Patents

Literature

33results about How to "Good gloss effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stone crystal surface treatment composition and manufacturing method thereof

InactiveCN104119803AImprove mechanical propertiesNot easy to penetratePolishing compositionsHigh resistancePolyolefin

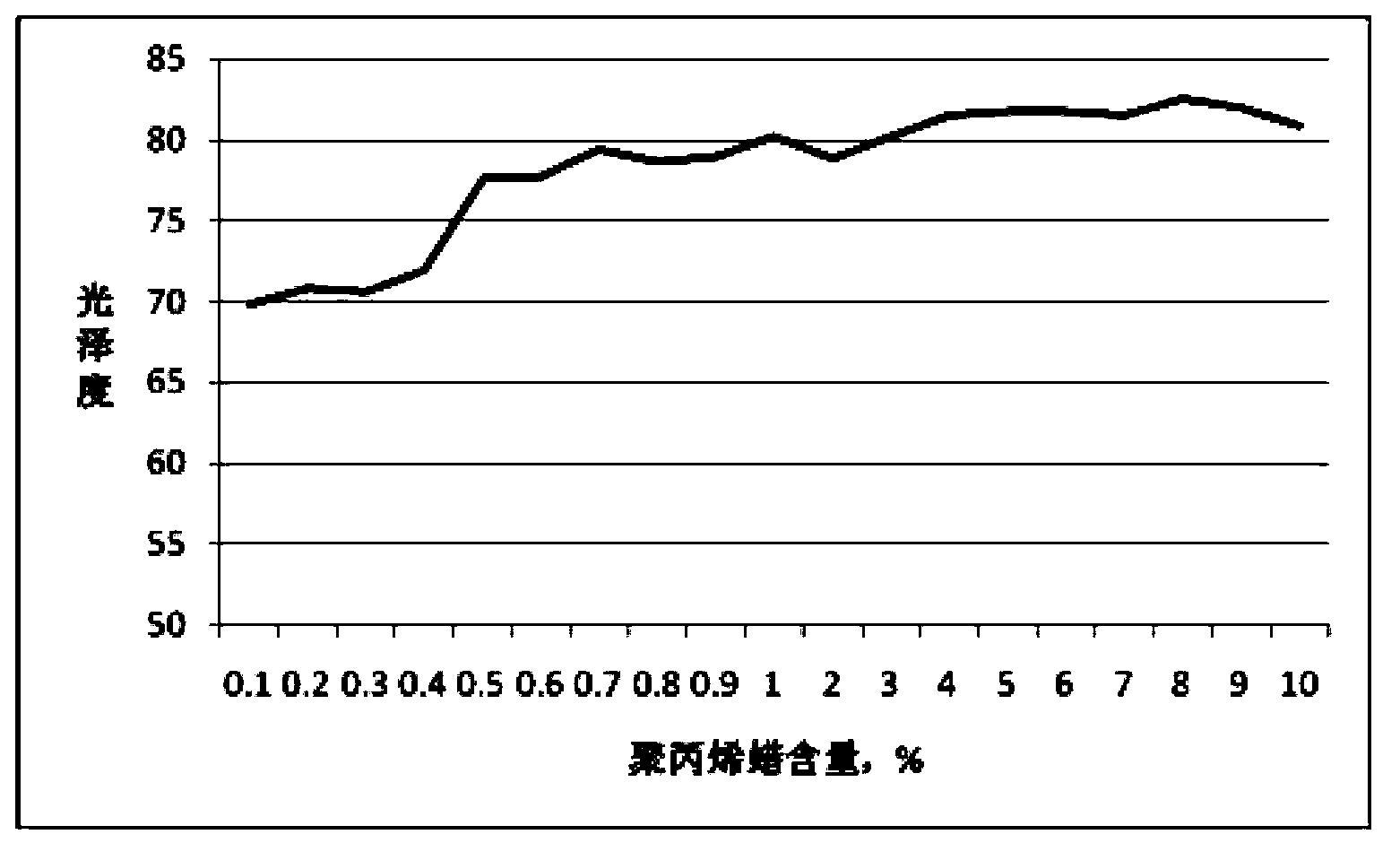

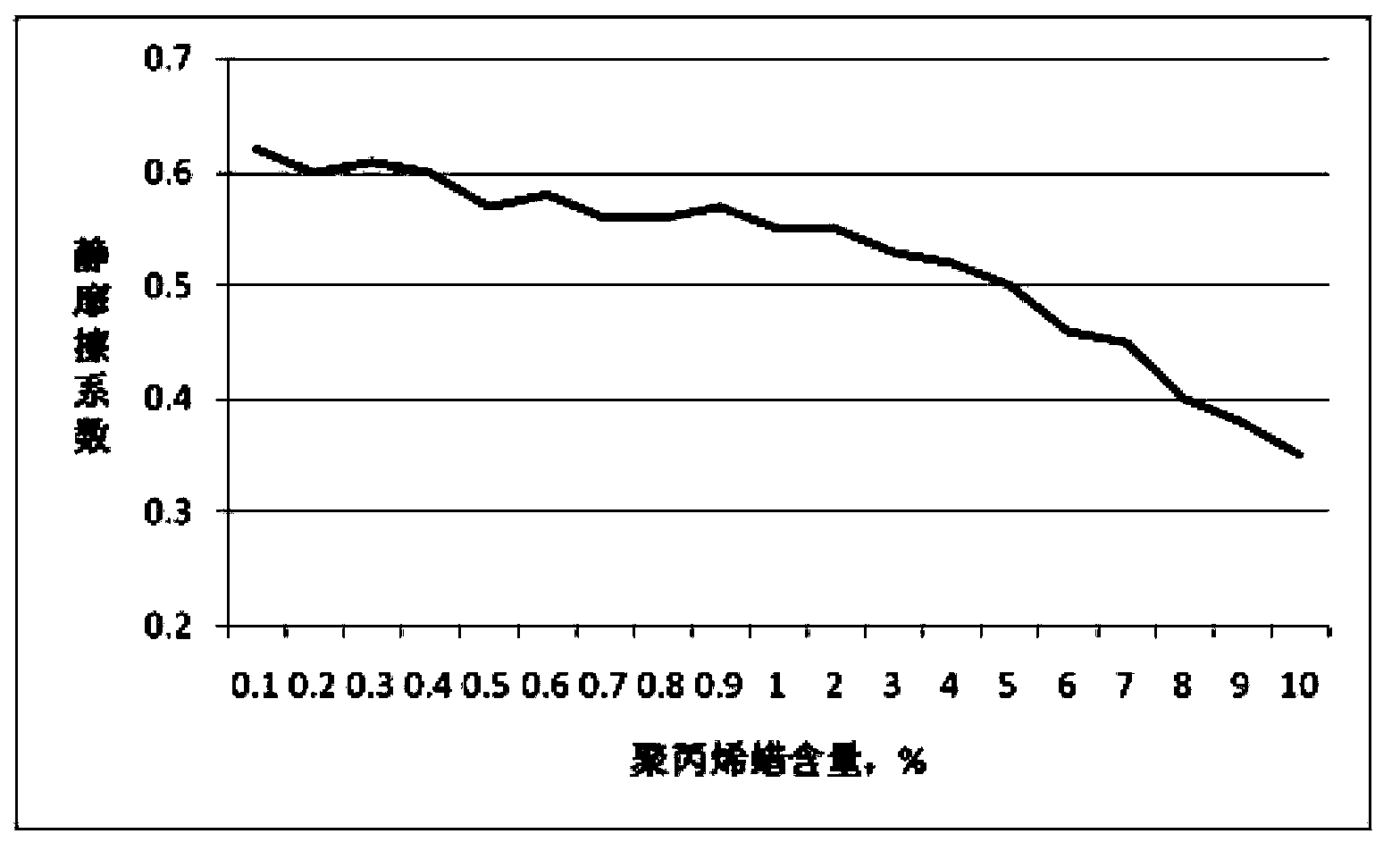

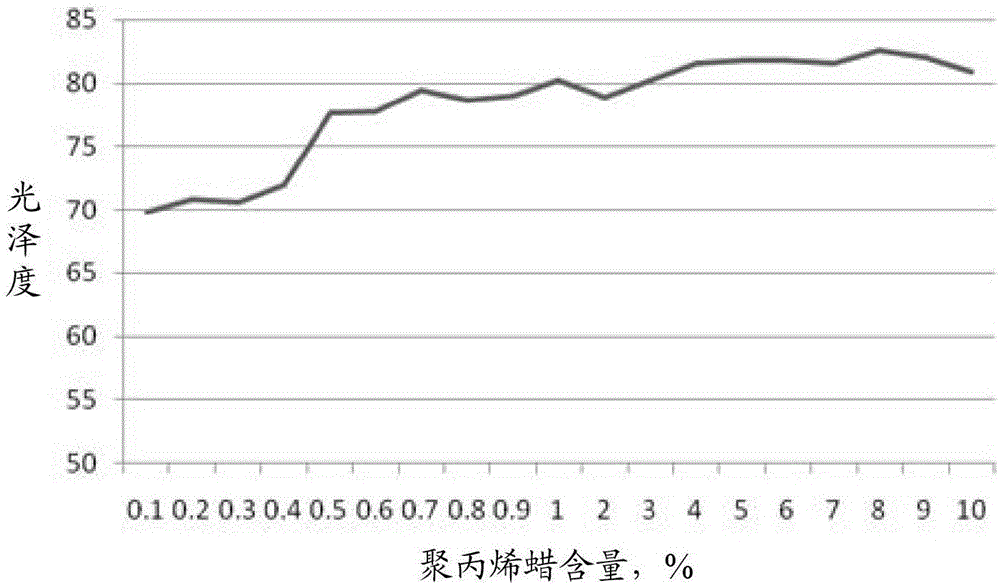

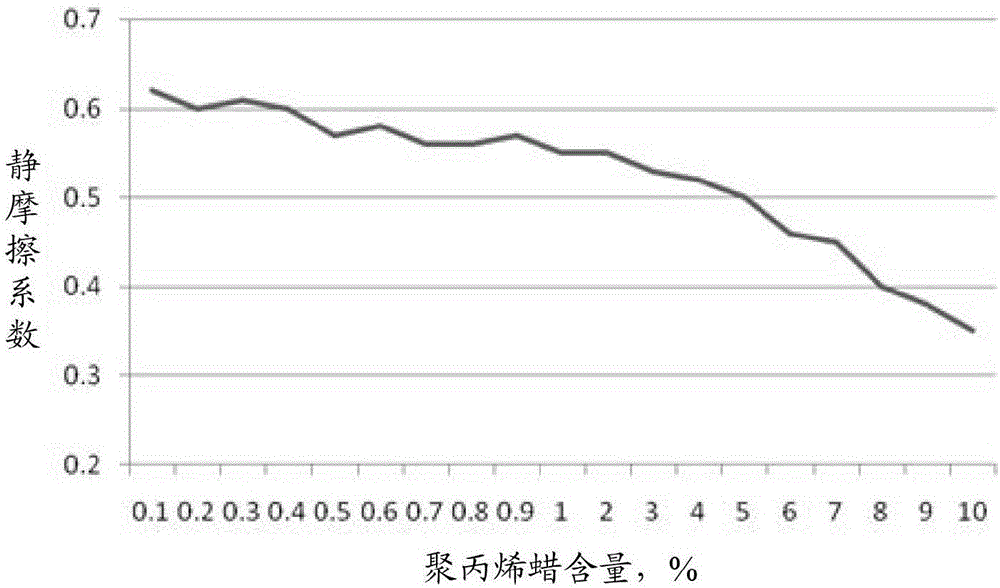

The invention discloses a stone surface treatment crystallizing agent comprising the following components in percentage by weight: 0.5-5% of polyolefin wax, 10-30% of fluorosilicic acid or fluorosilicate, 1-6% of acidity regulator, 0.5-5% of quick drying agent and the balance of water, wherein the polyolefin wax is added in an emulsion form, and the solid content of the polyolefin wax emulsion is kept within the range of 20-60%. The crystallizing agent disclosed by the invention can be used for crystallizing stones such as marble, waterstone or special granite and simultaneously hardening and brightening the surface of a stone floor so as to provide high glossiness and improved slip resistance for the crystal surface of the floor while protect the floor. Meanwhile, the treated stone surface has enhanced mechanical performance as well as higher wear resistance and chemical corrosion resistance, and water-soluble stains are not easy to permeate into the stone. The stone surface treated by using the crystallizing agent disclosed by the invention can be cleaned and treated by using water and is convenient and rapid in later-period maintenance and reduced in the maintaining cost as comparison with the stone surface treated by using a conventional waxing treatment method.

Owner:ECOLAB USA INC

Master batch composition, compound board and preparation method of compound board, and refrigeration plant

InactiveCN103113703AReduce light transmissionImprove anti-photooxidative aging functionPolyolefinEngineering

The invention discloses a master batch composition, a compound board and a preparation method of the compound board, and a refrigeration plant. The master batch composition comprises 20-40 parts by weight of a matrix resin which is selected from HIPS (High Impact Polystyrene), 30-50 parts by weight of a flexibilizer which is selected from at least one of SBS (Styrene-Butadiene-Styrene), butadiene styrene rubber, naphthenic oil, PE-g-PS (Polythene-g-Polystyrene), POE-g-PS (Polyolefin-g-Polystyrene), EPDM-g-PS (Ethylene-Propylene-Diene Monomer-g-Polystyrene), 3-20 parts by weight of pigment, 0-10 parts by weight of a brightener, 0-3 parts by weight of an anti-light and oxygen ageing agent and 5-20 parts by weight of an antistatic agent. Thus, the master batch composition can effectively prepare a liner and can further increase the strength of the surface of the liner, increase the anti-cracking ability and particularly the resistance to chemical corrosions such as oils, cleaning agents and the like, increase the weather resistance and the surface gloss and increase the antistatic and dirt-proof functions, so that the liner is easier to clean.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

Button polishing method

ActiveCN103639884AGood lookingReduce labor intensityPolishing machinesLapping machinesMass ratioUltimate tensile strength

The invention discloses a button polishing method. High-frequency porcelain particles, buttons to be polished, silica sand powder, chemical polishing agents are put in a duplex vortex polishing machine, and water is added to immerse the materials; the mass ratio of the buttons to be polished and the high-frequency porcelain particles is 1:2-1:7, and the adding amount of the silica sand powder and the chemical polishing agents are 2% to 7% and 0.5% to 1.5% of the total mass of the solid materials; the size of the high-frequency porcelain particles is 2.5*8.0mm or 3*3mm; first polishing time is set, and the rotation speed of the vortex polishing machine is 100 revolutions / min-180 revolutions / min; second polishing time is set according to the first polishing effect till the button lustre meets requirements, and the buttons are cleaned. According to the polishing method, comparing with a traditional method, the polishing efficiency is improved by 3 times to 4 times, the polishing effect is stable, the production period is shortened, the labor cost and the worker labor intensity are reduced, and the produced button appearance is outstanding.

