Yarn for manufacturing recyclable environment-friendly hotel slippers capable of being repeatedly washed by many times

A technology of multiple repetitions and yarns, applied in the direction of yarn, filament/thread forming, fiber processing, etc., can solve the problems of large passenger flow, non-environmental protection, and lack of elasticity in hotels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

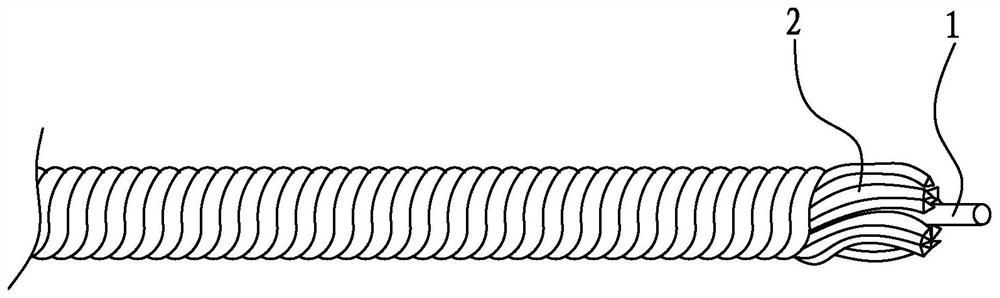

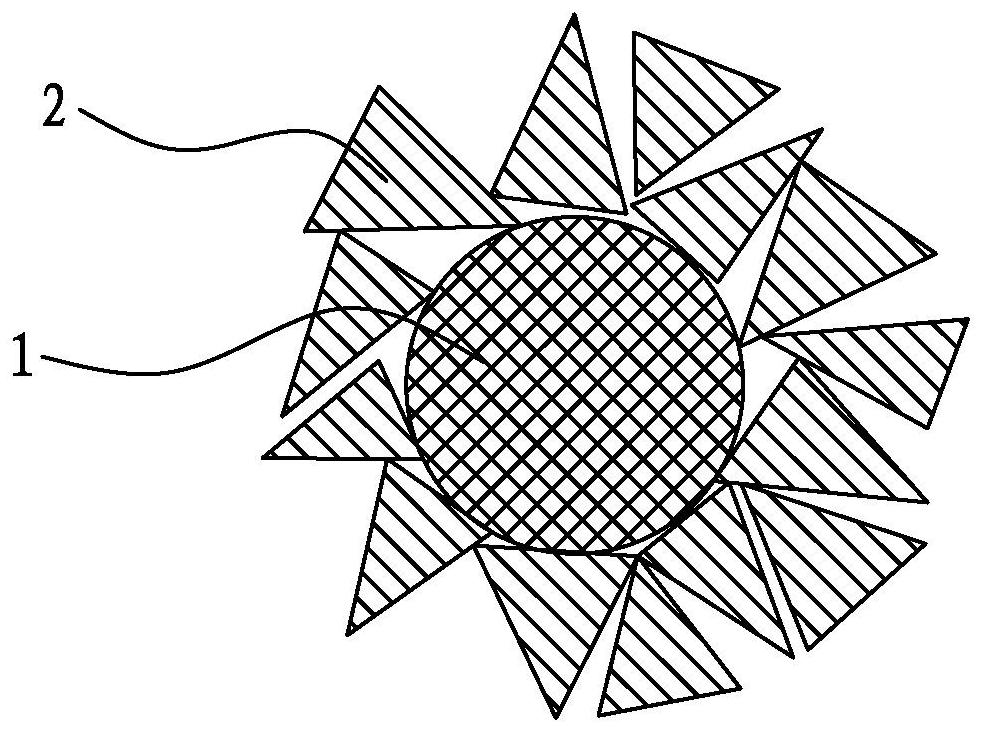

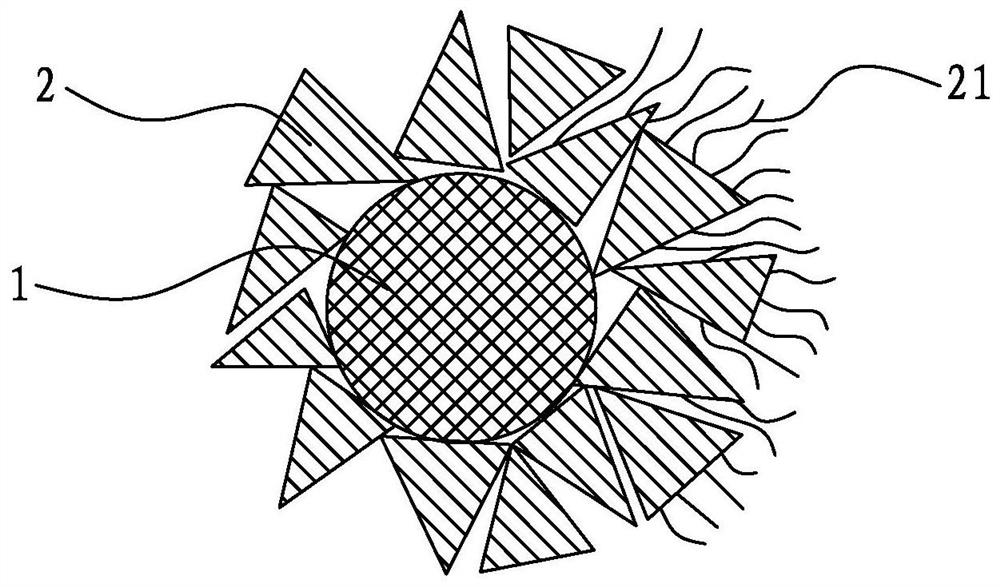

[0023] see figure 1 , figure 2 and image 3 , the invention discloses a yarn for making recyclable environmentally friendly hotel slippers that can be washed repeatedly, the yarn is made of a spandex yarn 1 and a bundle of bright nylon yarn 2 containing multiple roots through the spinning process A plurality of bright nylon filaments 2 wrap spandex filaments 1 inside.

[0024] The yarn of the present invention uses spandex yarn 1 as the inner core and a bunch of shiny nylon yarns 2 containing multiple roots in empty or machine-wrapped spandex yarns 1 to form a super-elastic composite yarn; because bright nylon yarns 2 have good elasticity , wear-resisting, high hardness, and glossy nylon yarn 2 has a good bright luster effect, making the appearance of the yarn brighter and more lustrous; the spandex yarn 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com