Multifunctional hydraulic hoisting rescue equipment

A multi-functional, hydraulic technology, applied in the direction of equipment fixed on the vehicle, railway car body parts, transportation and packaging, etc., can solve the problems of equipment cannot be laid, affect rescue, complicated installation process, etc., to ensure operational safety and safety. Reliability, simple and fast installation, convenient and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

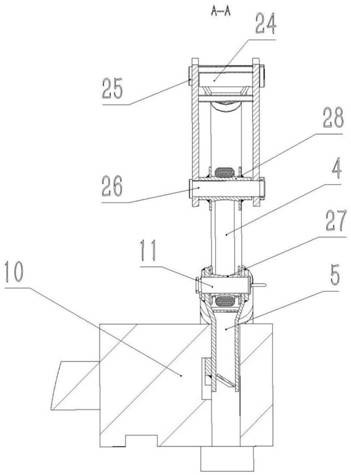

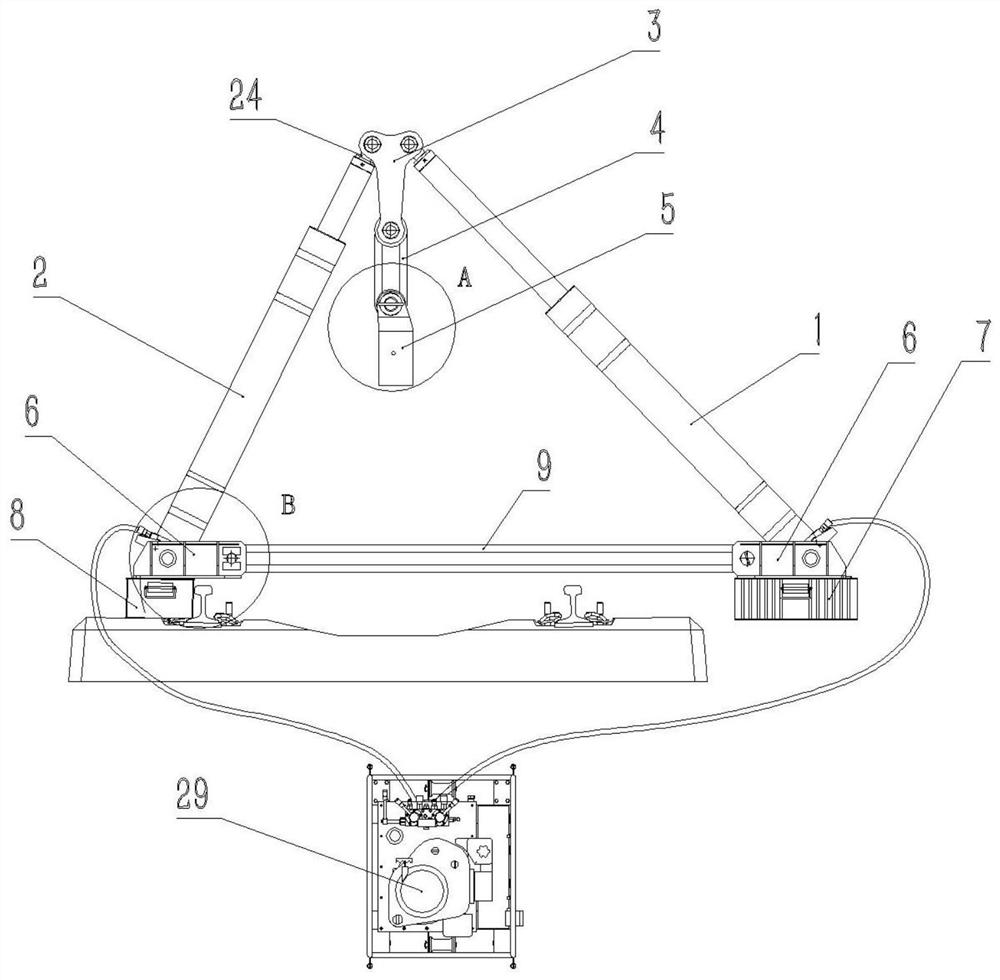

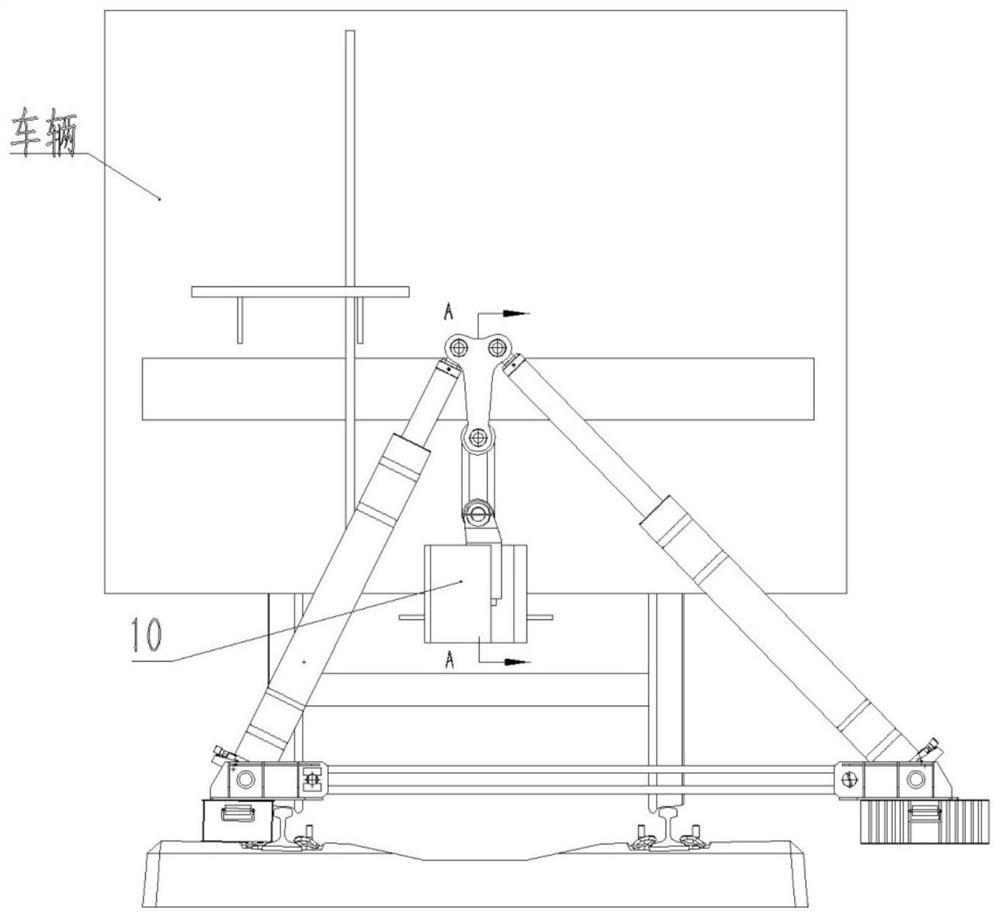

[0036] Such as figure 2As shown, the hook device 5 is installed, and the hook device 5 can be directly slid sideways into the coupler body 10 during installation, and the side of the hook device 5 containing the iron stopper 12 is inserted into the square hole in the coupler body 10 That's it. Install the equipment according to the off-line direction of the car body. If the car body is off-line to the right when facing the direction of the coupler, lay the base fastener beam 8 on the outside of the left rail, and fix the oil cylinder base 6 above the base fastener beam 8. The base support pad 7 is laid on the outside of the side rail, and the oil cylinder base 6 is fixedly installed above the base support pad 7. The two oil cylinder bases 6 are connected by the base connecting rope 9 and the base pin 14, and the proper position is adjusted. The base pin 14 Rotate 90° after piercing into the base of the oil cylinder to prevent it from coming out. Hinge the two single-stage o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com