Owner:广东康派环创科技有限公司

Three-layer anti-hair loss hair conditioner

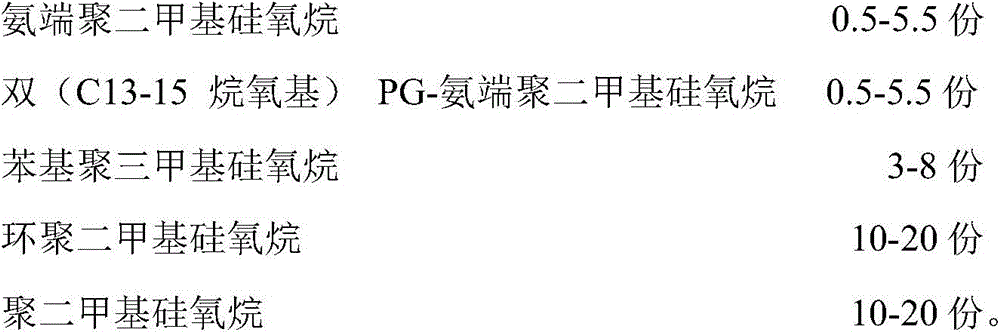

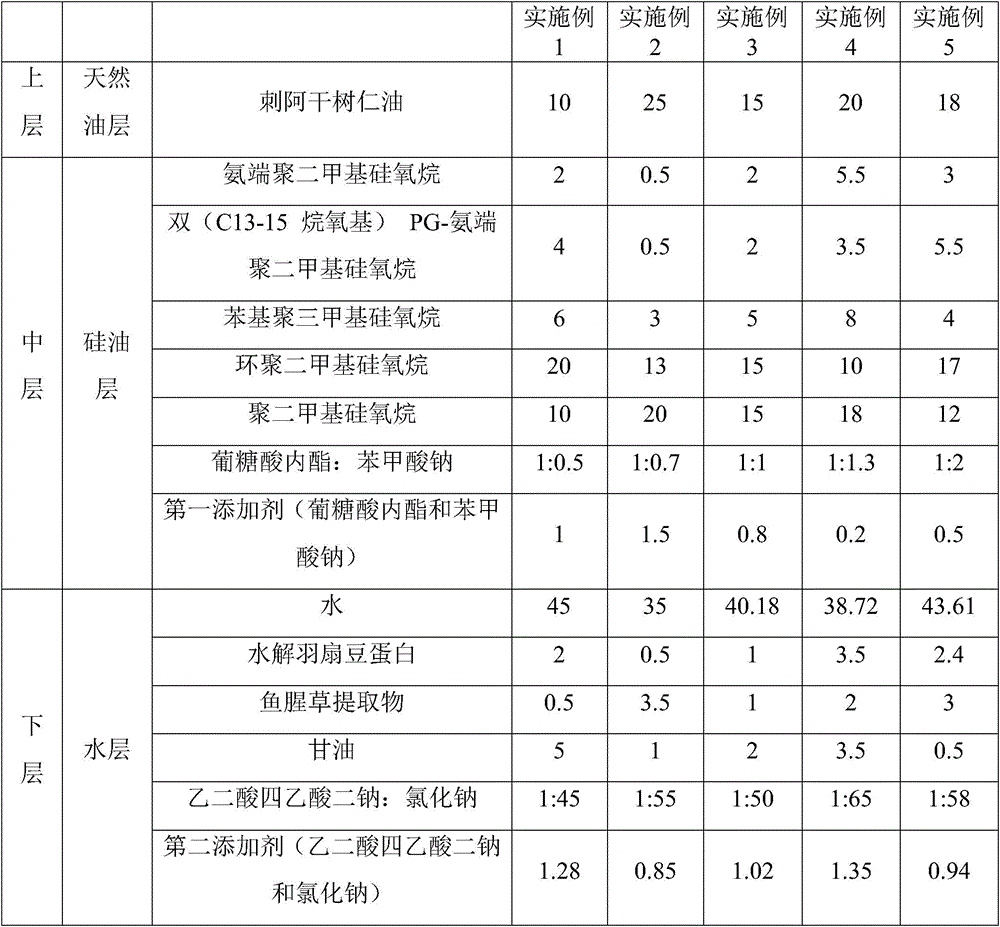

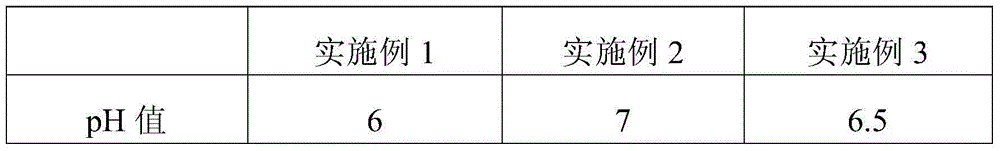

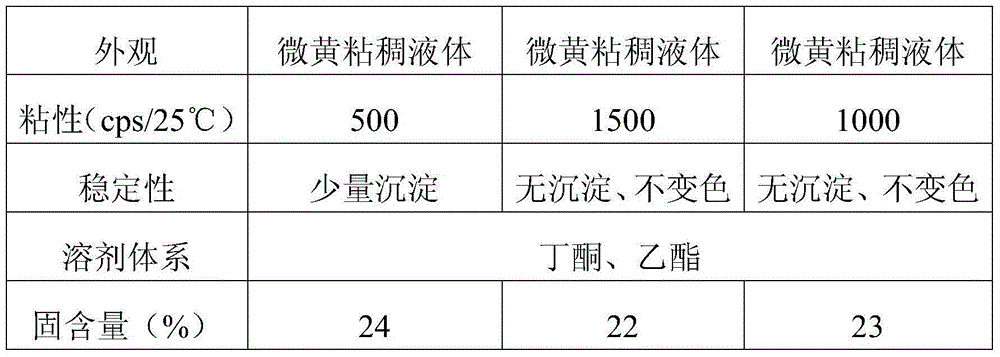

ActiveCN105640826AEasy to combAvoid roughnessCosmetic preparationsHair cosmeticsEngineeringSilicone oil

Owner:HANGZHOU XINYUE COSMETICS CO LTD

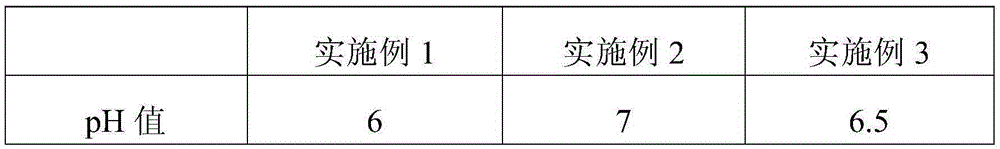

Luster improving polishing treatment agent for synthetic leather and preparation method thereof

The invention relates to a luster improving polishing treatment agent for synthetic leather and a preparation method thereof. The treatment agent comprises alkyd resin, nitro-cotton, butanone, butyl ether, ethyl ester, silica extinction powder, organic modified methyl phenyl silicone oil and a dispersing agent. The luster improving polishing treatment agent for synthetic leather is a novel material for back-section printing of synthetic leather. By application of the treatment agent, the leather surface of synthetic leather is natural in gloss, clear in color and luster and high in temperature resistance and can be subjected to embossing, and polished synthetic leather has a good surface brightening effect, a good leather effect and excellent comprehensive effects.

Owner:浙江宝泽高分子材料有限公司

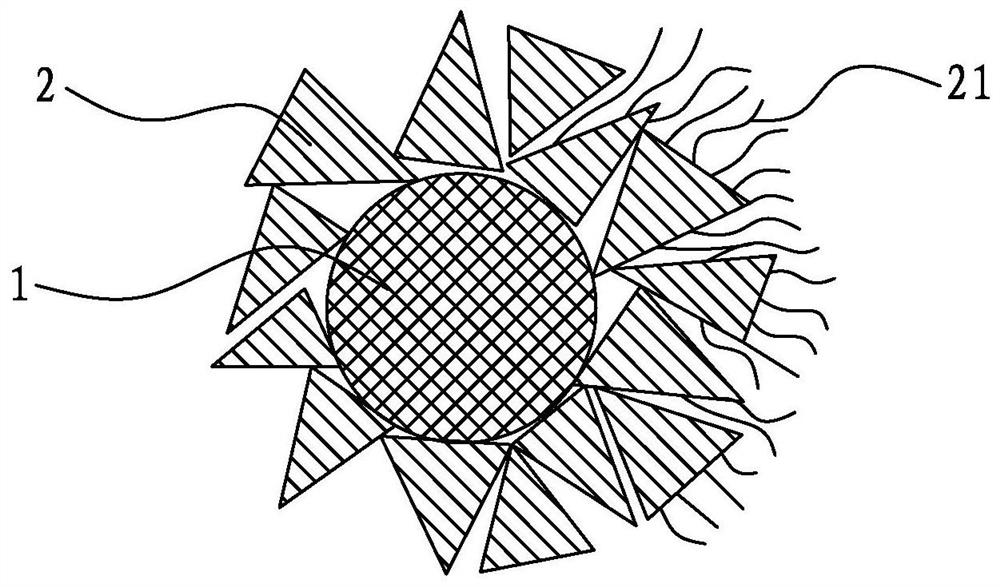

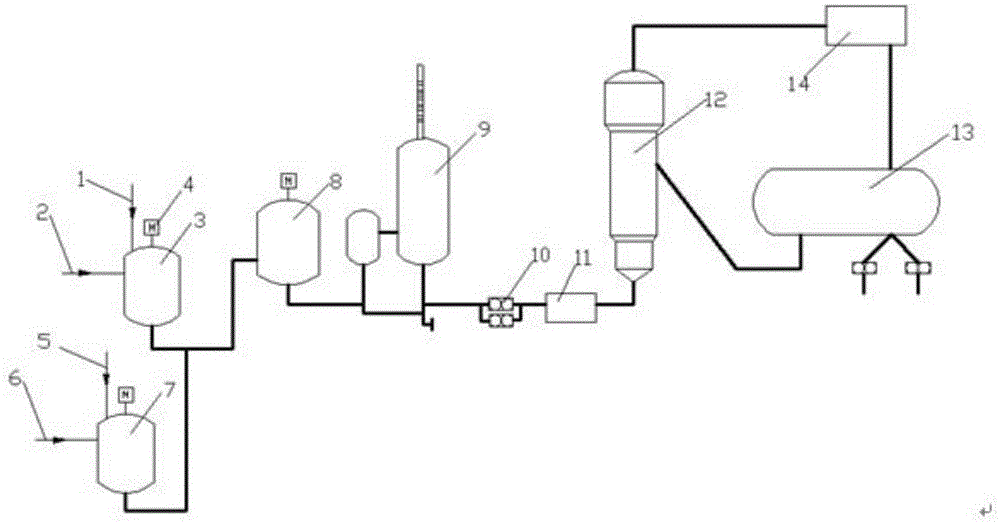

Production method of fiber used for grinding and polishing

InactiveCN103510178AImprove cooling effectGood effectLapping machinesMonocomponent polyesters artificial filamentFiberMetallurgy

The invention belongs to the field of grinding and polishing, and specifically relates to a production method of a fiber used for grinding and polishing. According to the production method, a fine abrasive powder is added into the raw material of the fiber, wherein the weight of the fine abrasive powder is 0.1 to 20% of the total weight of the raw material. The fiber produced by the production method possesses polishing function, can be used for replacing sand paper and abrasive cloth, is capable of avoiding a plurality of disadvantages of sand paper and abrasive cloth, and can be used as dust cloth.

Owner:河南星智发明电子科技有限公司

Paint layer vibration polishing protection clamp for vane fan-shaped assemblies

ActiveCN106272018AAvoid bumps and scratchesFree mobility is not affectedEdge grinding machinesPolishing machinesEngineeringMechanical engineering

The invention discloses a paint layer vibration polishing protection clamp for vane fan-shaped assemblies. The paint layer vibration polishing protection clamp comprises a horizontal mounting rod, a plurality of horizontal supporting rods and a plurality of longitudinal circular rings. The longitudinal circular rings are connected through the horizontal supporting rods to form a cylindrical cage-type structure. The vane fan-shaped assemblies are fixed to the mounting rod in the cage-type structure and make spiral movement in the three-dimensional direction along with abrasives in a working cavity of a vibration polishing machine, and the cage-type structure effectively prevents the scratching and bumping between the vane fan-shaped assemblies. Meanwhile, the abrasives are machined through the gap between clamp structural members, and the free flowing of the fan-shaped assemblies is not affected.

