Treatment agent for elastic fibers and elastic fibers

A technology of elastic fiber and treatment agent, which is applied in the field of elastic fiber and treatment agent for elastic fiber, can solve the problems such as difficult to unwind stably, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

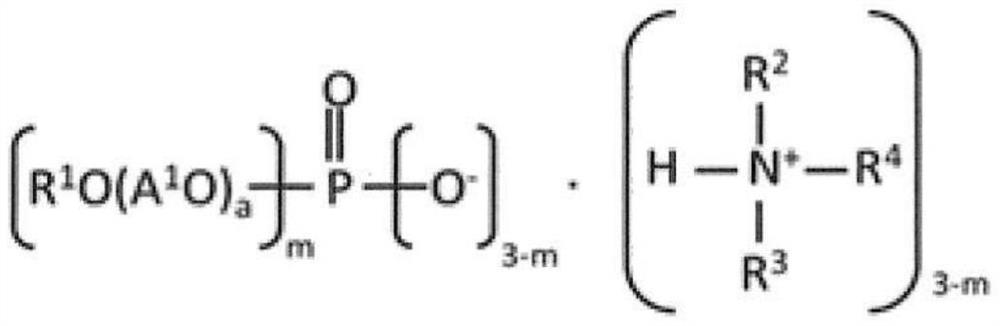

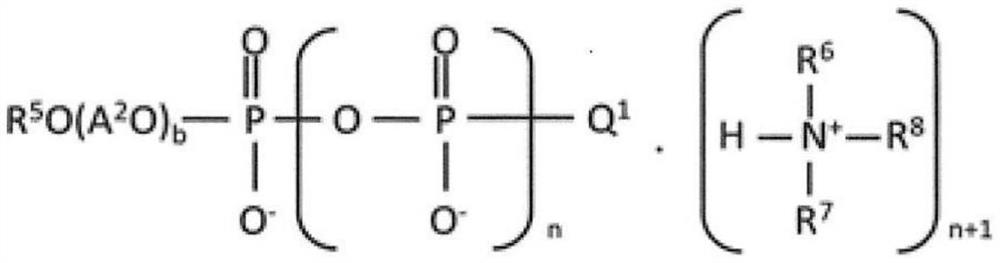

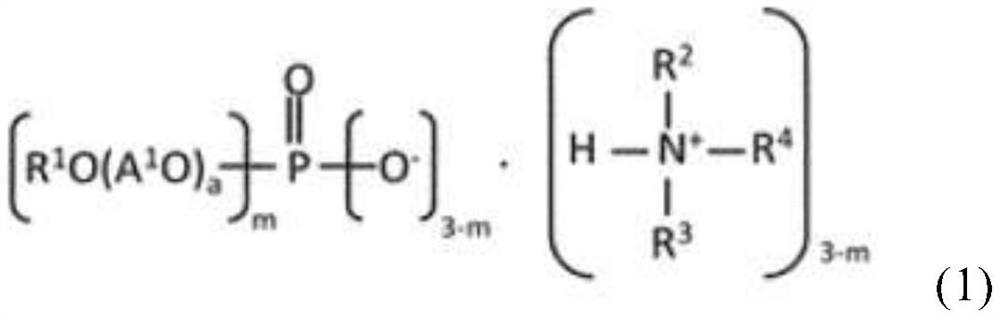

[0034] Next, the first embodiment of the treatment agent for elastic fibers (hereinafter referred to as treatment agent) for concretely realizing the present invention will be described. The treatment agent of this embodiment contains a basic component, an amine salt of an alkyl phosphate, and a predetermined|prescribed quaternary ammonium salt.

[0035] Examples of the base component used in the treatment agent of this embodiment include silicone oil, mineral oil, polyolefin, and ester oil. One type of base component may be used alone, or two or more types may be used in combination suitably. The base component is compounded in the treatment agent as a smoothing agent to impart smoothness to elastic fibers.

[0036] Specific examples of silicone oil are not particularly limited, and examples include dimethyl silicone, phenyl-modified silicone, amino-modified silicone, amide-modified silicone, polyether-modified silicone, amino-polyether-modified Silicone, alkyl modified sil...

no. 2 Embodiment approach

[0075] Next, a second embodiment of the elastic fiber for concretely realizing the present invention will be described. The treatment agent of the first embodiment adheres to the elastic fiber of the present embodiment. The amount of the treatment agent (excluding the solvent) according to the first embodiment is not particularly limited, but it is preferably deposited in a ratio of 0.1 to 10% by mass from the viewpoint of further enhancing the effect of the present invention.

[0076] Examples of elastic fibers are not particularly limited, and examples thereof include polyester-based elastic fibers, polyamide-based elastic fibers, polyolefin-based elastic fibers, and polyurethane-based elastic fibers. Among these, polyurethane-based elastic fibers are preferable. In this case, expression of the effects of the present invention can be further enhanced.

[0077] The method for producing elastic fibers according to this embodiment includes oiling elastic fibers with the treat...

Embodiment

[0085] Hereinafter, in order to demonstrate the structure and effect of this invention more concretely, an Example etc. are given, However, this invention is not limited to these Examples. In addition, in description of a following Example and a comparative example, a part means a mass part, and % means a mass %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com