Lightweight high-flexibility top-cover cross beam tailor-welding table

A highly flexible and lightweight technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as heavy switching equipment, heavy sunroof frame positioning fixture module 18, and a lot of manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

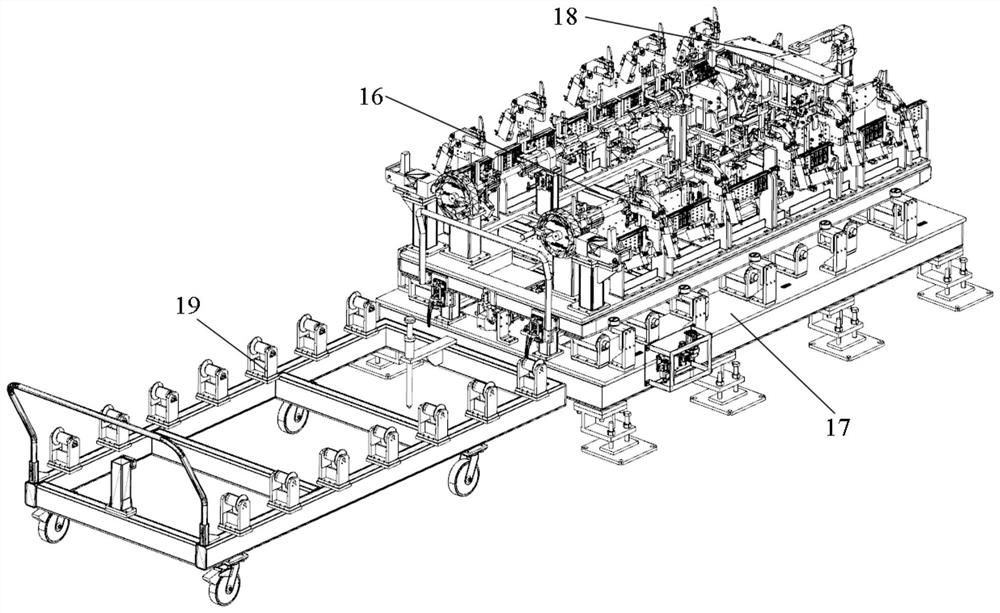

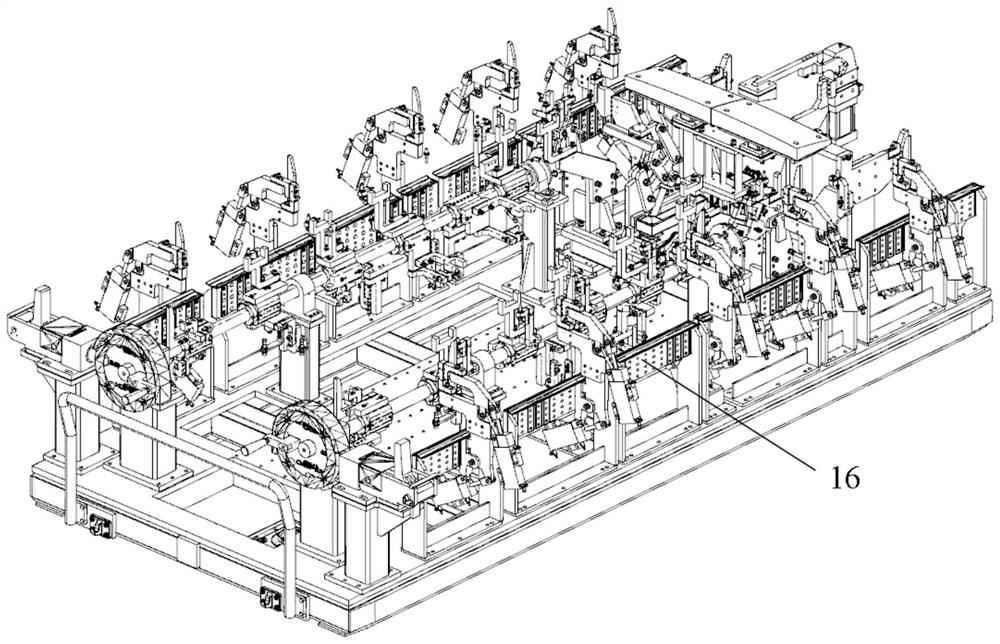

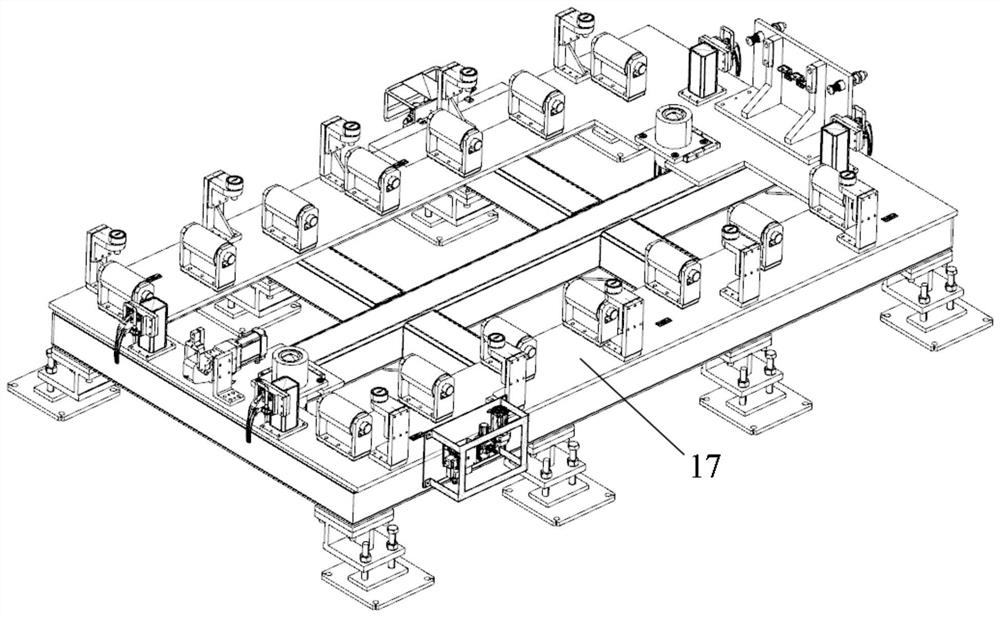

[0046] Combine below Figure 8 to Figure 15 , a light-weight and highly flexible roof beam tailor welding station of the present invention will be further described in detail. When describing directions (up, down, left, right, front, back, inside and outside) in the present invention, it is Figure 12 The structure shown in is a reference description, but the actual application direction of the present invention is not limited thereto. Wherein, the locking mechanism 7 for putting together the platform is on the front side, and the pushable flexible bottom plate 1 is on the rear side; the casters 12 are on the inner side, and the guide device 13 is on the outer side.

[0047] A light-weight and highly flexible roof beam tailor welding station of the present invention, please refer to Figure 8 to Figure 15 , including two sets of symmetrically arranged rotary switching devices 2, a set of sunroof outer panel pressing mechanisms for positioning and pressing the sunroof outer p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com