Supersonic plasma spraying system and method for nickel base alloy coating

A supersonic plasma, nickel-based alloy technology, applied in the direction of metal material coating process, coating, melt spraying, etc., can solve the problem that the arc is not easy to change, the performance of nickel-based alloy coating is not good, and the flexibility during use is insufficient. and other problems to achieve the effect of improving the suitable area, facilitating the control and improving the performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

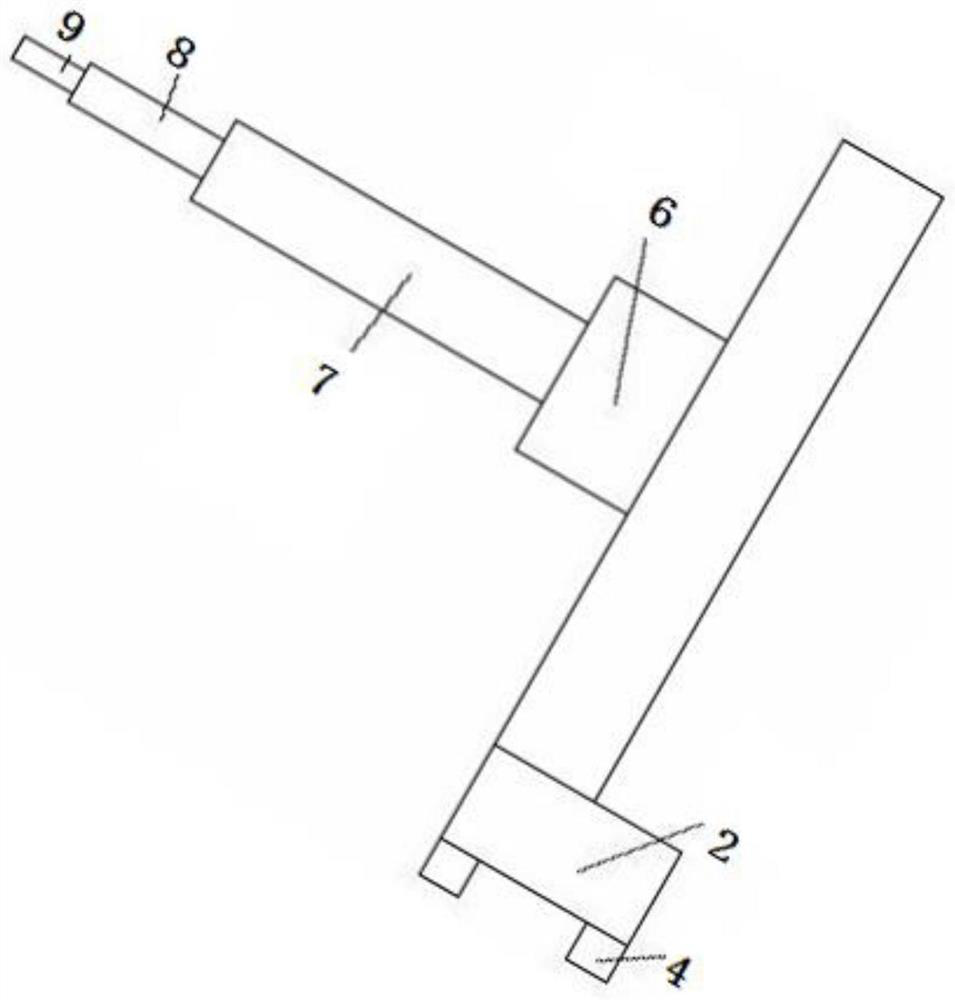

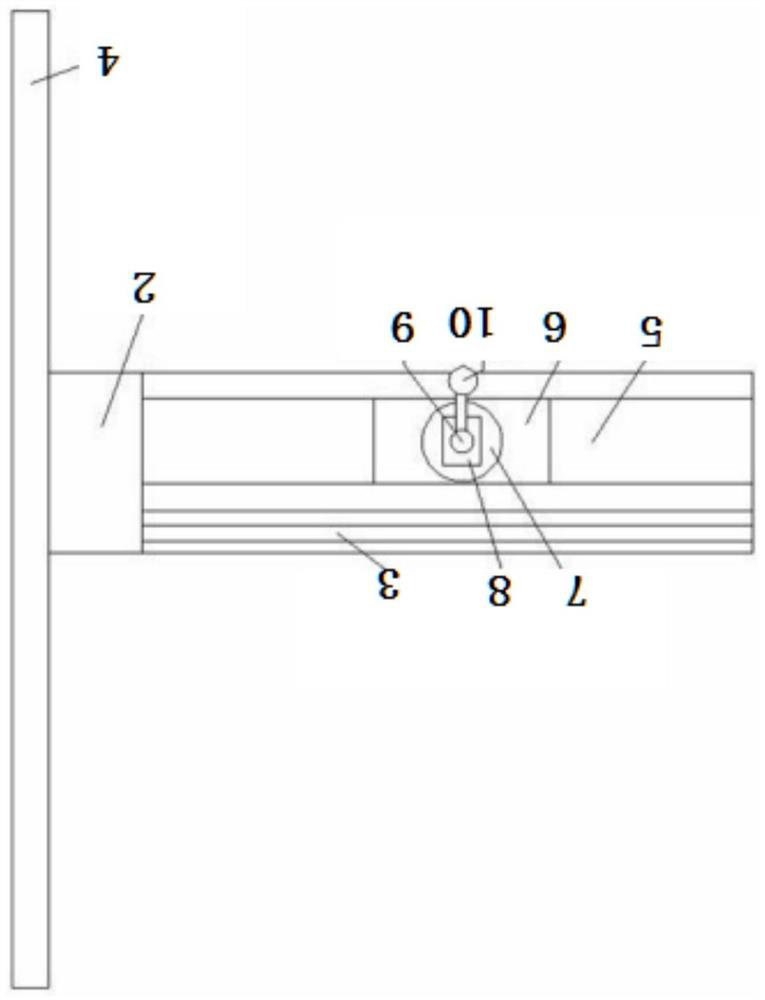

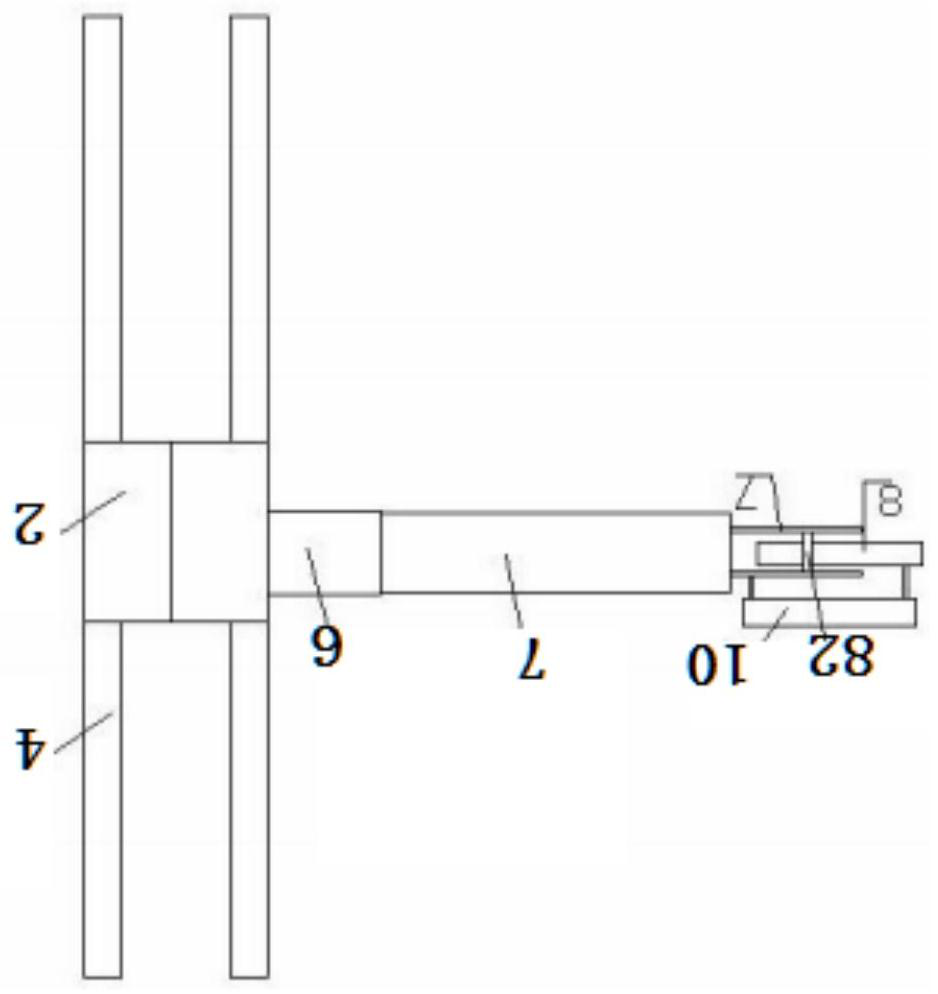

[0040] Such as Figure 1-Figure 3 As shown, the supersonic plasma spraying nickel-based alloy coating system includes:

[0041] A support platform 2, the support platform 2 is provided with a linear push rod, and the support platform 2 moves under the traction of the linear push rod;

[0042] A track 4 is provided at the bottom of the support platform 2, and the support platform 2 moves in the track 4 under the action of a linear push rod;

[0043] On the support platform 2, there is a strip-shaped guide opening 5 vertically, and a moving block 6 is movable in the strip-shaped guide opening 5;

[0044] The moving block 6 is provided with a rotary motor, which is beneficial to the control of the rotary motor, and the rotary motor is a speed-regulating motor; the output end of the rotary motor is connected with a linear piston 7, and the linear piston 7 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com