Drying oven for spinning

An oven and textile technology, applied in the textile field, can solve the problems of short drying path, long drying time, and small range, and achieve the effects of sufficient drying, high drying efficiency, and expanded drying range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

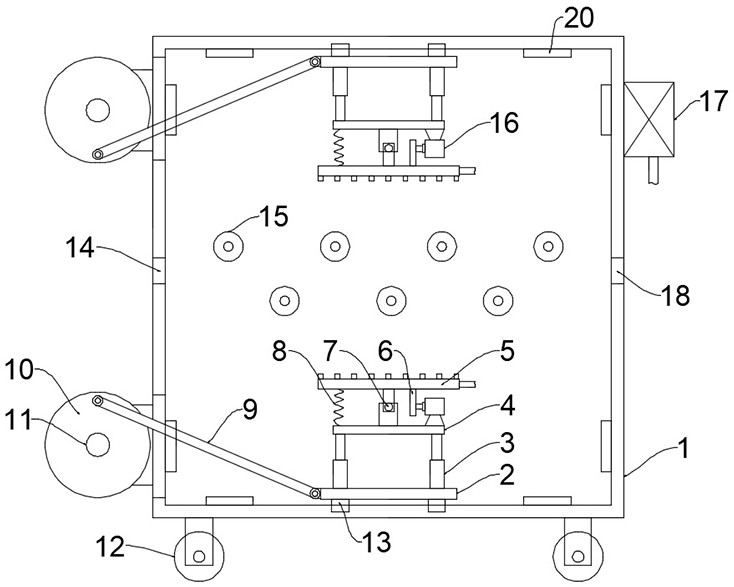

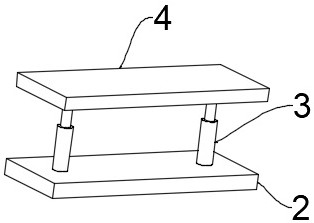

[0023] see Figure 1~2 , in the embodiment of the present invention, a textile oven includes a box body 1 and a drying unit, the bottom of the box body 1 is evenly and symmetrically fixed with rollers 12, and the rollers 12 are self-locking rollers, which facilitate the movement of the device. A box door is installed on the box body 1. In this embodiment, the box door is preferably installed on the box body 1 by hinges and hasps, and the symmetrical side walls of the box body 1 are respectively provided with openings for textile movement. Inlet 14 and outlet 18, further, in order to extend the drying path, a plurality of guide rollers 15 are installed in the box body 1 at the upper and lower sides of the inlet 14 and outlet 18, and the drying unit includes 1. The electric heating element 20 on the inner wall also includes an air-drying assembly located at the top and bottom of the inner cavity of the box body 1. The air-drying assembly includes a drying plate 5 and a driving m...

Embodiment 2

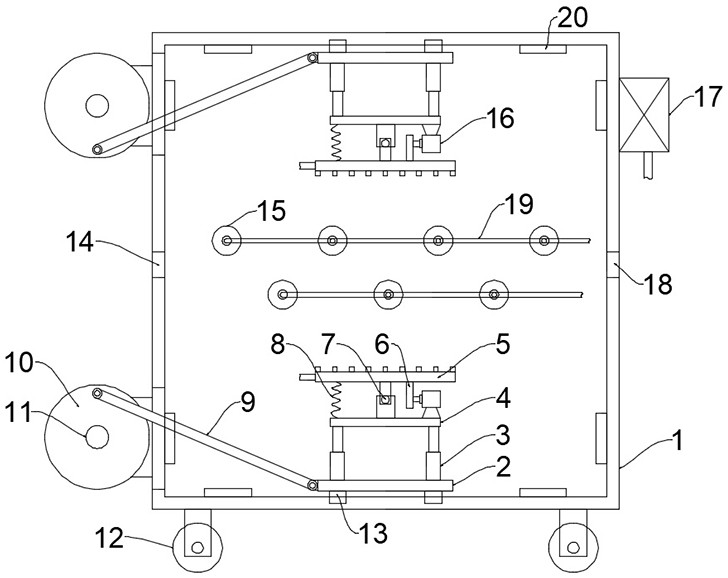

[0025] see image 3 The difference between the embodiment of the present invention and embodiment 1 is that the inside of the guide roller 15 is hollow and a plurality of spray holes are evenly opened on it, the guide roller 15 is connected with a second soft air pipe 19, and the second soft air pipe 19 The other end communicates with the air outlet of the hot air blower 17 to further dry the cloth with high drying efficiency.

[0026] The working principle of the present invention is: the cloth is passed through the guide roller 15 through the inlet 14 and finally passed through the outlet 18. When drying, the second motor 11 drives the turntable 10 to rotate, and the turntable 10 drives the first installation through the connecting rod 9. The reciprocating movement of the plate 2 can expand the drying range and improve the drying efficiency. The distance between the drying plate 5 and the cloth can be adjusted by extending or shortening the electric push rod 3. The first mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com