Owner:AECC AVIATION POWER CO LTD

Finishing method of functional coating of dyed fabric

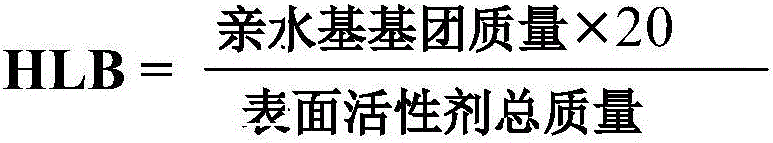

ActiveCN103696265AGood solvent migration fastnessInhibit migrationFibre typesTextile shapingDisperse dyeOrganic solvent

The invention discloses a finishing method of a functional coating of dyed fabric, which specifically comprises the steps of anti-dye transfer finishing, water and oil proofing finishing, polyurethane coating finishing, polyester coating finishing and calendering finishing to obtain a functional coating-finished textile. The prepared textile has a special coating product style and overcomes the problem of dye transfer caused by an organic solvent or non-ionic surfactant existing in the disperse dye; moreover, the finishing method is low in production cost, has relatively strong operability and is suitable for industrial application.

Owner:常州喜莱维纺织科技有限公司

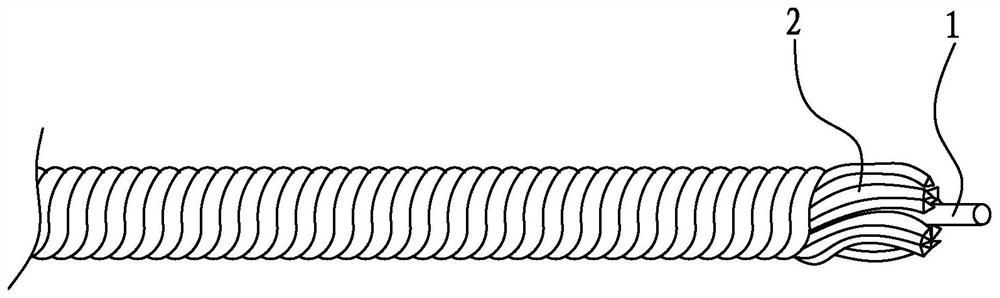

Terylene polishing fiber and production method thereof

InactiveCN103510185AGood gloss effectImprove cooling effectMonocomponent polyesters artificial filamentArtifical filament manufactureYarnFiber

The invention belongs to the field of polishing, and specifically relates to a terylene polishing fiber and a production method thereof. According to the production method, raw materials used for producing terylene fibers and brown fused alumina micropowder are mixed uniformly at a ratio, and production technology and equipment used for producing terylene fibers are used so as to obtain the terylene polishing fiber. The terylene polishing fiber can be used for removing abrasive dust and polishing objects easily, can be used for polishing unevenness surfaces with excellent effect, and is capable of taking a portion of the effects of emery cloth, sand paper, rag, cotton yarn, abrasive paste and polishing agent; and polishing effect and heat dissipation effect are excellent.

Owner:河南星智发明电子科技有限公司

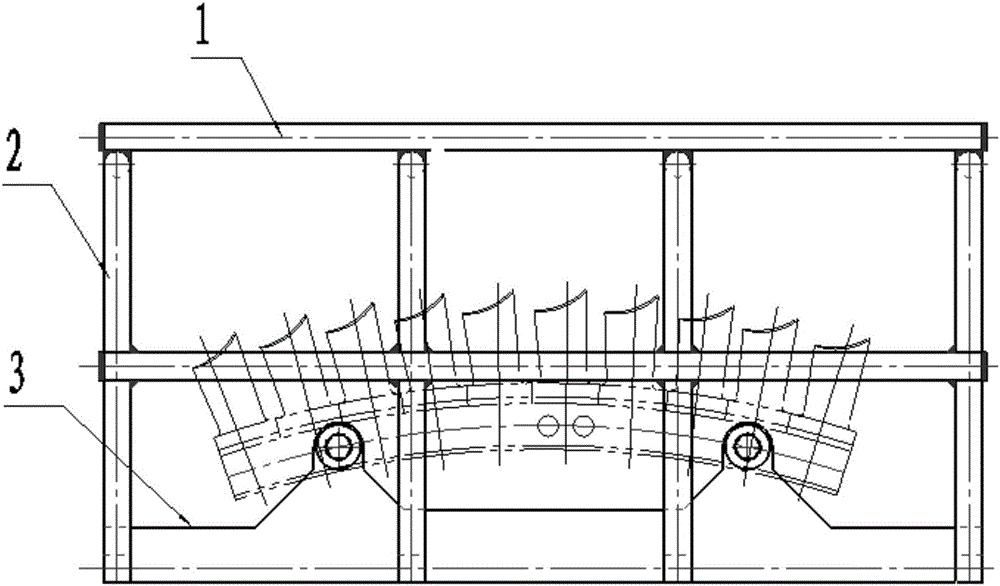

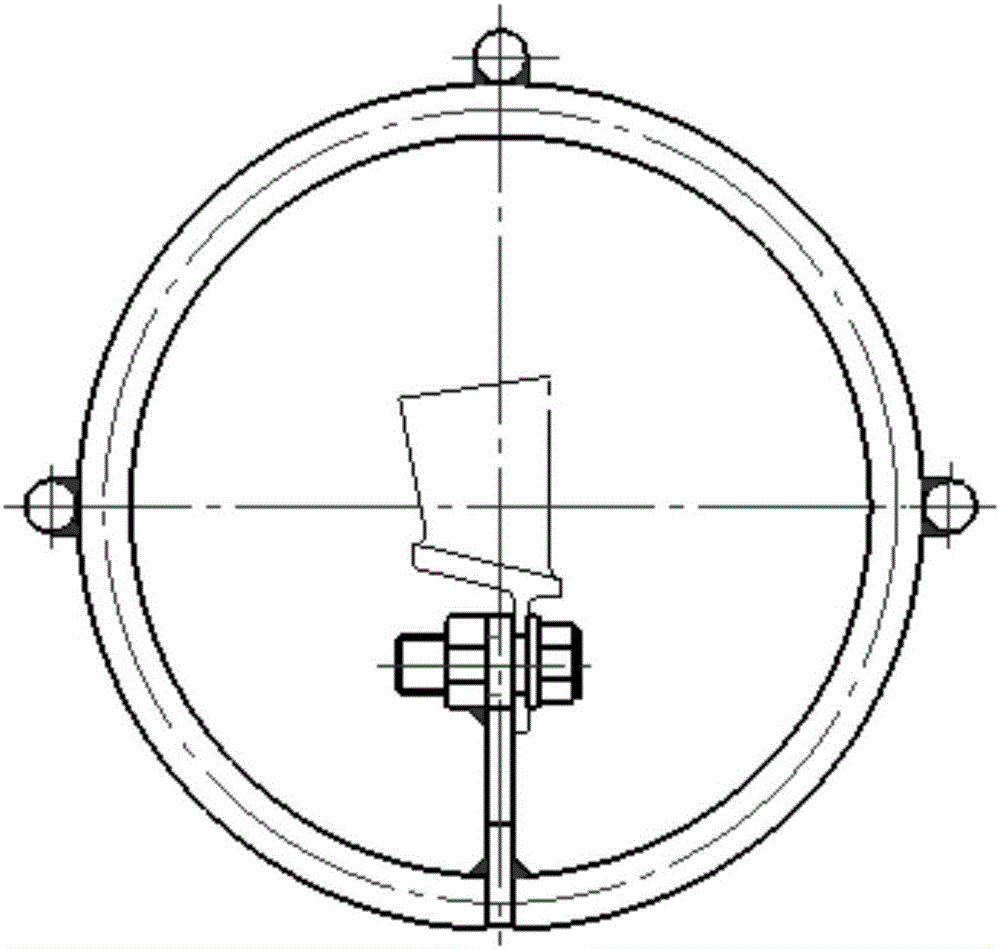

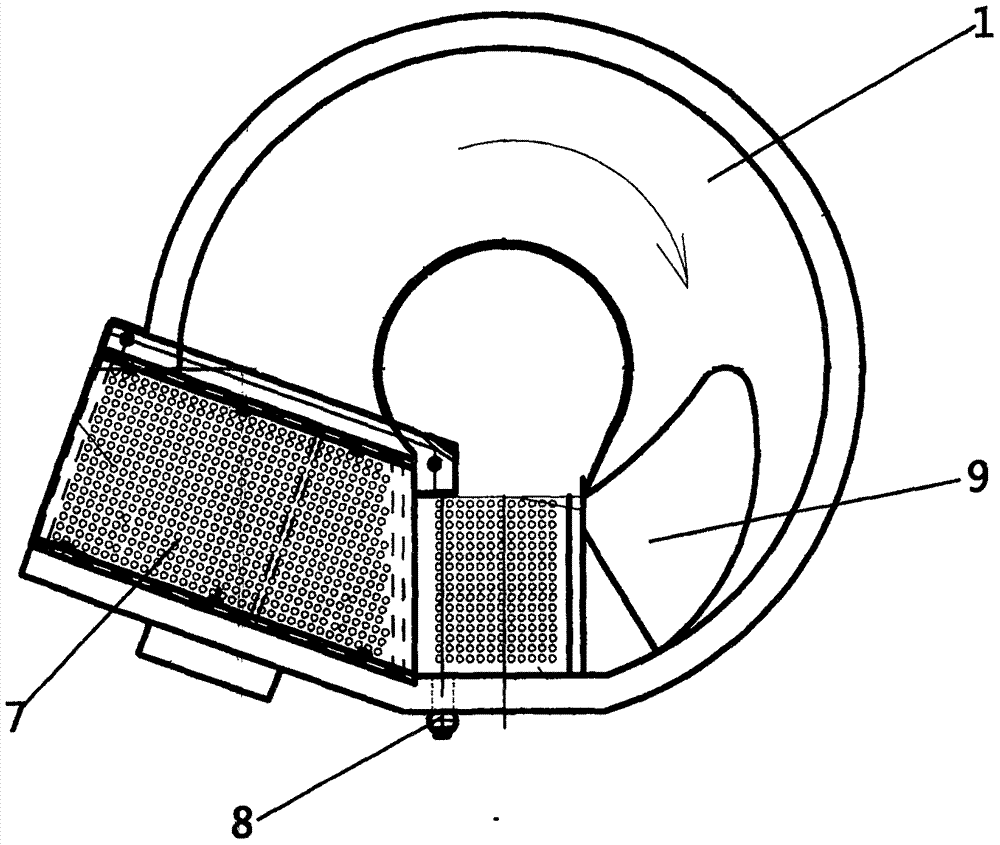

A vibrating light decoration protection fixture for the paint layer of the fan-shaped component of the blade

ActiveCN106272018BGood gloss effectImprove processing efficiencyPolishing machinesPositioning apparatusLacquerMechanical engineering

The invention discloses a paint layer vibration polishing protection clamp for vane fan-shaped assemblies. The paint layer vibration polishing protection clamp comprises a horizontal mounting rod, a plurality of horizontal supporting rods and a plurality of longitudinal circular rings. The longitudinal circular rings are connected through the horizontal supporting rods to form a cylindrical cage-type structure. The vane fan-shaped assemblies are fixed to the mounting rod in the cage-type structure and make spiral movement in the three-dimensional direction along with abrasives in a working cavity of a vibration polishing machine, and the cage-type structure effectively prevents the scratching and bumping between the vane fan-shaped assemblies. Meanwhile, the abrasives are machined through the gap between clamp structural members, and the free flowing of the fan-shaped assemblies is not affected.

Owner:AECC AVIATION POWER CO LTD

Stone crystal face processing composition and preparation method of composition

InactiveCN106431496AImprove mechanical propertiesNot easy to penetratePolishing compositionsWaxEmulsion

The invention relates to a stone crystal face processing composition and a preparation method of the composition, and discloses a crystallization agent for processing a stone surface. The crystallization agent is prepared from, by weight, 0.5-5% of polyolefine wax, 10-30% of fluosilicic acid or fluorosilicate, 1-6% of acid regulator, 0.5-5% of fast dry agent and the balance water, wherein the polyolefine wax is added in the form of an emulsion, and the solid content of the polyolefine wax emulsion is within a range of 20-60%. The crystallization agent can be used for conducting crystal face processing on stone including marble, terrazzo and special granite, and can be used for hardening and lightening the surface of a stone floor at the same time; while protection is given to the floor, the crystal surface of the floor is made to have a high glossiness, and the non-skid property is improved. Meanwhile, the processed stone surface has an enhanced mechanical property and is more resistant to abrasion and chemical corrosion, and water-soluble stains are not prone to permeate into the stone. The stone surface processed with the crystallization agent can be washed with water; compared with conventional waxing treatment, later maintenance is convenient and fast, the maintenance cost is reduced.

