Reinforced concrete with steel core connection nodes and connection methods for prefabricated beams and columns

A technology of reinforced concrete and connection nodes, which is applied in the processing of building materials, buildings, building types, etc., can solve the problems of complex support calculations of formwork, uneven force on connection nodes, and difficulty in ensuring construction accuracy, etc., to achieve The overall construction is convenient, the pouring compactness is improved, and the appearance is beautiful

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

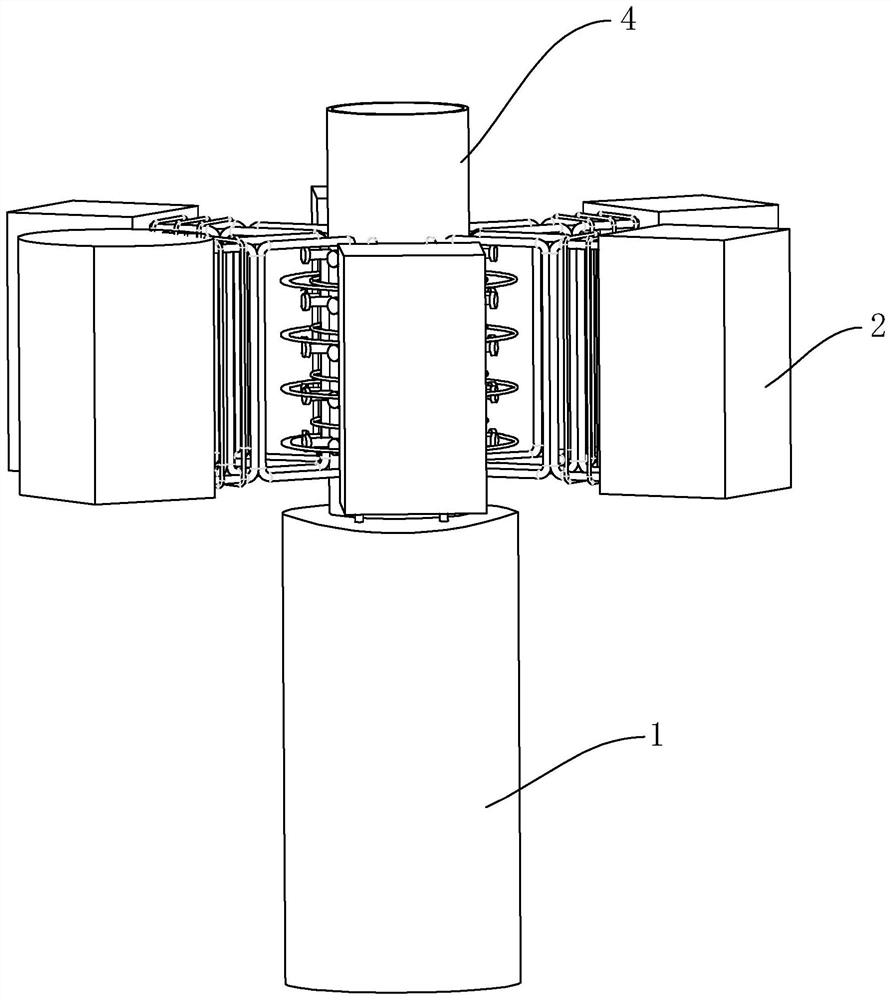

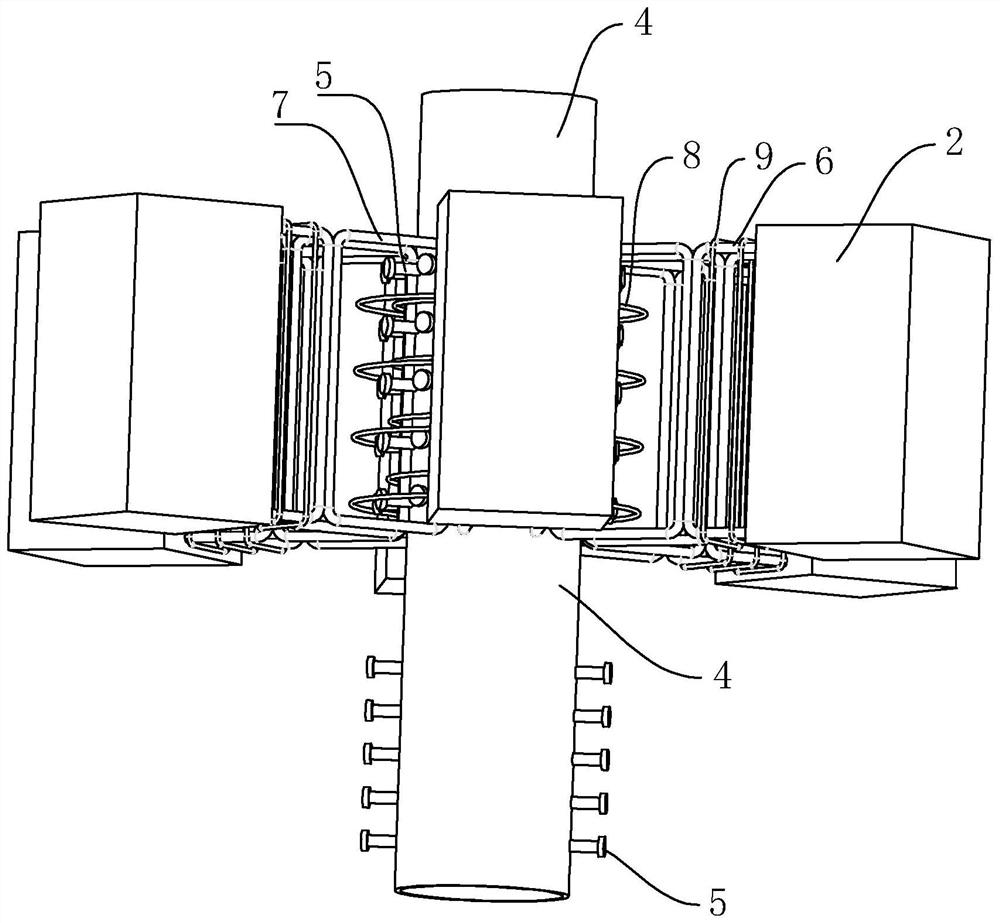

[0052] refer to figure 1 and figure 2 , which is a reinforced concrete connection node with steel pipe core for prefabricated beams and columns disclosed in the present invention, comprising a prefabricated column 1 and a plurality of prefabricated beams 2 arranged around the prefabricated column 1 .

[0053] The center of the prefabricated column 1 is preset with a steel pipe core 4, and the peripheral wall of the part of the steel pipe core 4 located in the prefabricated column 1 is provided with a number of studs 5. The studs 5 here are used for concrete pouring. Connection force of column 1. At the same time, a number of studs 5 can be selectively evenly distributed on the peripheral wall of