Unidirectional pure cotton flow-guide material, preparation method thereof, and product

A one-way flow, pure cotton technology, used in textiles, papermaking, textiles, bandages, etc., can solve the problem of large liquid re-infiltration of the surface layer, to ensure dryness, reduce liquid re-infiltration rate, and improve one-way flow effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

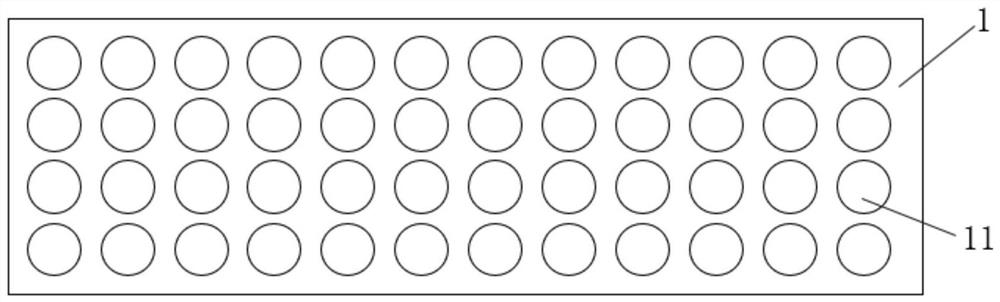

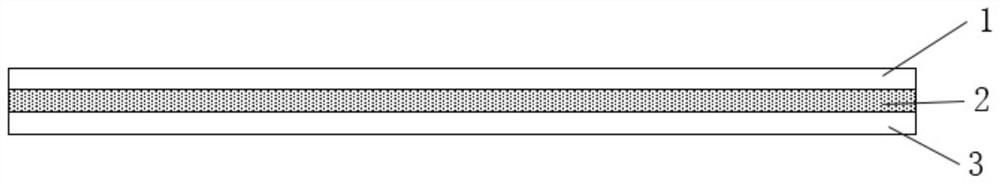

[0026] A method for preparing a pure cotton one-way flow guide material, comprising: a compounding step: compounding a hydrophilic cotton material 3 and a water-repellent cotton material 1 to obtain a pure cotton one-way flow guide material. The water-repellent cotton material 1 is covered on the hydrophilic cotton material 3 in the pure cotton one-way guide material, and part of the cotton fibers of the hydrophilic cotton material 3 extend into the cotton fibers of the water-repellent cotton material 1 to absorb moisture Quickly download. Wherein, the mass proportion of the hydrophilic cotton material 3 is smaller than that of the water-repellent cotton material 1 .

[0027] The preparation method of the above-mentioned pure cotton unidirectional flow-conducting material, because the hydrophilic cotton material 3 and the water-repellent cotton material 1 are combined into one structure, and the hydrophilic fibers and the water-repellent fibers are interlaced, can instantly fo...

Embodiment 1

[0042] A preparation method of pure cotton unidirectional flow guide material, comprising:

[0043] Unwinding step: unwinding operation of hydrophilic cotton spunlace nonwoven fabric and water repellent cotton spunlace nonwoven fabric, the unwinding speed is controlled at 35m / min.

[0044] Composite step: After the unwinding step, the hydrophilic cotton spunlace non-woven fabric and the water-repellent cotton spunlace nonwoven fabric are composited by high-pressure spunlace to obtain a pure cotton unidirectional flow guide material. The pressure of a single waterjet head is 90bar.

[0045] Among them, the mass ratio of hydrophilic cotton spunlace nonwoven fabric and water repellent cotton spunlace nonwoven fabric is 1:1.5.

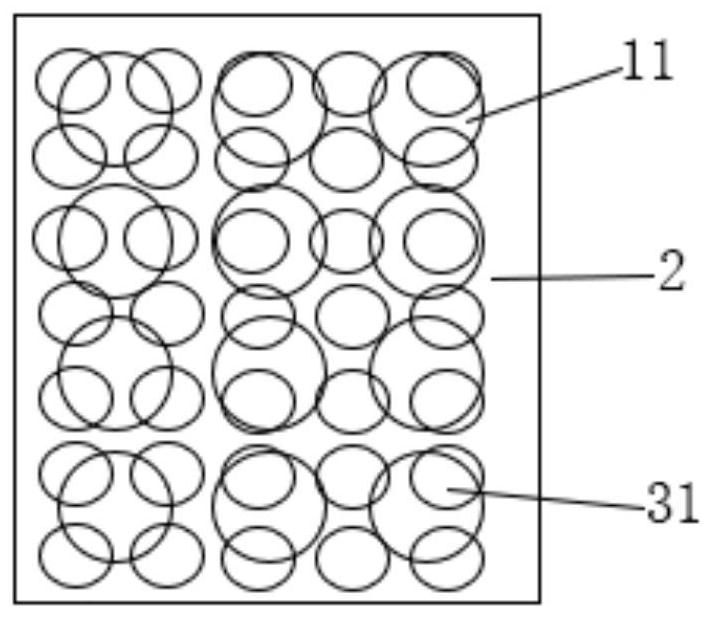

[0046] Both the hydrophilic cotton spunlace nonwoven fabric and the water repellent cotton spunlace nonwoven fabric have a mesh structure. The hydrophilic mesh 31 on the hydrophilic cotton spunlace non-woven fabric is smaller than the water-repellent mes...

Embodiment 2

[0049] A preparation method of pure cotton unidirectional flow guide material, comprising:

[0050] Unwinding step: Water-repellent cotton spunlace non-woven fabric is used for unwinding operation, and the unwinding speed is controlled at 35m / min.

[0051] Carding step: the hydrophilic cotton fiber is combed into a hydrophilic cotton web.

[0052] Composite step: after the unwinding operation, the water-repellent cotton spunlace non-woven fabric and the hydrophilic cotton net are composited by high-pressure spunlace to obtain a pure cotton one-way flow-conducting material. The pressure of a single hydrojet head is 70bar.

[0053] Among them, the mass ratio of hydrophilic cotton net and water-repellent cotton spunlace nonwoven fabric is 1:3.

[0054] Both the hydrophilic cotton net and the water-repellent cotton spunlace nonwoven fabric have a mesh structure. The hydrophilic mesh 31 on the hydrophilic cotton net is smaller than the water-repellent mesh 11 on the water-repell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com