Super-flexible super-long-time fire-resistant mineral insulated cable and production process thereof

A kind of mineral insulated cable, special flexible technology, applied in the direction of insulated cables, insulated conductors, flexible cables, etc., can solve the problems of low fire resistance and poor bending performance of fireproof cables, and achieve remarkable fire resistance and best fire resistance Effective, disaster loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

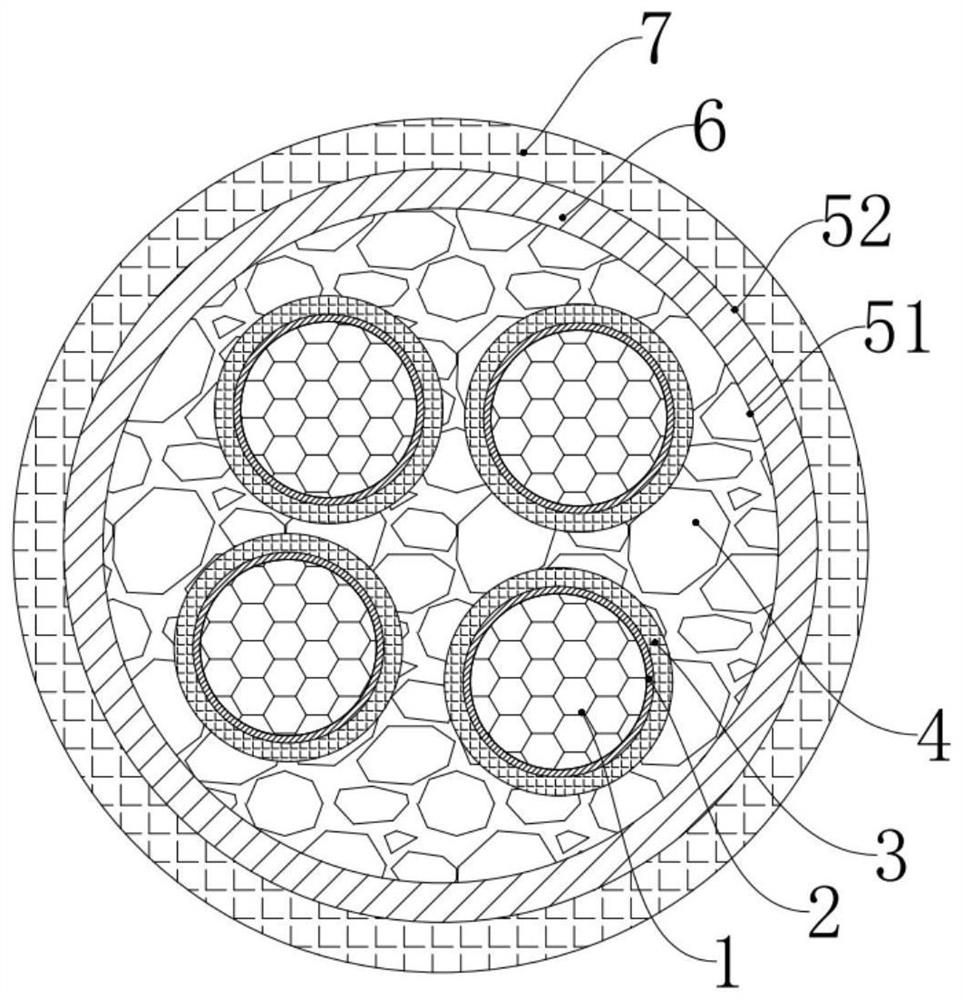

[0047] Such as figure 1 Shown: a super-flexible ultra-long-time fire-resistant mineral insulated cable, comprising: a core, a cable core, a fireproof layer 6, and an outer sheath 7; the core is twisted and filled with flame retardant 4 to form the cable core. The flame retardant 4 includes an alkali-free glass fiber rope in inorganic minerals. The cable core is wrapped with a fireproof layer 6 and an outer sheath 7 in sequence; the fireproof layer 6 is made of 1mm thick ceramicized polyolefin, and the fireproof layer 6 is closely attached to the inside and outside of the first glass fiber tape 51 and the second glass. Cellulose tape 52. The first glass fiber tape 51 and the second glass fiber tape 52 are 0.2×50 mm alkali-free glass fiber tapes. The outer sheath 7 is made of a 90°C flame-retardant, low-smoke, halogen-free sheath material, and the average extruded thickness of the outer sheath 7 is 1.8 mm.

[0048] The core includes a conductor 1, an insulating layer a2 wrapped a...

Embodiment 2

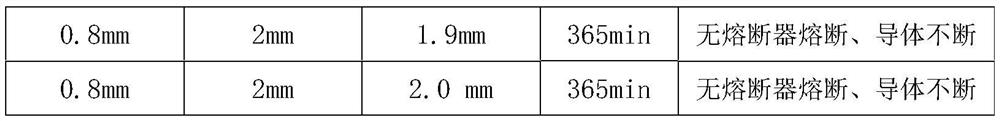

[0050] The difference between this embodiment and Embodiment 1 is that the fireproof layer 6 between the first glass fiber tape 51 and the second glass fiber tape 52 of 0.2×50 mm is extruded with a ceramicized polyolefin of 2 mm thickness; Example 1 is the same. Under the condition of the fire resistance temperature of 950-1000°C according to GB / T19216-2003, the cable of this embodiment has no fuse fusing and continuous conductors for 340 minutes, which exceeds the standard fire resistance requirement of 180 minutes. And according to BS 8491:2008, in the environment of fire supply + mechanical shock + water spray, the temperature of the fire supply is 950-1000 DEG C. The cable of the present invention has no fuse fusing, continuous conductor, and no cable breakdown. The minimum bending radius of this type of super-flexible ultra-long-time fire-resistant mineral insulated cable can reach 9.5 times the outer diameter of the cable.

Embodiment 3

[0052] The difference between this embodiment and embodiment 1 or 2 is that the fireproof layer 6 between the 0.2×50mm first glass fiber tape 51 and the second glass fiber tape 52 is extruded with 3mm thick ceramicized polyolefin; Others are the same as Embodiment 1 or 2. Under the condition of the fire resistance temperature of 950-1000°C according to GB / T19216-2003, the cable of this embodiment has no fuse fusing and continuous conductors for 360 minutes, which exceeds the standard fire resistance requirement of 180 minutes. And according to BS8491:2008, in the environment of fire supply + mechanical shock + water spray, the temperature of the fire supply is 950-1000°C, the cable of the present invention has no fuse fusing, continuous conductor, and no cable breakdown. The minimum bending radius of this type of super-flexible ultra-long-time fire-resistant mineral insulated cable can reach between 9.5 times and 10 times the outer diameter of the cable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com