Owner:ECOLAB USA INC

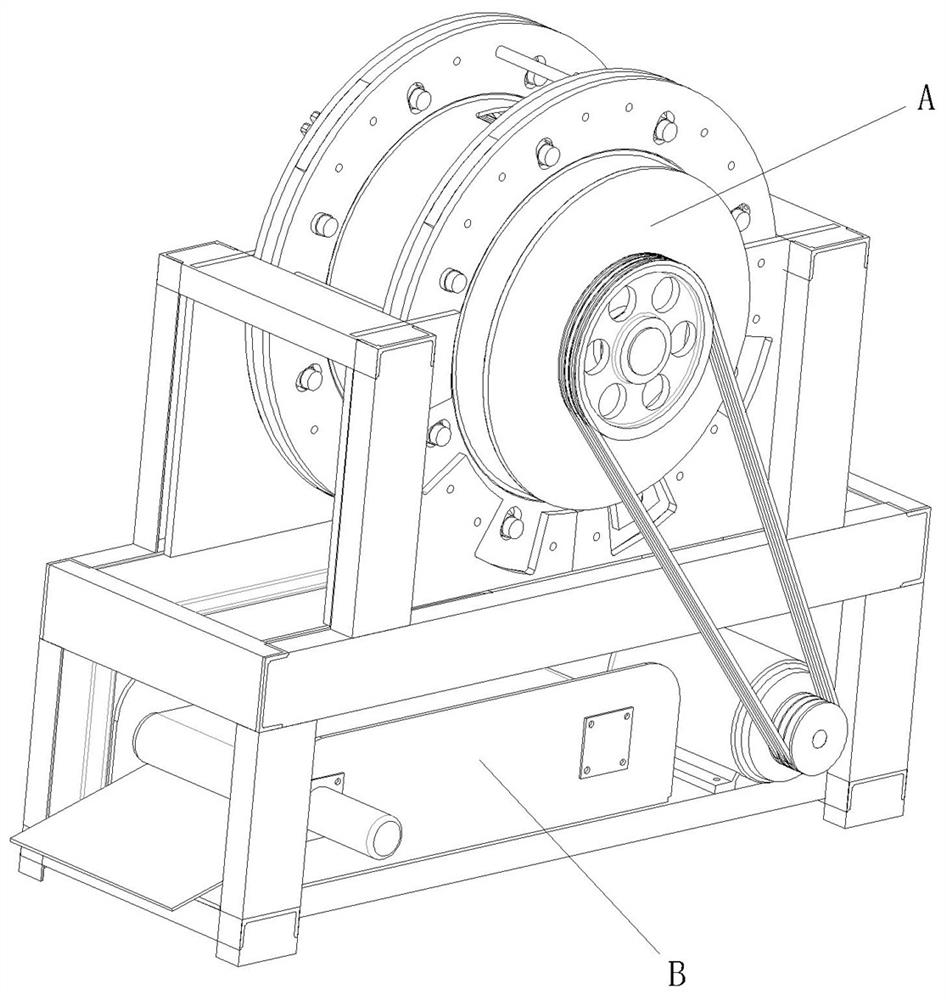

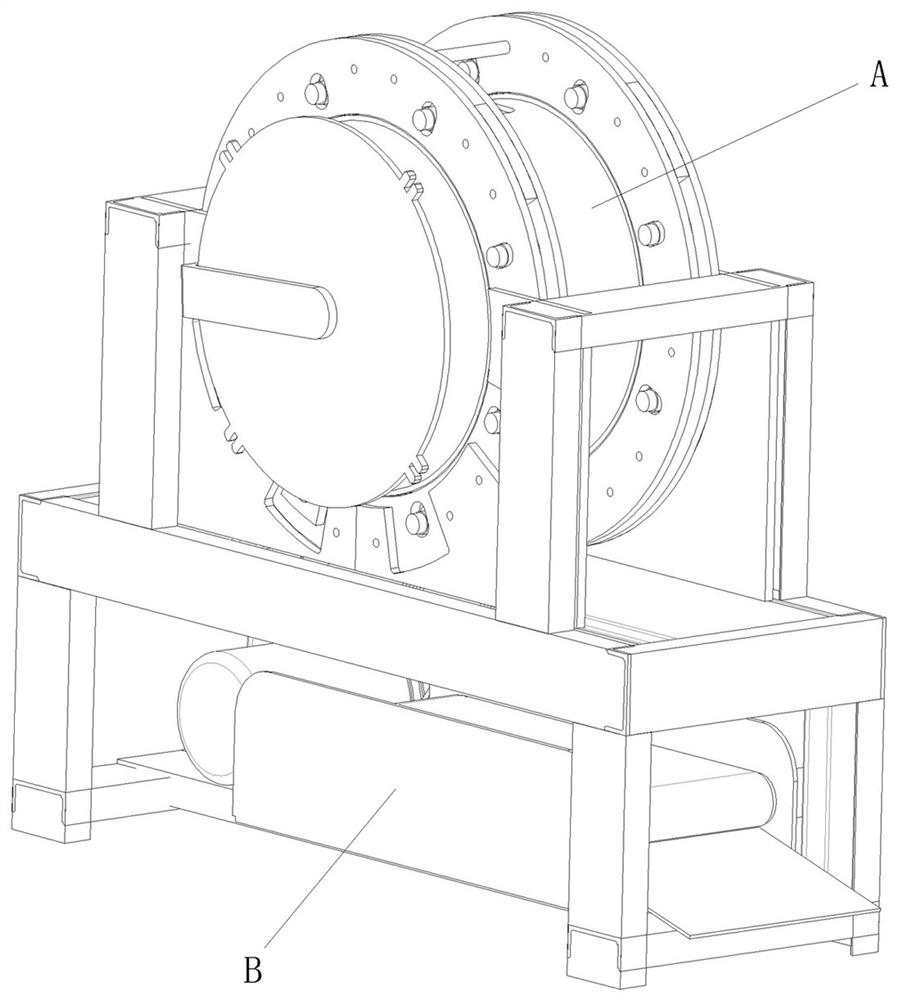

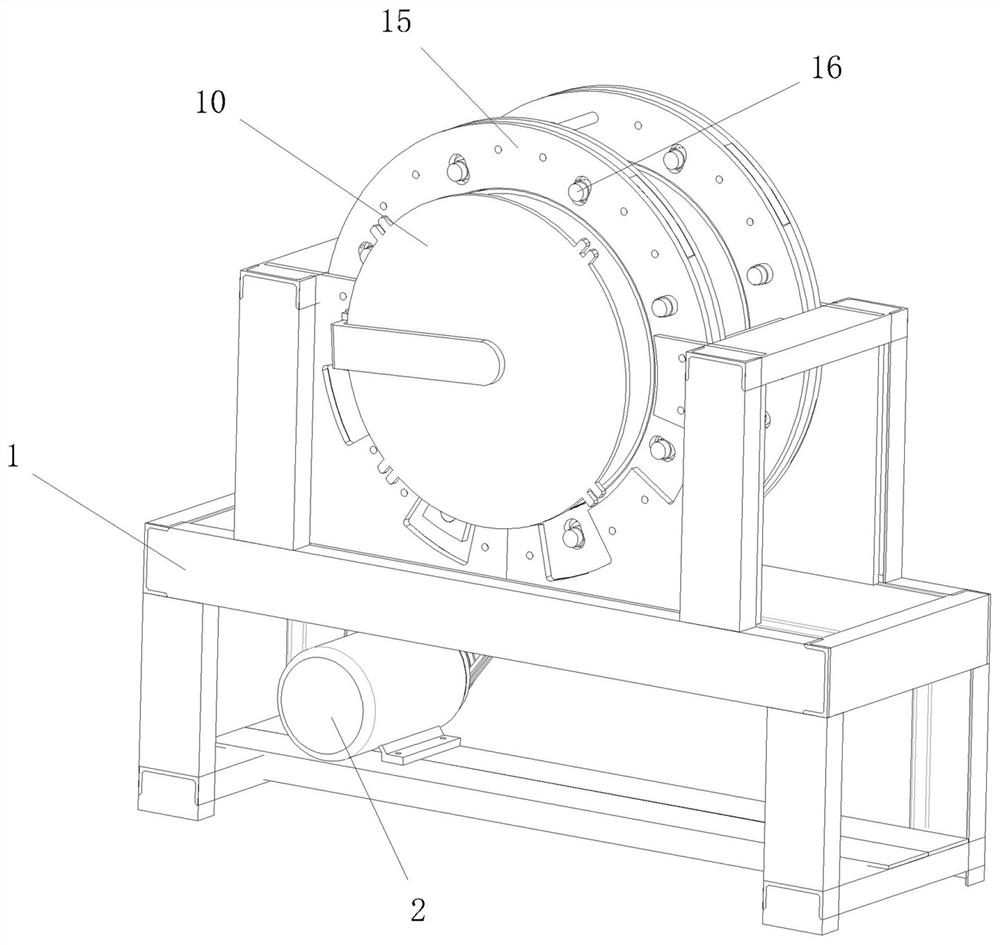

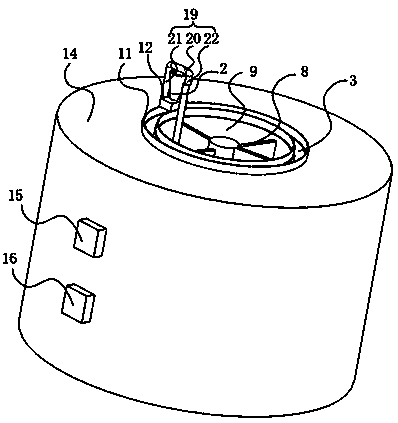

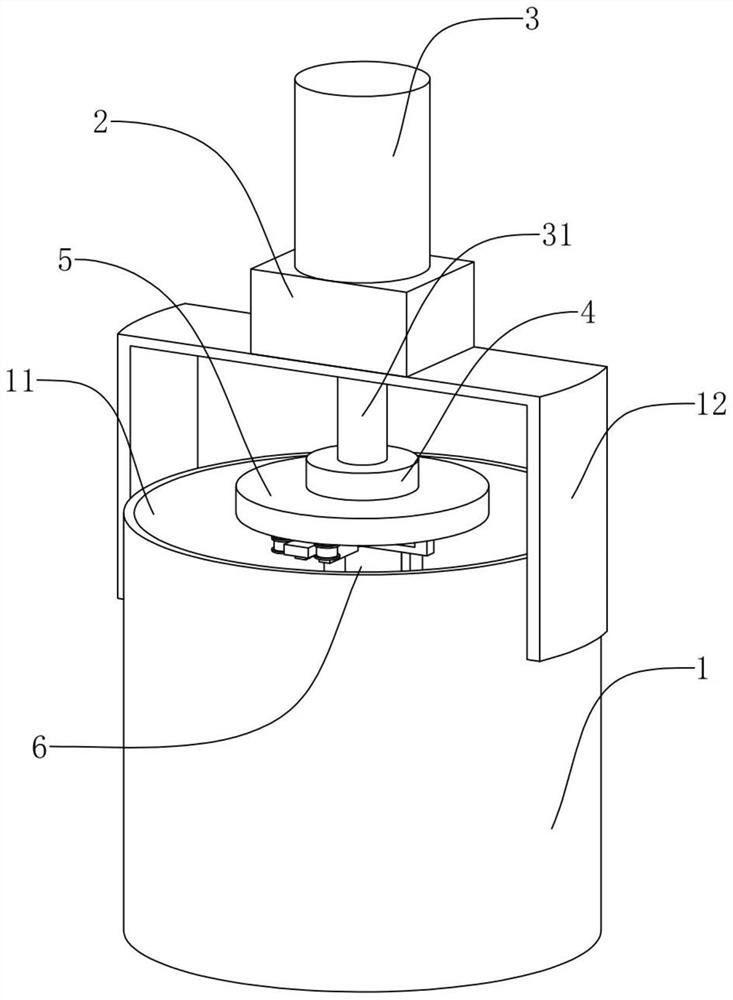

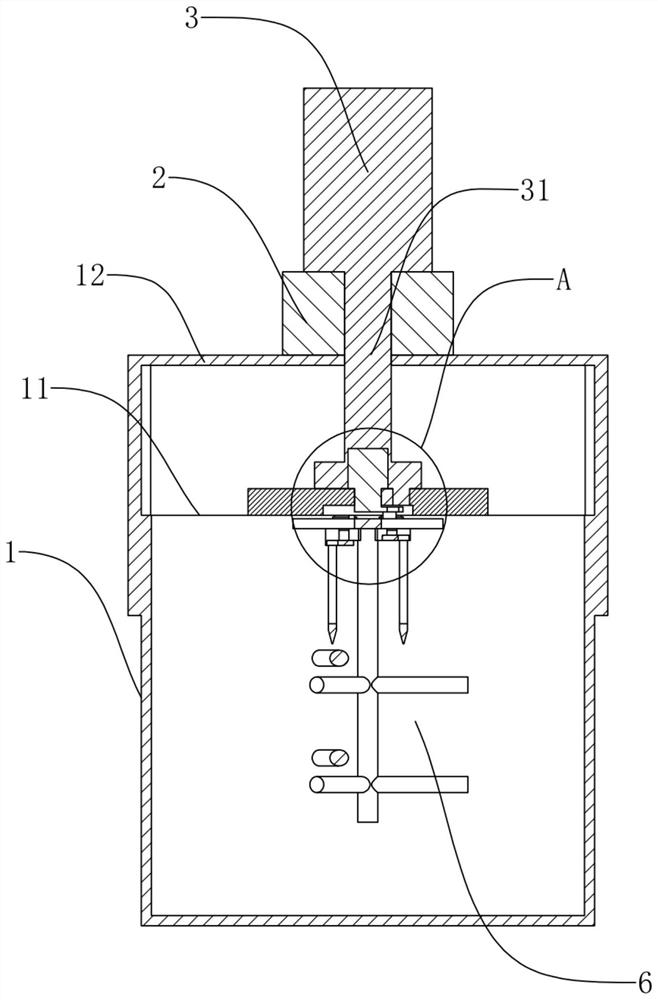

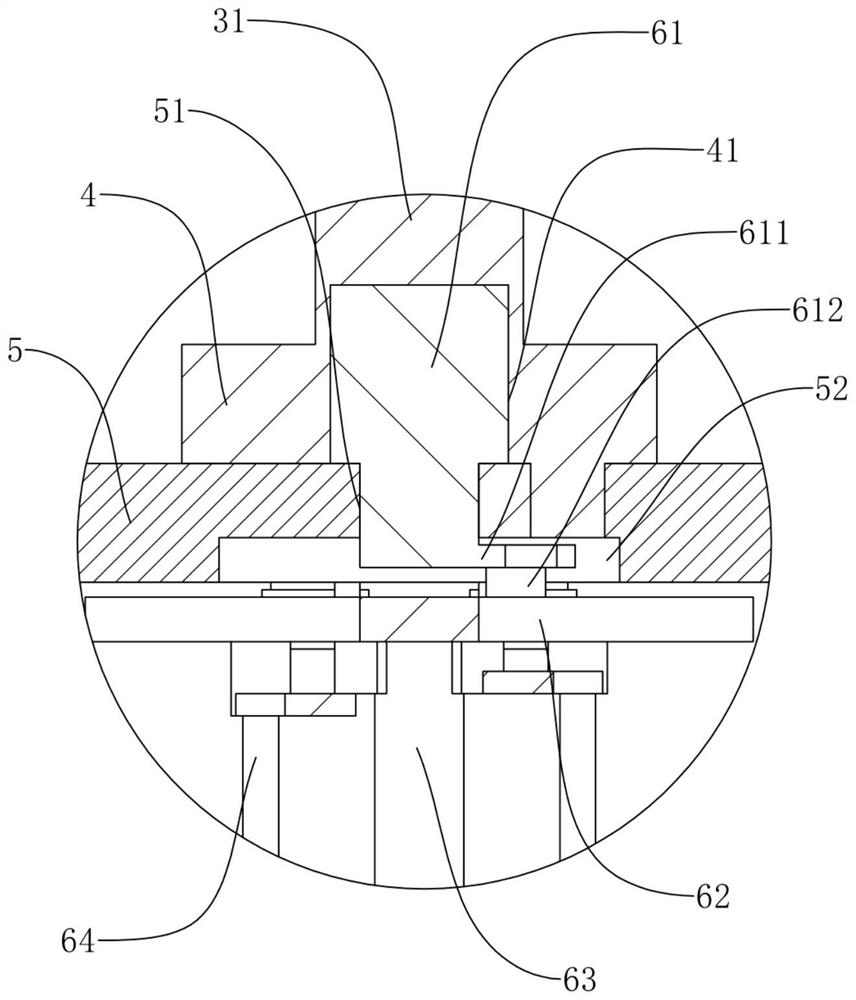

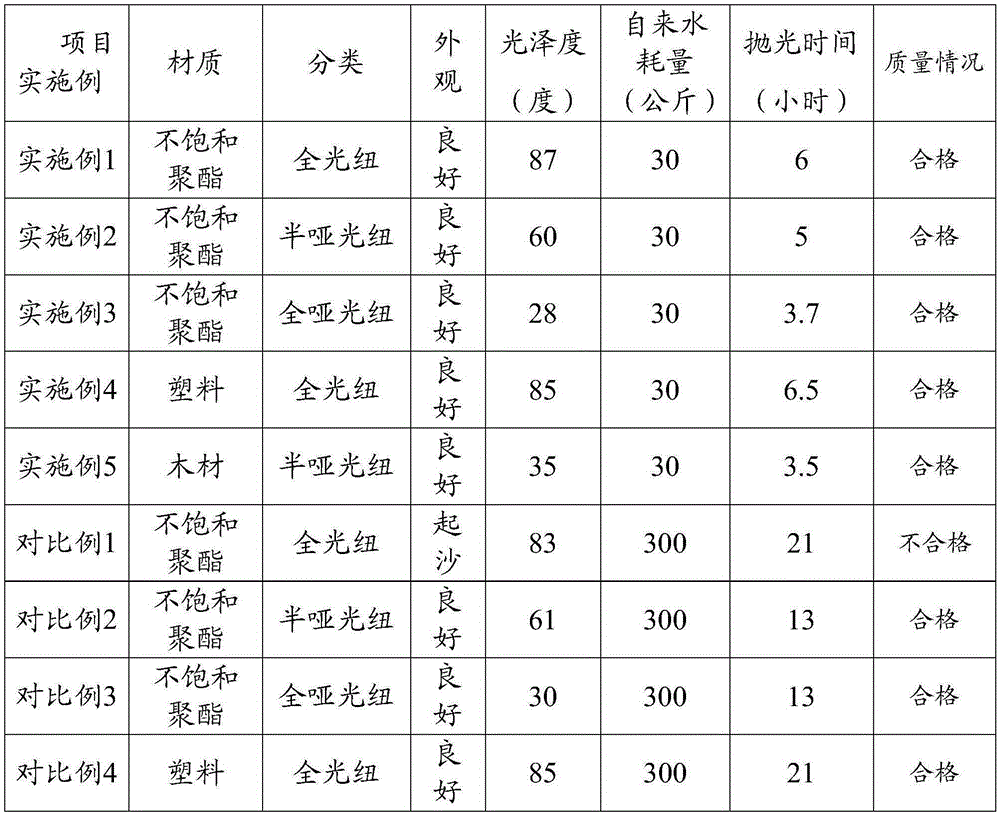

Drum-type workpiece polishing system and polishing method

ActiveCN112677028AEasy to handleGood gloss effectEdge grinding machinesPolishing machinesPolishingElectric machinery

The invention discloses a drum-type workpiece polishing system, and belongs to the technical field of polishing equipment. The drum-type workpiece polishing system comprises a rack, a workpiece polishing machine arranged on the rack, and an abrasive conveyor positioned below the workpiece polishing machine, wherein the workpiece polishing machine comprises a drum assembly, a motor driving the drum assembly to rotate, an inner cylinder arranged in the drum assembly and used for forming a grinding cavity, and a workpiece containing assembly arranged in the grinding cavity. In addition, the invention further discloses a workpiece polishing method. According to the drum-type workpiece polishing system and polishing method provided by the invention, workpieces are placed in a workpiece containing barrel, so that abrasives enter and exit from the workpiece containing barrel to polish the workpieces; after polishing is completed, the abrasives are discharged out of the workpiece polishing machine and conveyed by the abrasive conveyor so as to be collected, so that the polishing effect of the whole system is good; and a screening device does not need to be arranged, so that the equipment cost is reduced.

Owner:重庆优扬机械有限公司

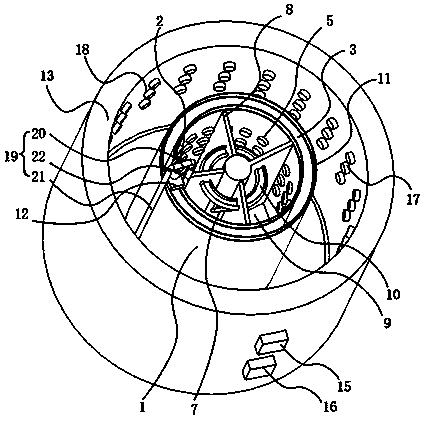

Double magnetic vibration polishing machine and method

InactiveCN107097143AIncrease profitReduce energy lossEdge grinding machinesPolishing machinesEngineeringKinetic energy

The invention discloses a double magnetic vibration polishing machine and method. The double magnetic vibration polishing machine comprises a base, springs, a first magnetic vibration device, a second magnetic vibration device and working grooves. The springs are arranged on the base and connected with the base and the working grooves. The magnetic vibration devices are symmetrically arranged between the base and the working grooves. The first magnetic vibration device and the second magnetic vibration device each comprise a permanent magnet and an electromagnet which are oppositely arranged up and down. The first magnetic vibration device or / and the second magnetic vibration device provide kinetic energy for the working grooves by electrifying the electromagnets. The double magnetic vibration polishing method comprises the steps that abrasives and workpieces are placed