Connecting method of steel-aluminum composite joints for naval ship

A steel-aluminum composite, joint connection technology, applied in welding/welding/cutting items, welding equipment, welding accessories, etc., can solve problems such as easy cracking at joints, reduce welding defects, stably control welding heat input, and improve effect of force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

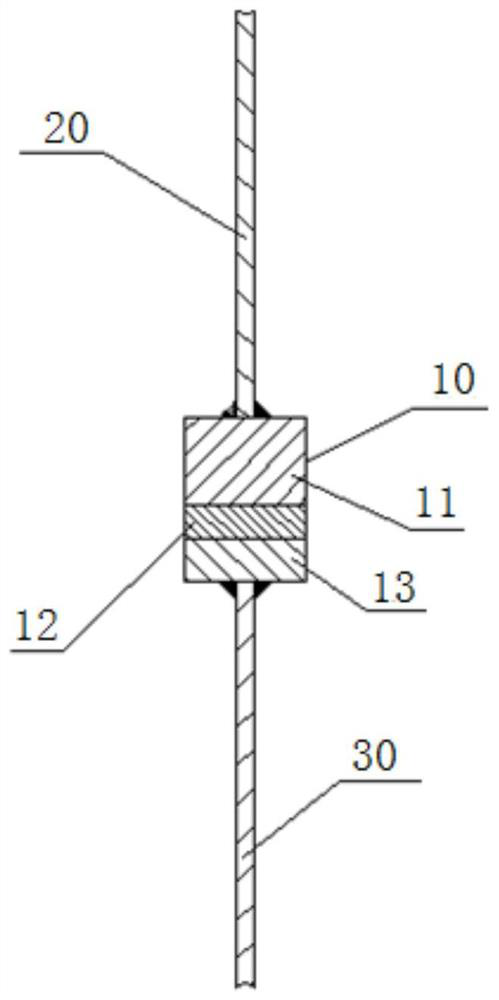

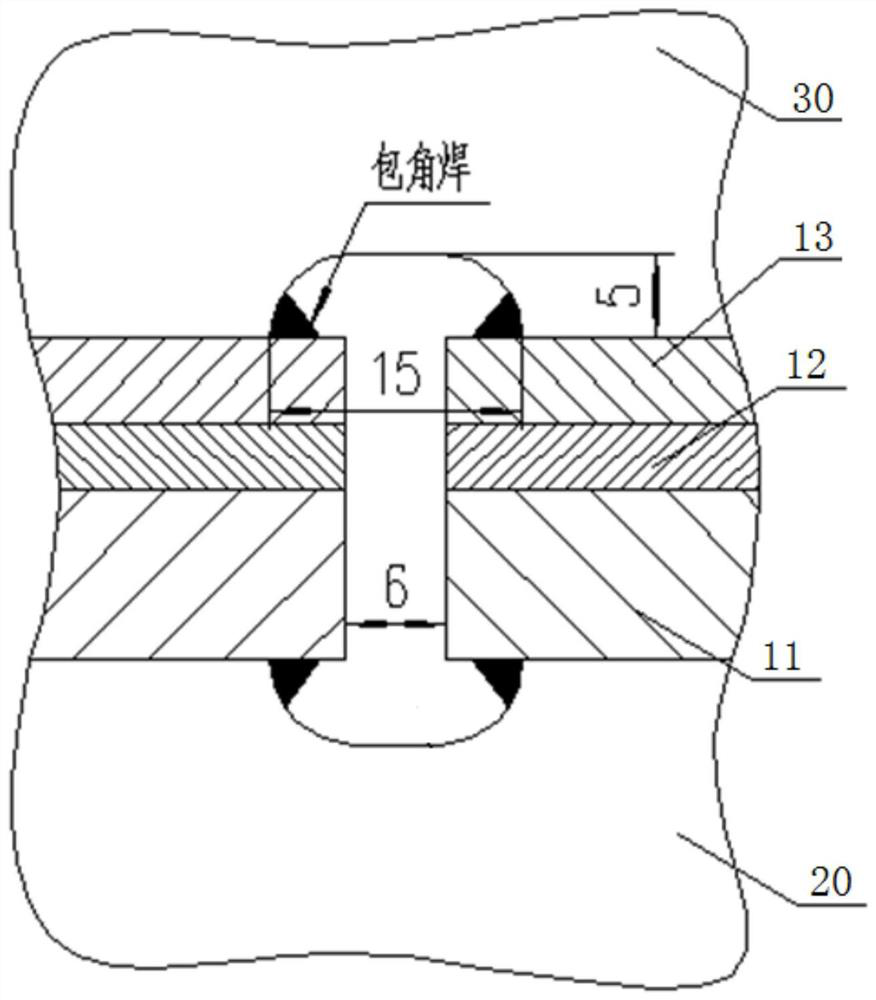

[0029] Such as figure 2 As shown, the butt connection method of steel-aluminum composite joints includes the following steps:

[0030] Step 1. Open semi-oblong holes with a size of 15mm×5mm and a chamfering radius of R5mm on the steel wall 20 and the aluminum alloy wall 30 respectively. The length of the opening can be adjusted according to the size of the weld leg and the butt gap, but it should be ensured that the distance between the end of the opening and the end wall of the weldment is greater than the size of the weld leg. This can ensure that the fillet welding at the end of the bulkhead is completed without damaging the boundary layer of the steel-aluminum composite joint, and avoiding the delamination of the boundary layer due to the welding effect.

[0031] Step 2. Set a gap of 6mm at the butt joint of the steel-aluminum composite joint 10, then weld the steel layer 11 of the steel-aluminum composite joint 10 to the steel wall 20, weld the aluminum alloy layer 13 t...

no. 2 example

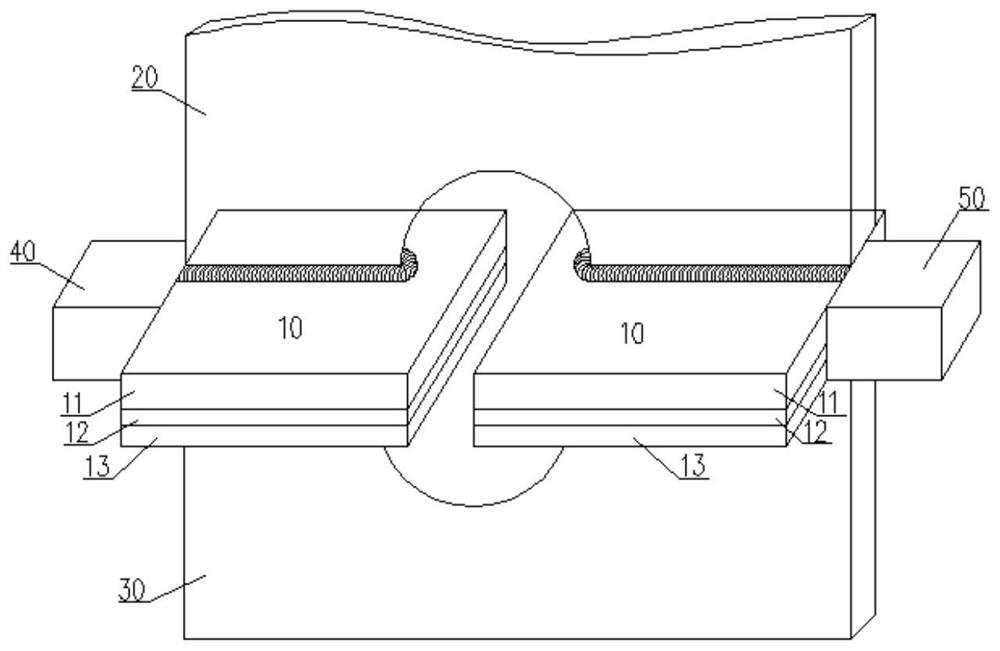

[0036] Such as Figure 4 As shown, the steel-aluminum composite joint 10 is connected by fillet connection, including the following steps:

[0037] Step 1. Cut two steel-aluminum composite joints 10 at angles of 45 degrees at the ends of the corner joints.

[0038] Step 2. Open fan-shaped openings with chamfering radius R10mm on the steel wall 20 and the aluminum alloy wall 30 respectively. The radius of the fan-shaped opening can be adjusted according to the size of the weld leg and the butt joint gap, but it should be ensured that the distance between the end of the opening and the end wall of the weldment is greater than the size of the weld leg.

[0039] Step 3. Set a gap of 6mm at the fillet connection of the steel-aluminum composite joint 10, then weld the steel layer 11 of the steel-aluminum composite joint 10 to the steel wall 20, weld the aluminum alloy layer 13 to the aluminum alloy wall 30, and not weld the gap. When welding, arc starting small blocks 40 and arc e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com