Wood board flattening device for woodwork carving machine and flattening method of wood board flattening device

A technology of engraving machine and wood board, which is applied in wood processing equipment, manufacturing tools, forming/shaping machines, etc., can solve the problems of the influence of grain groove accuracy, etc., and achieve the effect of improving engraving accuracy, reducing quantity, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

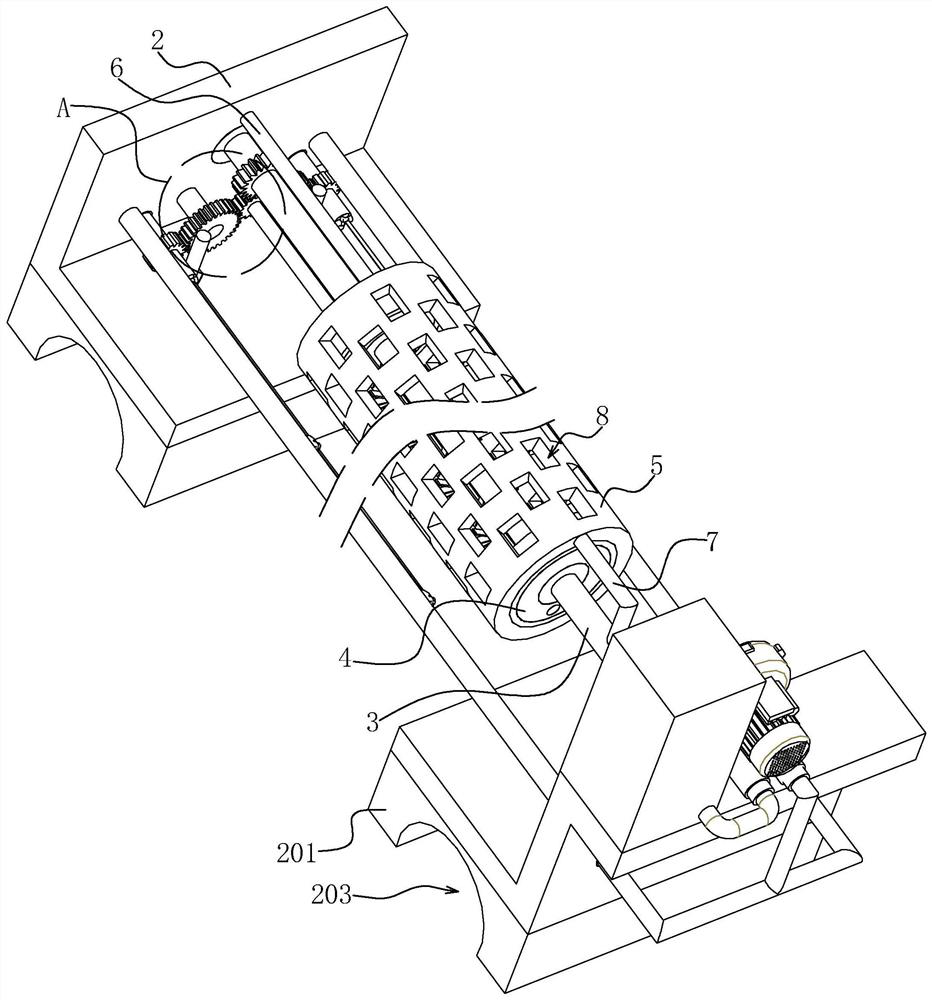

[0037] The following is attached Figure 1-7 The application is described in further detail.

