Bilge structure and bottoming barge

A technology of barge and bottom, which is applied in the construction of barges/flats, hulls, ships, etc. It can solve the problem of high cost and achieve the effect of low transformation cost, increased water depth and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

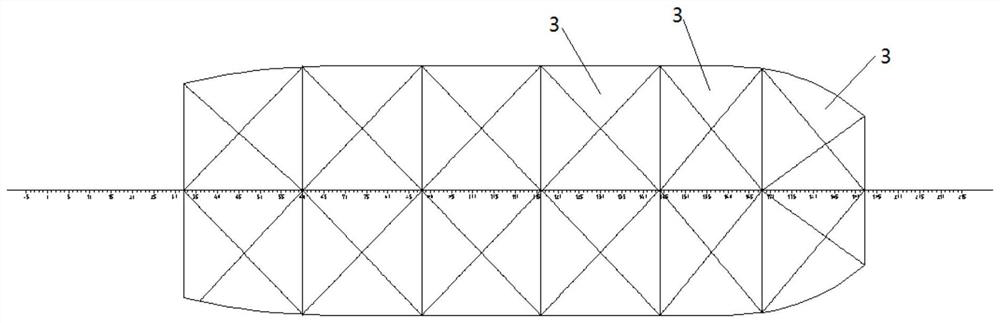

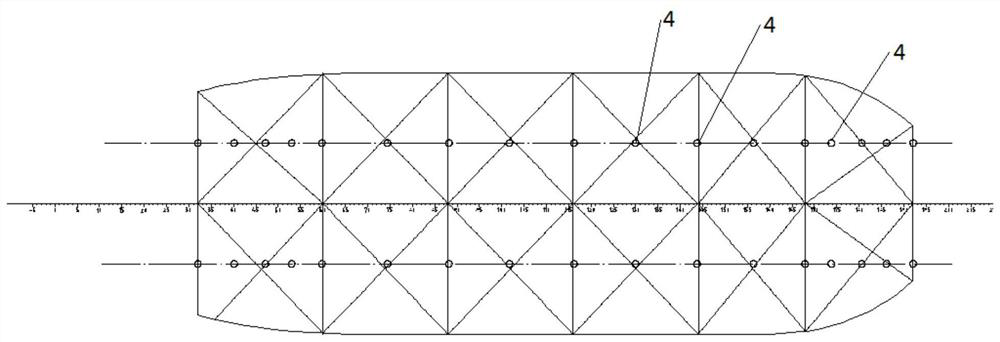

[0041] This embodiment provides a specific implementation of the tank bottom structure, such as figure 1 As shown, the bilge structure is suitable for being connected under the hull 1 , and the hull 1 in the prior art can be transformed to form a new bottom-riding barge. The bilge structure 2 includes at least several ballast tanks 3 .

[0042]The ballast tank 3 is usually connected with a valve, and water can enter the ballast tank 3 by opening the valve, thereby increasing the draft of the bottom barge formed by connecting the bilge structure 2 to the hull 1, and the water depth that can be operated is also greatly increased. increase, the full-load draft of the barge is greatly improved without changing the no-load draft of the barge, so that in areas with large tidal ranges or deep water depths, the hull can meet the operating requirements, and only the sitting in the existing technology is required. The transformation of bottom barges or cargo ships has low cost and good ...

Embodiment 2

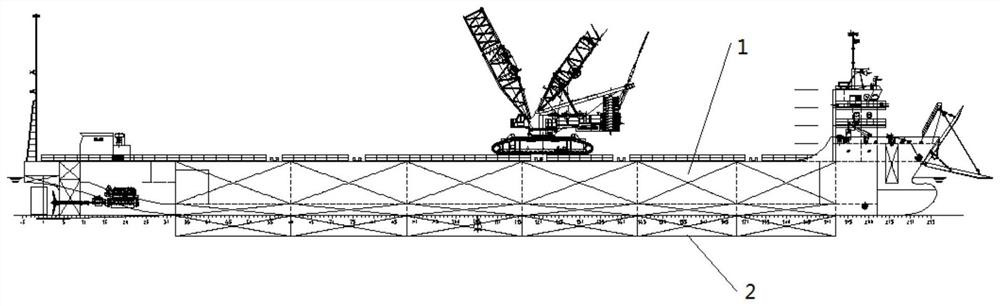

[0055] This embodiment provides a bottom barge, such as image 3 As shown, the sitting-on-bottom barge includes a hull 1 and the bilge structure 2 provided in the above embodiment connected to the hull, and the hull 1 has at least two bottoms.

[0056] The bottom barge is used for offshore wind power operations, and is especially suitable for the installation of wind power equipment in shallow water or even extremely shallow places. Wherein the hull 1 has at least two bottoms to ensure that the bottom barge has sufficient bottom strength to ensure the safety of the bottom construction. The hull 1 can be a double bottom barge in the prior art, which has a large enough bearing capacity .

[0057] However, the depth of the original ship in the prior art is limited, and when the water level reaches the full load draft, the ship must be hoisted and stopped. Compared with the barge sitting on the bottom, the sitting time on the bottom is longer, which can improve the working effic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com