in the working grooves, and the first magnetic vibration device or / and the second magnetic vibration device provide the kinetic energy for the working grooves by electrifying the electromagnets, so that polishing work is completed on the abrasives and the workpieces in the working grooves. According to the double magnetic vibration polishing machine and method, vibration motors high in cost are not used, so that the equipment cost is reduced; and in addition, the magnetic vibration devices are simple in structure, the vibration frequency is convenient to adjust, and the service life is prolonged.

Owner:大连浪卓表面设备制造有限公司

Wax polishing treatment agent for synthetic leather and preparation method of wax polishing treatment agent

The invention relates to a wax polishing treatment agent for synthetic leather and a preparation method of the wax polishing treatment agent. The wax polishing treatment agent for the synthetic leather is prepared from nitrocotton, butyl ether, ethyl ester, butyl ester, silicon dioxide matting powder, epoxy soybean oil, a dispersant and phenyl methyl silicone oil. All the components of the wax polishing treatment agent are coordinated with each other and have a synergistic action, the wax polishing treatment agent is good in temperature resistance, can be used for embossing and has an excellent surface-brightening effect after the wax polishing treatment agent is used for polishing, and the hand feeling is unique; the leather prepared by using the treatment agent is natural in luster, clear in color, excellent in wax brightening effect and good in comprehensive effect, and the genuine leather effect is strong.

Owner:JIANGSU BAOZE POLYMER MATERIAL

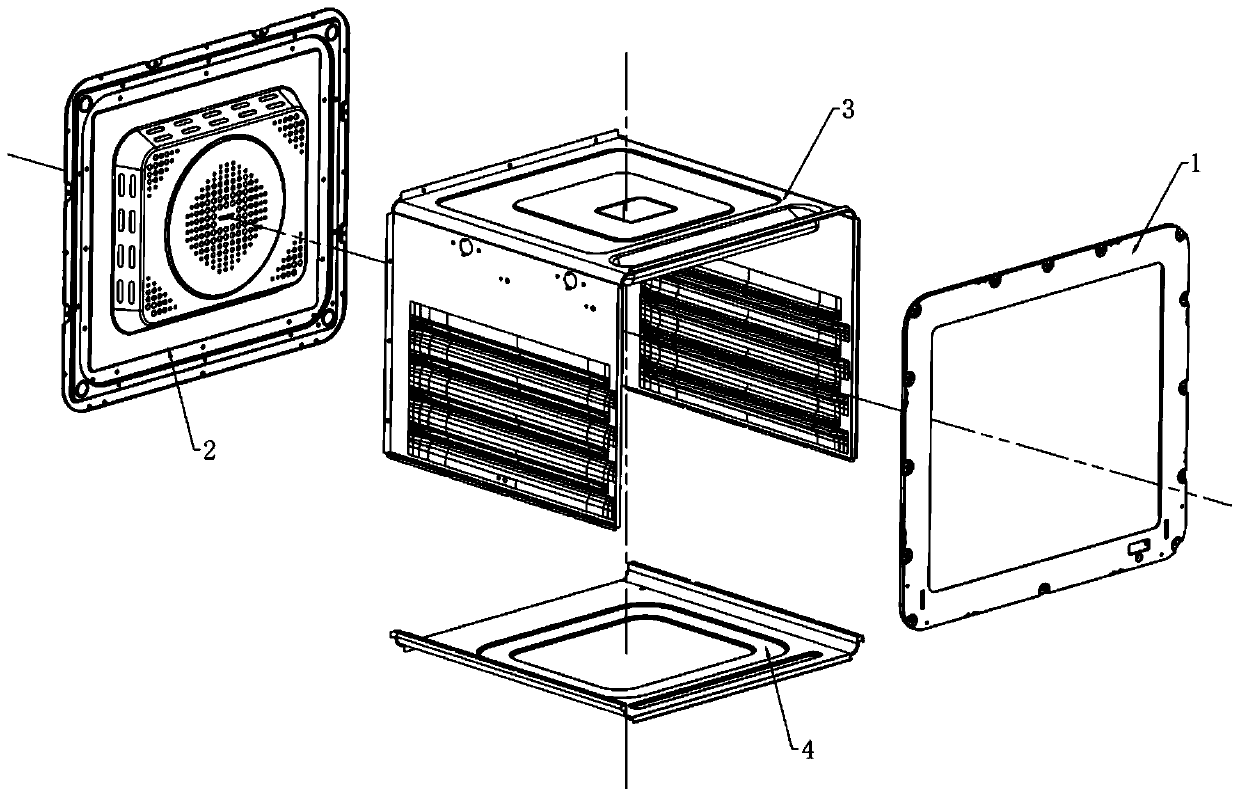

Electroplating cavity and manufacturing method

InactiveCN110747494AImprove corrosion resistanceImprove friction resistanceCooking-vessel materialsRoasters/grillsNichromeCopper

The invention relates to an electroplating cavity. The electroplating cavity comprises cavity blank and an electroplating layer coated on the cavity blank, wherein the electroplating layer consists ofthe following components in percentage by weight: 70%-90% of copper, 10%-20% of nickel, and 0.5%-5% of chromium. The invention further relates to a manufacturing method for the electroplating cavity,and the manufacturing method comprises the following steps: performing pre-plating treatment, plating nickel for bottoming, plating shinning copper for bottoming, plating acid copper for bottoming, plating shinning nickel, performing nickel sealing, plating chromium, dehydrating, roasting and packaging. The invention provides the electroplating cavity which does not change color after high-temperature roasting, strengthens corrosion resistance, friction resistance, glossiness and thermal reflection performance, and a manufacturing method thereof.

