An intelligent industrial robot for 3D laser cutting

An industrial robot, three-dimensional laser technology, applied in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to achieve three-dimensional three-dimensional cutting, low work flexibility, etc., to improve staggered definition, high flexibility in use Sexual, convenient to use and observe the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

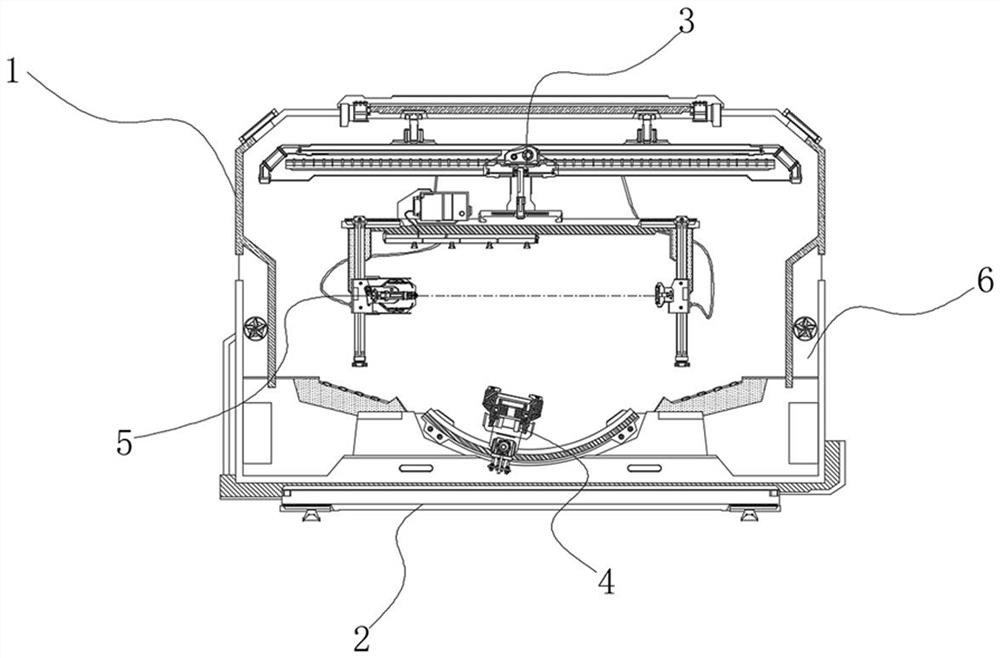

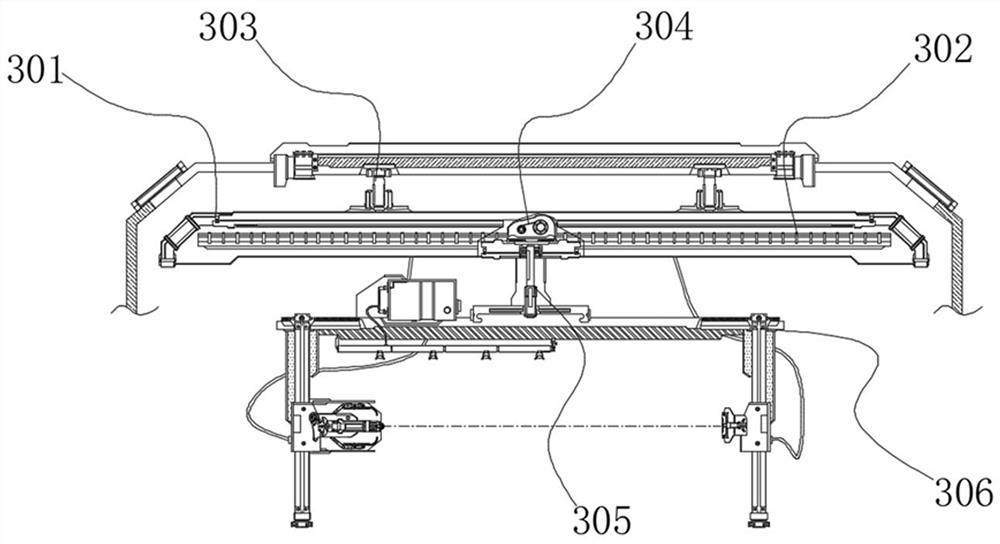

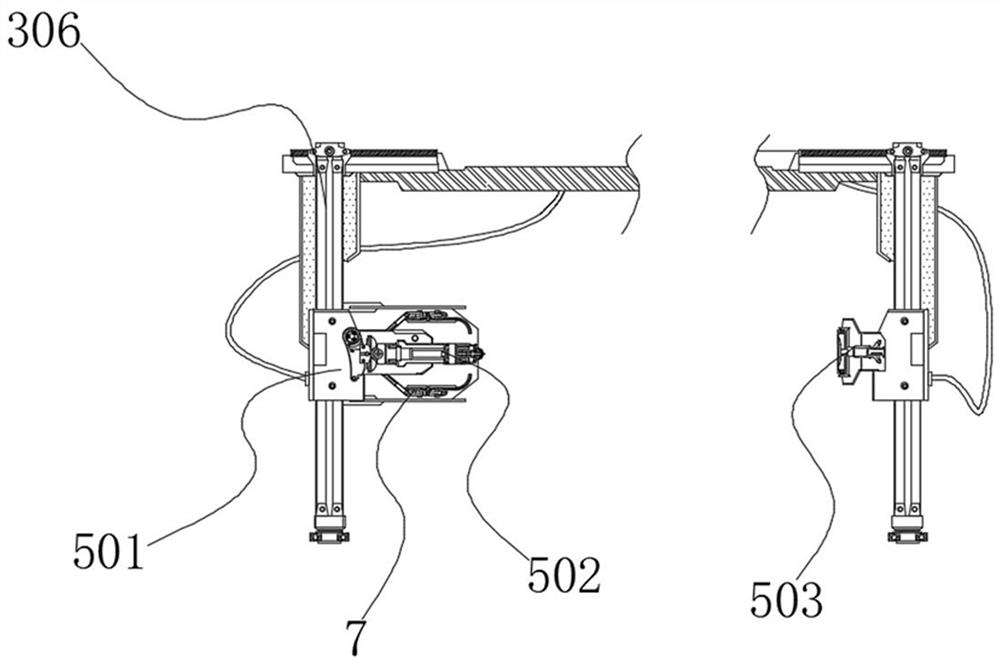

[0031] refer to figure 1, the present invention provides a technical solution: an intelligent industrial robot for three-dimensional laser cutting, which includes a device main body 1, a support base 2, a built-in transmission assembly 3, a laser cutting device 5, and a workpiece clamping assembly 4, wherein the The outer side of the end face of the device main body 1 is sealed with a working window, which puts the workpiece to be processed into or takes it out of the device main body 1, and the lower end face of the device main body 1 is embedded with a support base 2, and through The support base 2 is supported and fixed on the ground, and a workpiece clamping assembly 4 is installed at the center of the lower side of the device main body 1. The workpiece clamping assembly 4 effectively clamps and fixes the workpiece to be processed, and controls and adjusts the workpiece to be processed The inclination angle of the vertical plane makes the laser cutting device 5 perform tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com