the part outside the prefabricated column 1. On the one hand, the studs 5 can connect with other subsequent components, and on the other hand, they can connect with the future concrete. Strengthen the connection force between the steel pipe core 4 and the concrete.

[0054] The pre...

Embodiment 2

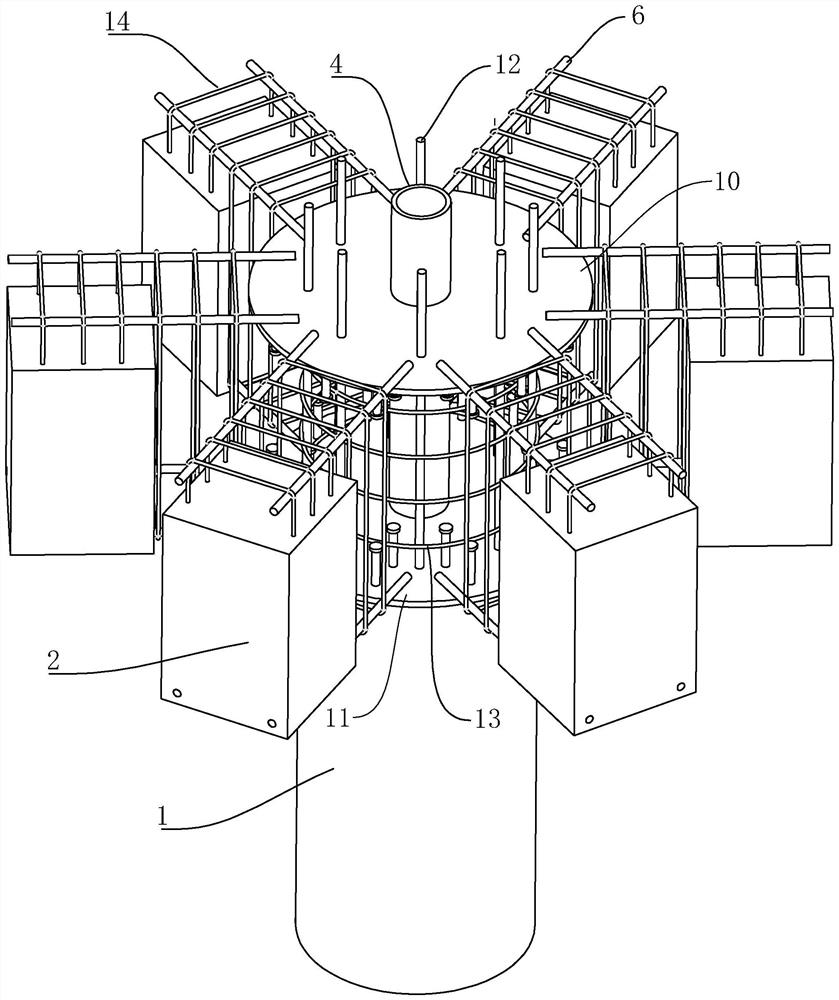

[0065] The difference from Example 1 is: refer to image 3 and Figure 4 , a bottom steel ring plate 11 and a top steel ring plate 10 are arranged on the peripheral wall of the part of the steel pipe core 4 outside the prefabricated column 1 in order from bottom to top, and there is a distance between the bottom steel ring plate 11 and the top steel ring plate 10. Generally, it is the height of the prefabricated beam 2 . The connecting reinforcing bars 6 are in the shape of "one", and several connecting reinforcing bars 6 are divided into beam bottom bars and beam top bars, one end of the beam bottom bars is located at the bottom of the prefabricated beam 2, the other end is welded with the bottom steel ring plate 11, and one end of the beam top bars is located in the prefabricated beam. 2 top, the other end is welded with the top steel ring plate 10.

[0066] The prefabricated column 1 is also provided with extended steel bars 12 . The extended steel bars 12 are located at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com