Owner:SHANGHAI CHUNMI ELECTRONICS TECH CO LTD

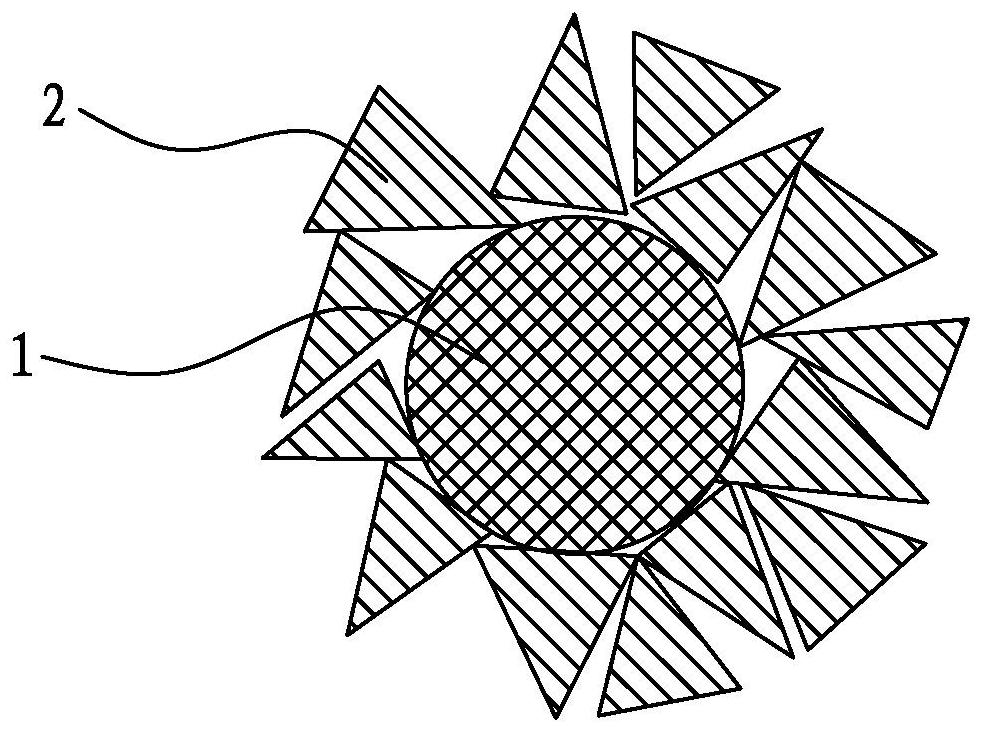

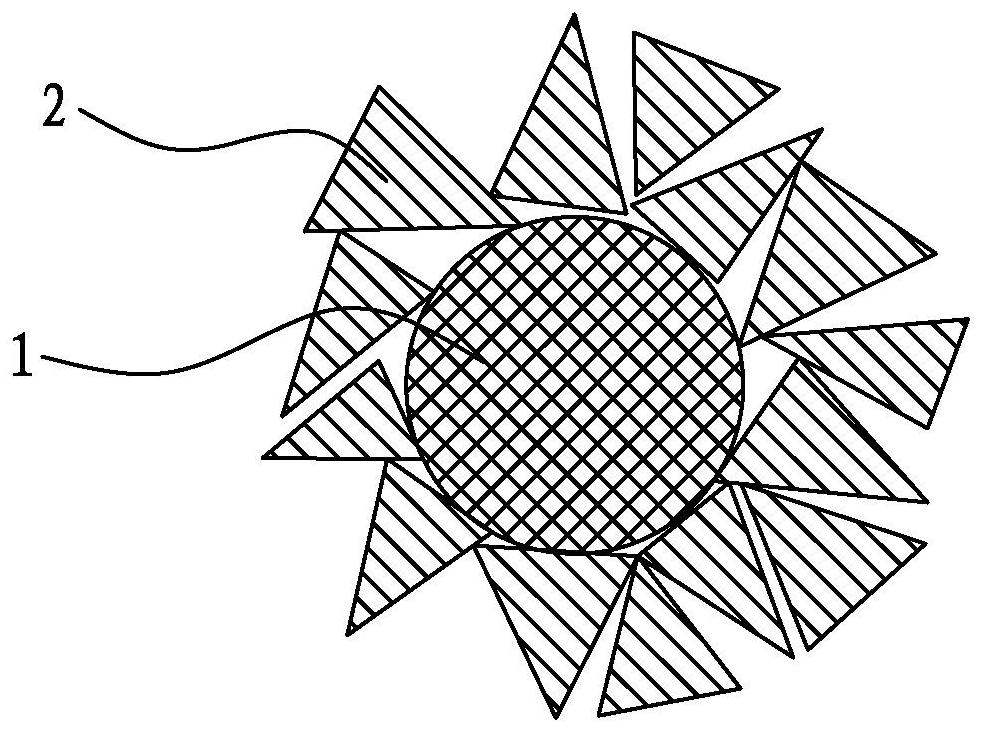

Flash polypropylene fiber and preparation method thereof

InactiveCN102154724AGood gloss effectHigh breaking strengthFilament/thread formingMonocomponent polyolefin artificial filamentSocial benefitsPolymer science

The invention provides a three-leaf flash polypropylene fiber. The flash polypropylene fiber is characterized in that: the section of the fiber is in a three-leaf shape; and a fiber forming process comprises the following steps of: adding sorbitol nucleating agent and flow aid dispersant into an isotactic polypropylene slice with melt index of 18 to 35 grams per 10 minutes in a ratio, performing high mixing and extraction melting, performing extrusion from three-leaf spinneret orifices at a low temperature, cooling and molding, stretching and sizing to obtain the polypropylene fiber with flash effect. The polypropylene fiber has obvious flash effect, large specific surface area, strong dirt absorption and soft handfeel, and the mechanical property of the polypropylene fiber is obviously improved; and industrialized production can be performed by using the conventional equipment and processes, and the polypropylene fiber has considerable economic and social benefits.

Owner:DALIAN POLYTECHNIC UNIVERSITY

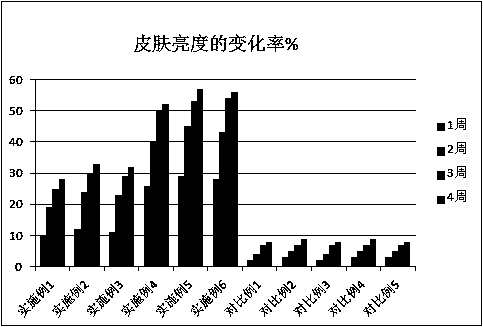

Scrubbing particles with exfoliating and complexion brightening functions and application thereof

InactiveCN108904375ABrightening effectGood gloss effectCosmetic preparationsToilet preparationsSkin complexionMedicine

The invention discloses scrubbing particles with exfoliating and complexion brightening functions. The scrubbing particles comprise the following compositions of, by weight, 1-10 parts of tabebuia impetiginosa barks, 1-10 parts of cedrus atlantica barks and 2-8 parts of hamamelis virginiana barks. The compositions of the scrubbing particles have the functions of exfoliating, melanosis removing, spot lightening, skin self-repair promoting, thereby finally improving rough skin and brightening complexion.

