Warhead active fragment with sealing layer and preparation method and application thereof

A warhead and sealing layer technology, applied to explosives, etc., can solve the problems of high reaction critical speed and low loading ratio, and achieve the effects of improving production efficiency, simplifying process, and improving damage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

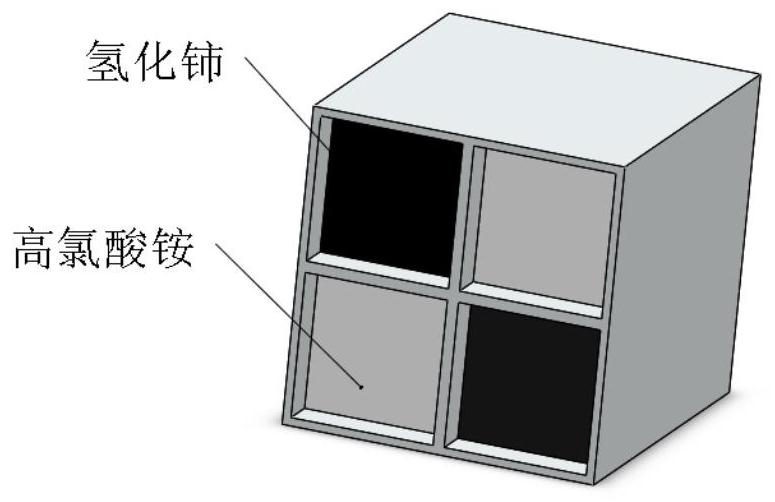

[0030] A warhead active fragment with a sealing layer, the active fragment includes a shell, a rare earth hydride, a strong oxidant and a sealing layer;

[0031] The shell is a hollow cuboid, and there is a cross grid inside the shell, that is, the cross grid divides the inner cavity of the hollow cuboid into four cavities in the height direction of the cuboid;

[0032] The rare earth hydride is preferably cerium hydride, with a particle size of 10 μm;

[0033] The strong oxidizing agent is ammonium perchlorate;

[0034] Rare earth hydrides and strong oxidants are alternately filled in different cavities of the shell; as figure 1 shown;

[0035] The material of the shell is Ta, the wall thickness of the shell is 0.3mm, and the wall thickness of the grid is 0.3mm.

[0036] A kind of preparation method of the warhead active fragment with sealing layer is:

[0037] (1) Put Ta 2 o 5 The powder is mixed with PMMA and added with water to prepare Ta 2 o 5 slurry. The slurry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com