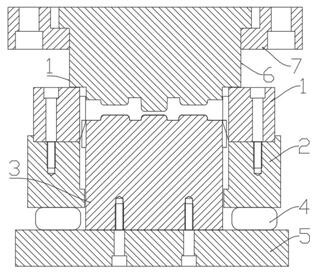

[0034] Such as Figure 1~9 As shown, a combined die for gear precision forging forming of the present invention includes a lower die 3 fixed on the base of the forging press and an upper die 6 fixedly connected to the lower end of the punch of the forging press.

[0035] The upper die 6 is cylindrical, and the top of the upper die is pressed against the lower end surface of the punch of the forging press. The upper die 6 is sleeved with an upper die fixing plate 7 which is fixed to the punch of the forging press by bolts. Then, the upper end of the upper mold 6 is provided with an upper mold fixing table located in the upper mold fixing plate 7. The upper mold fixing plate 7 is provided with a step hole, the upper mold 6 passes through the step hole, and the upper mold fixing table is located at the larger of the step hole. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com