Owner:江西登云健康美业互联有限公司 +1

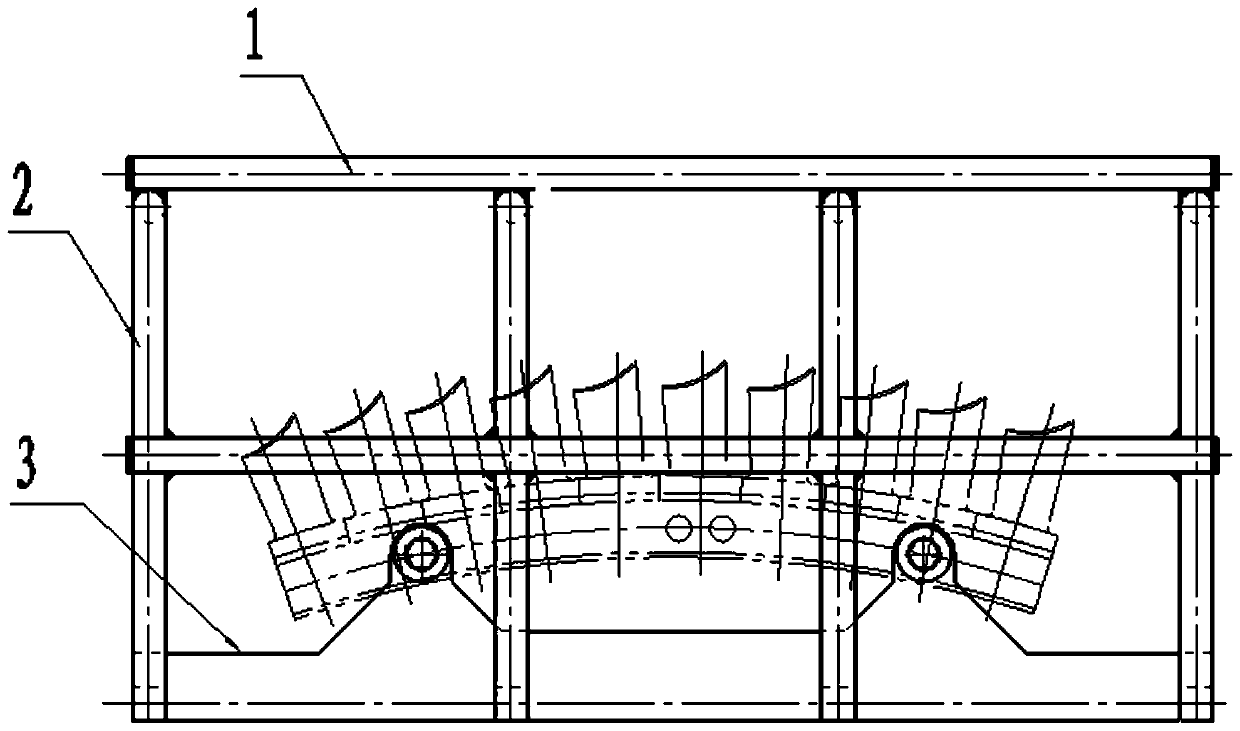

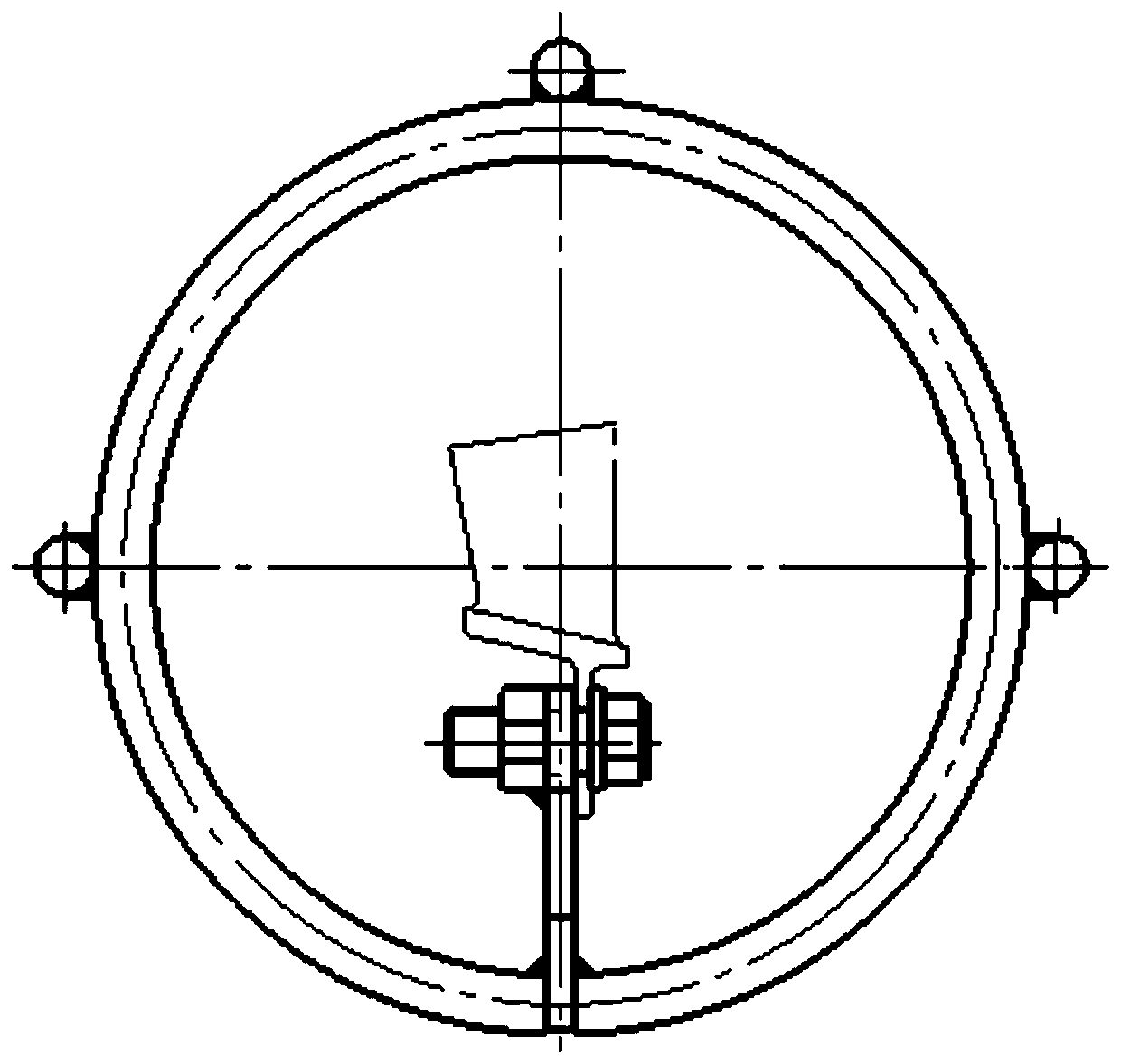

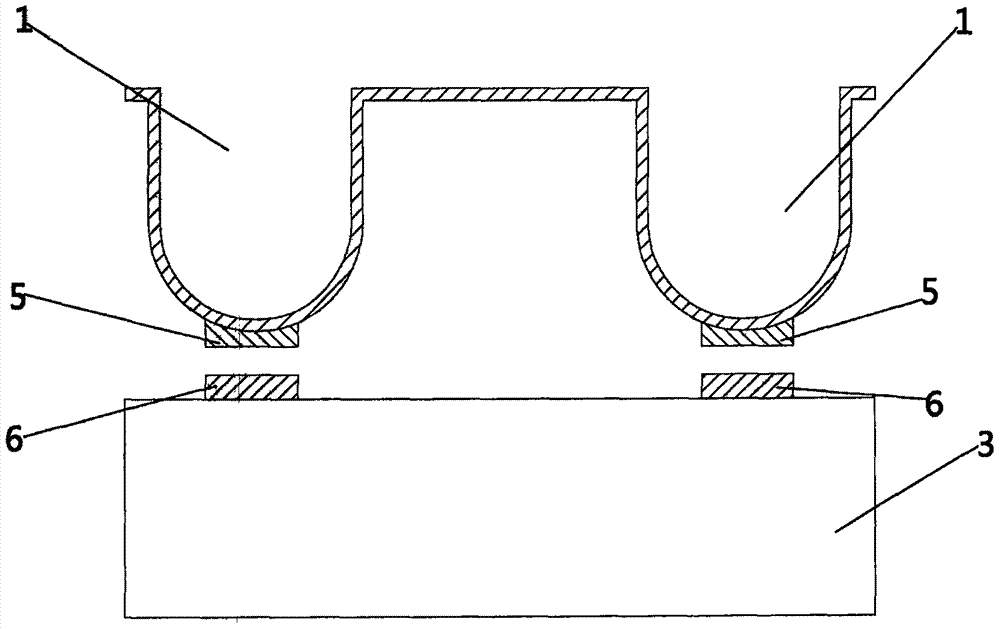

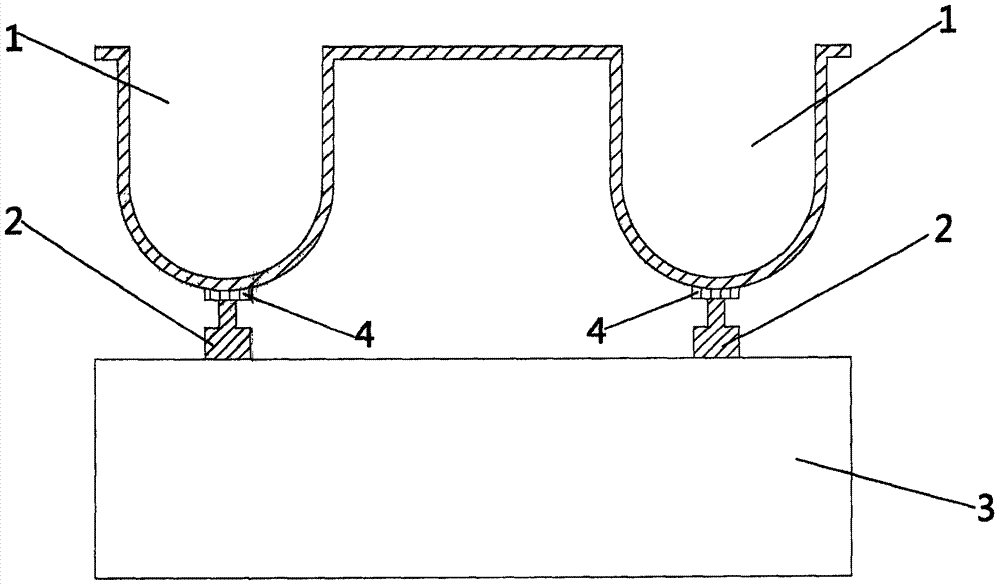

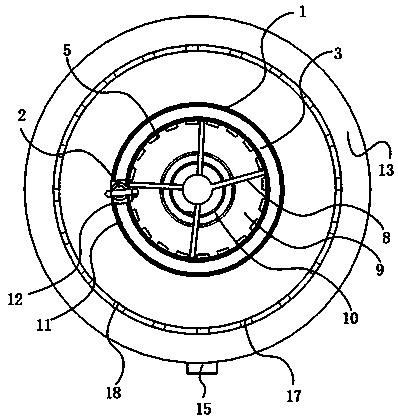

A New Vibration Finishing Machine

ActiveCN103331688BReduce impact forceNo "orange peel" phenomenonEdge grinding machinesPolishing machinesSurface finishEngineering

The invention discloses a novel vibrating burnisher, which comprises a base (1). A spring set (2) is arranged on the base (1). A working groove (3) is formed above the spring set (2). The novel vibrating burnisher is characterized by also comprising a first horizontal vibrating motor (4), a second horizontal vibrating motor (5) and a third horizontal vibrating motor (6), wherein the first horizontal vibrating motor (4) is arranged at the bottom of the working groove (3); and the second horizontal vibrating motor (5) and the third horizontal vibrating motor (6) are symmetrically arranged on the two sides of the working groove (3). Due to the adoption of a novel motor configuration, the novel vibrating burnisher can be used for performing surface burnishing treatment on a workpiece with higher surface finish, is wide in application range, and can be used for performing the surface burnishing treatment on a larger and softer workpiece with a complex structure.

Owner:HUZHOU XING XING ABRASIVE

Flash polypropylene fiber and preparation method thereof

InactiveCN102154724BGood gloss effectHigh breaking strengthFilament/thread formingMonocomponent polyolefin artificial filamentSocial benefitsPolymer science

The invention provides a three-leaf flash polypropylene fiber. The flash polypropylene fiber is characterized in that: the section of the fiber is in a three-leaf shape; and a fiber forming process comprises the following steps of: adding sorbitol nucleating agent and flow aid dispersant into an isotactic polypropylene slice with melt index of 18 to 35 grams per 10 minutes in a ratio, performing high mixing and extraction melting, performing extrusion from three-leaf spinneret orifices at a low temperature, cooling and molding, stretching and sizing to obtain the polypropylene fiber with flash effect. The polypropylene fiber has obvious flash effect, large specific surface area, strong dirt absorption and soft handfeel, and the mechanical property of the polypropylene fiber is obviously improved; and industrialized production can be performed by using the conventional equipment and processes, and the polypropylene fiber has considerable economic and social benefits.

Owner:DALIAN POLYTECHNIC UNIVERSITY

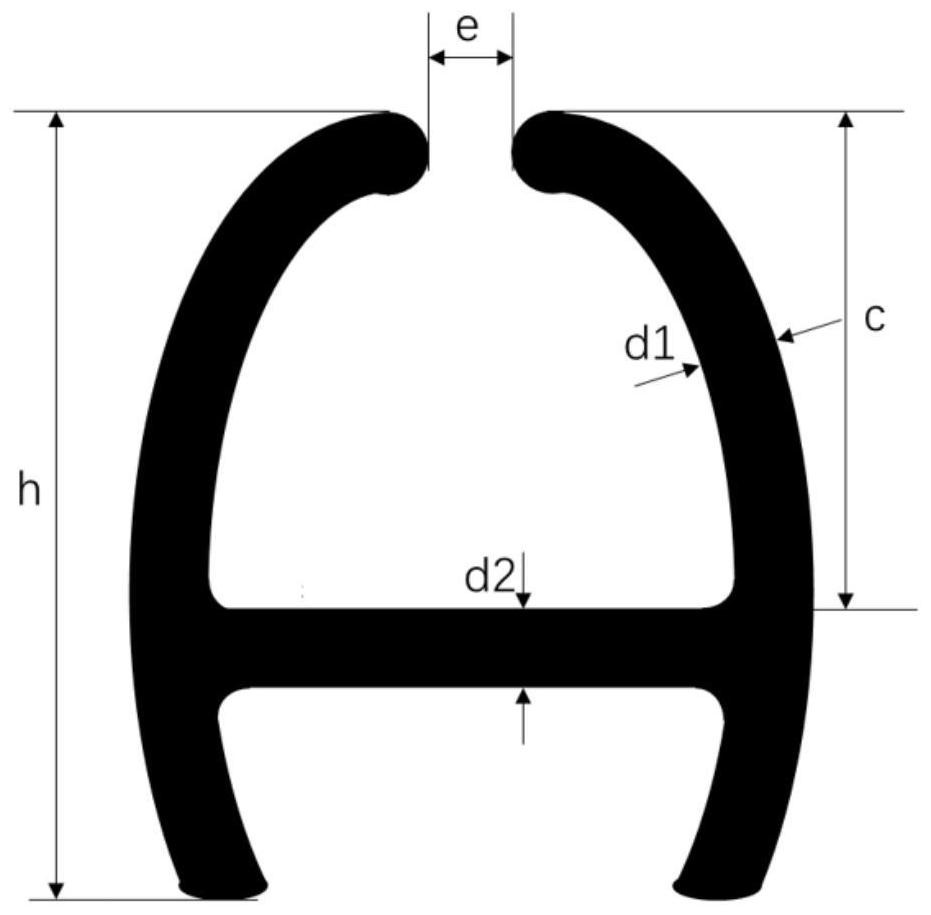

Warm-keeping moisture-conducting multifunctional nylon 6 fiber and preparation method thereof

InactiveCN112030250AEasy to processLow costElectroconductive/antistatic filament manufactureFilament/thread formingPolymer scienceSpinning

The invention relates to a warm-keeping and moisture-conducting multifunctional nylon 6 fiber and a preparation method thereof. The preparation method comprises the steps that nylon 6 serves as a rawmaterial, a spinneret plate with a similar H-shaped spinneret hole cross section is adopted for spinning, and the warm-keeping and moisture-conducting multifunctional nylon 6 fiber is prepared. The similar H shape is composed of a curve m, a curve n and a curve t, m and n are symmetrical, t is connected with m and n at the same time, the I ends of m and n are located on the same side, and the II ends of m and n are located on the same side; and the distance between the end I of m and the end I of n is 0.20-0.30 mm, and the distance between the end II of m and the end II of n is 0.35-0.50 mm. The cross section of the monofilament of the finally prepared warm-keeping moisture-conducting multifunctional nylon 6 fiber is similar to A shape, and the similar A shape is composed of a single bending curve and a curve located in the single bending curve. The process is simple, production can be achieved on the basis of an original device, the fibers can be endowed with excellent warm-keeping and moisture-conducting functions, and the method can be applied to the fields of clothing fibers, household textiles and the like.

Owner:SUZHOU UNIV

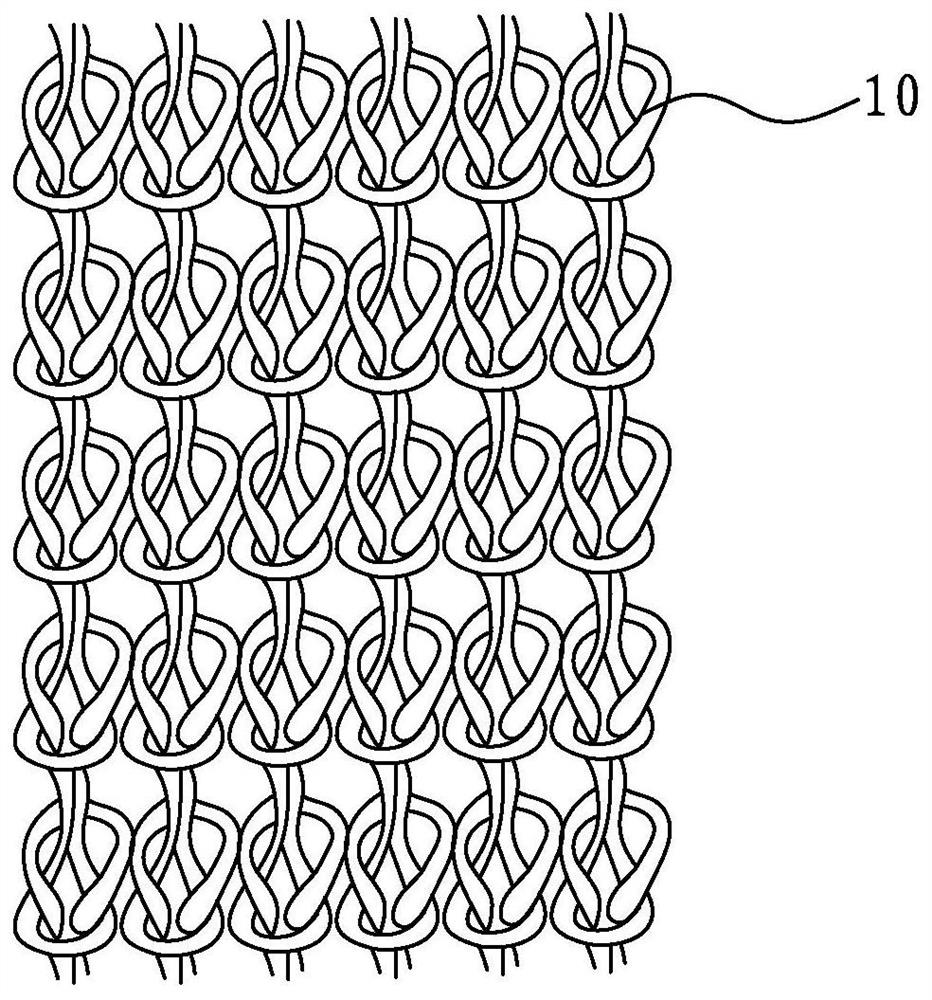

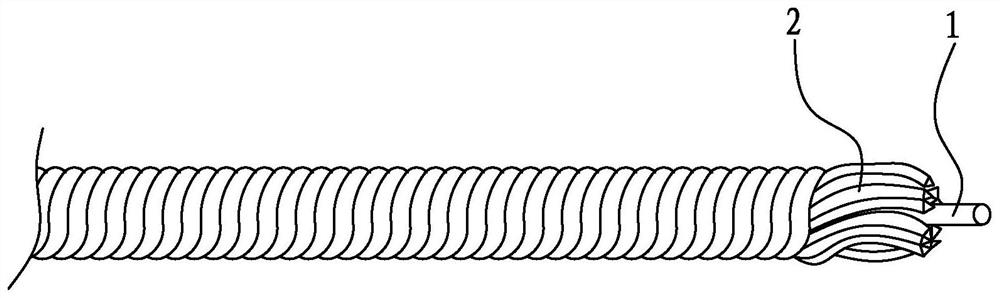

Yarn for manufacturing recyclable environment-friendly hotel slippers capable of being repeatedly washed by many times

The invention discloses a yarn for manufacturing recyclable environment-friendly hotel slippers capable of being repeatedly washed by many times. The yarn is manufactured from a spandex filament and multiple light polyamide yarns which cover the spandex filament. By virtue of the structure, the hotel slippers manufactured from the yarn have the advantages of being elastic, softer and wear-resisting, not pilling, preventing snag, being brighter in appearance, having striking gloss, being high in stiffness, having stiff effect and attractive flower-shaped appearance effect, being capable of being repeatedly washed by many times, being recyclable, being environmentally friendly and the like.