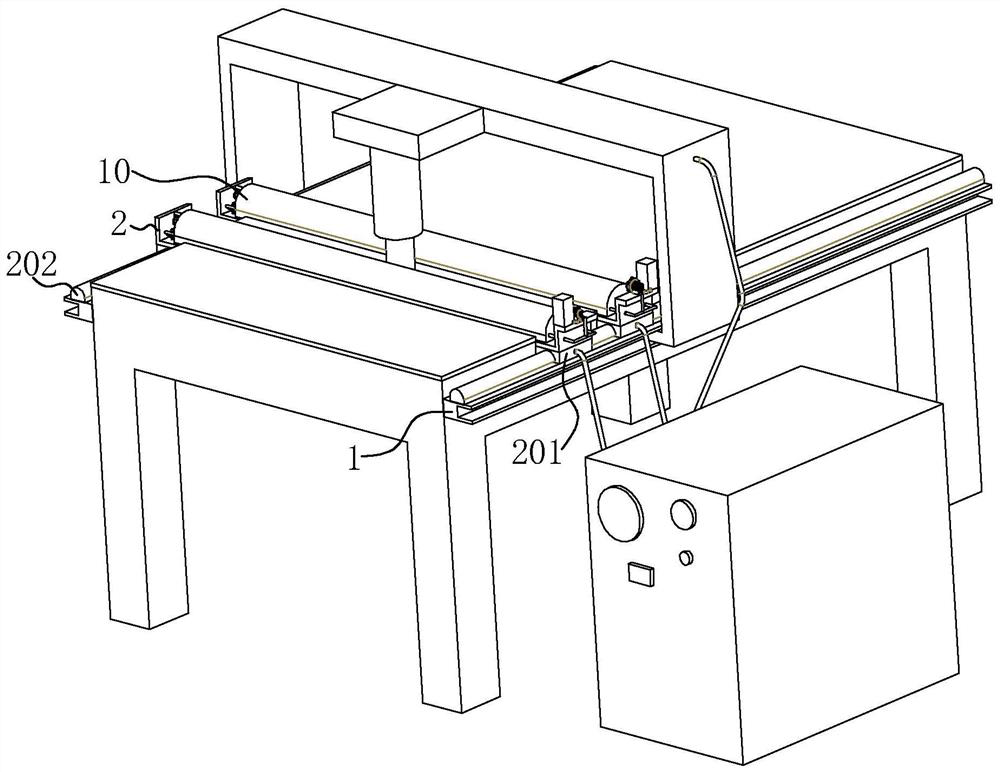

[0038] see figure 1 , which is a plank smoothing device for a woodworking engraving machine disclosed in the present application, includes sliding seats 1 fixedly connected to both sides of the workbench.

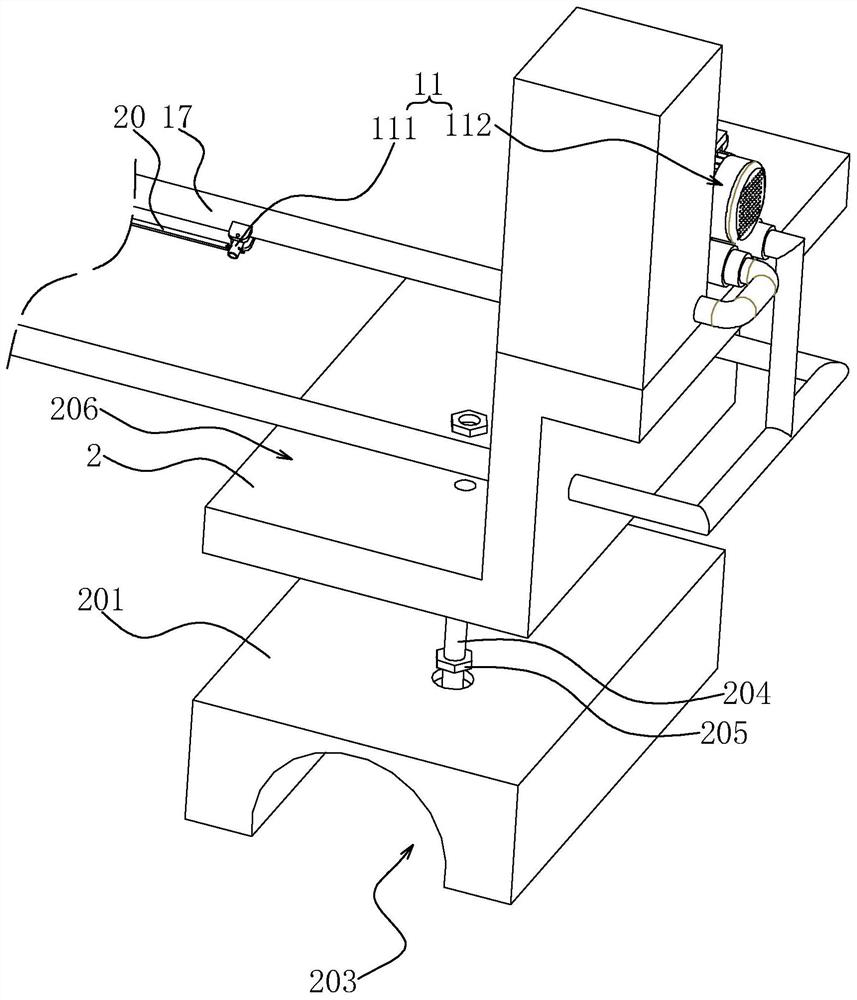

[0039] see figure 1 and figure 2 , the top of the sliding seat 1 is provided with the mounting seat 2, the bottom of the mounting seat 2 is provided with a slide plate 201, the bottom of the slide plate 201 is provided with a chute 203, the top of the sliding seat 1 is fixed with a slide bar 202, and the slide bar 202 is slidably connected to the chute 203, so that The mounting base 2 slides on the top of the sliding base 1 . When in use, the mounting base 2 is controlled by the engraving machine, so that the movement of the mounting base 2 can match the motion state of the milling cutter of the engraving machine.

[0040] see figure 1 and figure 2, the top of the slide p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com