Owner:江苏征足者环保科技有限公司

Zoned material release finishing barrel and work method thereof

InactiveCN111113278APour moreAvoid reducing gloss effectAbrasive machine appurtenancesAbrasive blasting machinesStructural engineeringGrinding

The invention relates to a zoned material release finishing barrel which comprises a rough grinding barrel and further comprises a material release hopper, a storage bin, a material pump, material spraying valves, a PLC and a turnover mechanism. The storage bin is annularly arranged outside the rough grinding barrel, the material release hopper is erected above the storage bin and communicates with the storage bin, the material pump is arranged in the storage bin and electrically connected with the material spraying valves, and the multiple material spraying valves are annularly arranged on the inner wall of the rough grinding barrel; a baffle plate which divides the rough grinding barrel into a plurality of finishing areas is arranged in the rough grinding barrel, and the inner wall of the rough grinding barrel in each finishing area is provided with the corresponding material spraying valve; the two ends of a workpiece placing groove in each finishing area are respectively movably connected with the baffle plate through a pin shaft, one end of the turnover mechanism is connected with the baffle plate, and the other end of the turnover mechanism is connected with the bottom of each workpiece placing groove; and the PLC is electrically connected with the material pump and the turnover mechanism respectively. The workpiece with fixed weight can be controlled to be released in one finishing area, so that too many workpieces are prevented from being poured to reduce the finishing effect; and moreover, the workpiece is subjected to zoned finishing, so that excess abrasive is avoided while finishing efficiency is improved.

Owner:太仓市凯福士机械有限公司

Water PU polish processing agent for synthetic leather

The invention discloses a water PU polish processing agent for synthetic leather, which is composed of the raw materials in the following weight percent: 10-20% of water acrylic acid resin, 10-20% of water baking finish resin, 50-60% of water, 3-5% of modified organic silicon polymer, 0.5-1% of organic silicon flatting agent, 2-5% of organic silicon defoaming agent, and 0.5-2% of water PU thickening agent. The proportion of each components of the water PU polish processing agent for synthetic leather provided by the invention is scientific and reasonable, the components coordinate mutually and exert synergic effects, the polish processing agent has the advantages of good film forming property, firm bonding, solvent-resisting, cold-resisting, hydrolysis-resisting, thermal ageing-resisting of the coating. The finished product made by using the polish processing agent provided by the invention to process the surface of the synthetic leather has the feature of not influencing the originaleffect of the leather surface, after leather surface processing and polish processing, polishing surface effect on the prudent patterns of the leather surface is good and a contrast of polishing withmatting of the groove bottom is formed, thus having unique polish effect.

Owner:JIANGSU BAOZE POLYMER MATERIAL

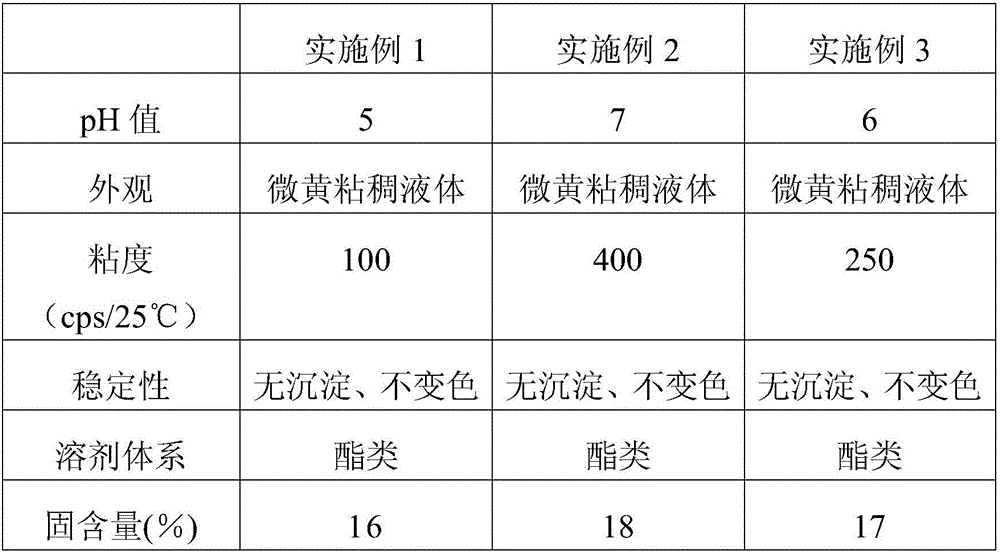

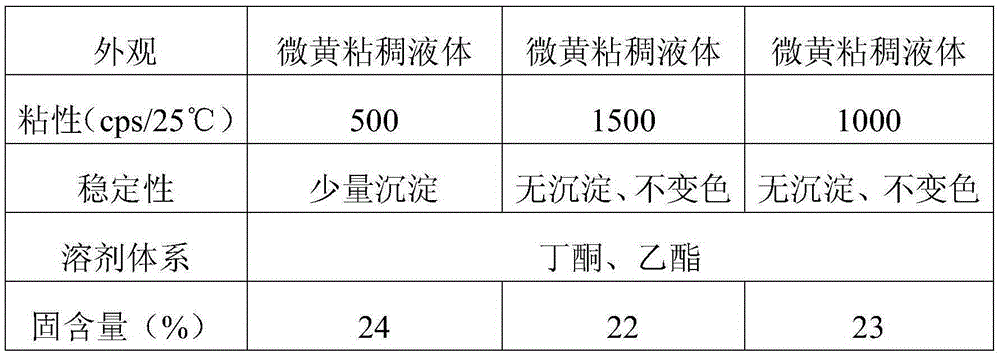

Acrylate table printing gravure ink and preparation method thereof

ActiveCN114752250AImprove adhesionHigh glossRotary stirring mixersTransportation and packagingPolymer scienceMeth-

The invention discloses acrylate table printing intaglio ink and a preparation method thereof, and relates to the technical field of intaglio ink, and the acrylate table printing intaglio ink is characterized by comprising a blend group and a dilution group in a weight part ratio of 5: (1-3), the blend group is prepared from the following components in parts by weight: 28 to 36 parts of acrylate emulsion, 16 to 26 parts of methyl cyclopentadiene dimer, 15 to 18 parts of color paste, 6 to 10 parts of antioxidant, 3 to 4 parts of penetrant, 2.0 to 2.6 parts of dispersing agent, 1.0 to 1.4 parts of photoinitiator and 0.6 to 0.8 part of polyacrylamide hydrochloride; and the dilution group comprises toluene, isopropanol, acetic ether and ethanol in a weight part ratio of 5: (3-3.5): (1-1.5): (0.5-1). Acrylate emulsion and methyl cyclopentadiene dimer are used as connecting materials, color paste, an antioxidant, a penetrating agent, a dispersing agent, a photoinitiator and polyallylamine hydrochloride are combined to form a stable blend group, and then the stable blend group is mixed with a dilution group composed of methylbenzene, isopropanol, acetic ether and ethyl alcohol; and the acrylate table printing gravure ink with remarkably improved adhesion and glossiness effects is obtained.

Owner:XIAMEN OUHUA IND

Hair care compositions

InactiveCN1313749AEasy to spreadGood conditionCosmetic preparationsHair cosmeticsScalpPolymer chemistry

The present invention provides a hair care composition comprising (a) a polysiloxane resin, wherein at least one substituent in the resin has delocalized electrons; and (b) C 1 -C 6 Aliphatic alcohols. The compositions of the present invention spread easily throughout the hair and deliver good conditioning and shine benefits while reducing stickiness and greasiness. In addition, the composition of the present invention provides a refreshing feeling to the scalp.

Owner:THE PROCTER & GAMBLE COMPANY

Polishing method of buttons

ActiveCN103639884BGood lookingReduce labor intensityPolishing machinesLapping machinesMaterials scienceHigh frequency

The invention discloses a polishing method for buttons. Putting high-frequency porcelain particles, buttons to be polished, silica sand powder, and chemical polishing agent in a double-connected eddy current polishing machine, adding water to immerse the above materials; buttons to be polished and high-frequency porcelain particles The mass ratio is 1:2-1:7, the addition amount of silica sand powder and chemical polishing agent is 2%-7% and 0.5%-1.5% of the total mass of solid material respectively; the size of the high-frequency porcelain particles is 2.5*8.0 mm or 3*3mm; set the first polishing time, the speed of the vortex polishing machine is 100-180 rpm; according to the first polishing effect, set the second polishing time, until the gloss of the button meets the requirements, clean the button . The button polishing method of the present invention has a polishing efficiency 3 to 4 times higher than that of the traditional method, the polishing effect is more stable, the production period is shortened, the labor cost and the labor intensity of the employees are reduced, and the produced button has an excellent appearance .

Owner:广东康派环创科技有限公司

Polyphenylene sulfide composition and preparation method and application thereof

The invention discloses a polyphenylene sulfide composition and a preparation method and application thereof. The polyphenylene sulfide composition comprises the following components in parts by weight: 35-50 parts of polyphenylene sulfide; 3-8 parts of glass fiber; 25-40 parts of calcium carbonate; 20-35 parts of a filler; and 0.1-1 part of a coupling agent. The glass fiber, the calcium carbonate and the fibrous or flaky filler are added into the polyphenylene sulfide resin and are matched with one another, meanwhile, a certain amount of coupling agent is added, so that the rigidity of the material can be effectively improved, a relatively good glossiness effect is kept, and the prepared polyphenylene sulfide material has excellent tensile strength and bending strength, is high in glossiness, and can meet the higher requirements on the material strength in the miniaturization and thin-wall development process of the automobile lamp reflecting cover.

Owner:KINGFA SCI & TECH CO LTD

A kind of skin polishing treatment agent for synthetic leather and preparation method thereof

The invention relates to a luster improving polishing treatment agent for synthetic leather and a preparation method thereof. The treatment agent comprises alkyd resin, nitro-cotton, butanone, butyl ether, ethyl ester, silica extinction powder, organic modified methyl phenyl silicone oil and a dispersing agent. The luster improving polishing treatment agent for synthetic leather is a novel material for back-section printing of synthetic leather. By application of the treatment agent, the leather surface of synthetic leather is natural in gloss, clear in color and luster and high in temperature resistance and can be subjected to embossing, and polished synthetic leather has a good surface brightening effect, a good leather effect and excellent comprehensive effects.

Owner:浙江宝泽高分子材料有限公司

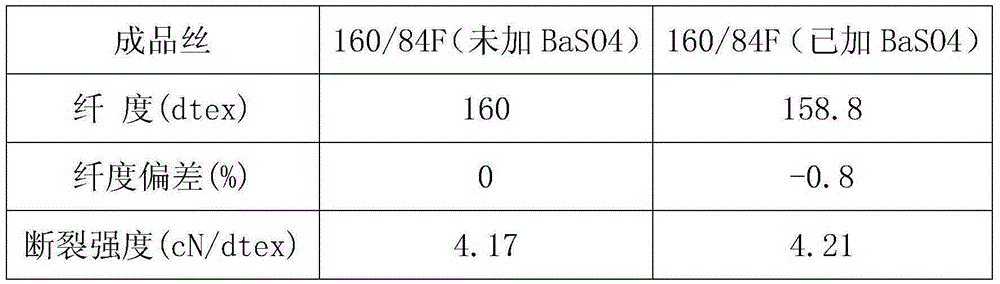

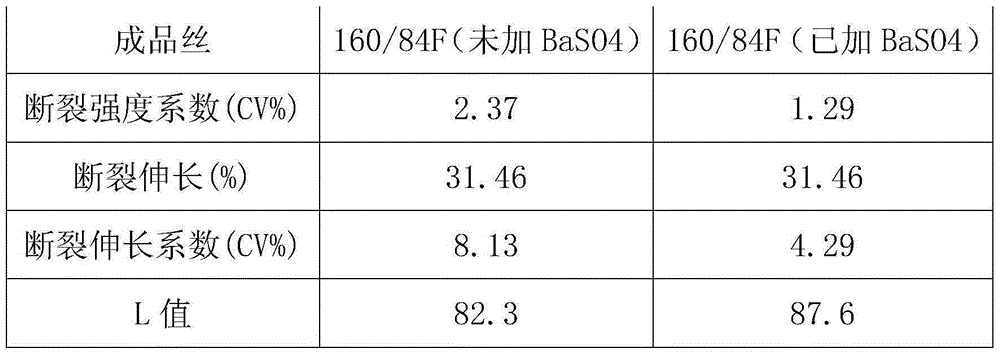

A kind of preparation method of polymerized micro-modified bright polyester fiber

ActiveCN103290507BIncrease the amount of controlSimple production processArtificial filament heat treatmentMelt spinning methodsPolyesterFiber

The invention discloses a method for producing chemical fibers, in particular discloses a preparation method of super bright polyester fibers, and aims to provide a preparation method of polymerized micro-amount modified super bright polyester fibers which are bright in luster, excellent in performance and good in abrasion resistance. By adopting the preparation method, a woven fabric has good hand feeling, excellent moisture penetrability and air permeability, bright appearance and excellent luster, and can be used for scarves, pajamas, sweaters, woolen sweaters, shell fabrics needing a flash effect and the like.

Owner:XINFENGMING GRP HUZHOU ZHONGSHI TECH CO LTD

Recyclable environment-friendly hotel slipper fabric capable of being washed repeatedly

The invention discloses a recyclable environment-friendly hotel slipper fabric capable of being washed repeatedly, the fabric is formed by spinning yarns, each yarn is formed by spinning a spandex filament and a bundle of lustrous polyamide yarns containing a plurality of yarns, and the plurality of lustrous polyamide yarns wrap the spandex filament; by means of the structure, hotel slippers madeof the fabric have the advantages of having elasticity, and being more flexible, resistant to abrasion, free of pilling and snagging, brighter in appearance, glossy, attractive, high in stiffness, attractive in body bone effect and flower shape appearance effect, capable of being washed repeatedly, recyclable, environmentally friendly and the like.

Owner:江苏征足者环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com