Warm-keeping moisture-conducting multifunctional nylon 6 fiber and preparation method thereof

A multi-functional, nylon technology, applied in fiber processing, fiber chemical characteristics, conductive/antistatic filament manufacturing, etc., can solve the problems of warmth retention, moisture permeability, lightness and lightness, etc., to improve gloss effect and Hand feeling, simple production process and simple processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

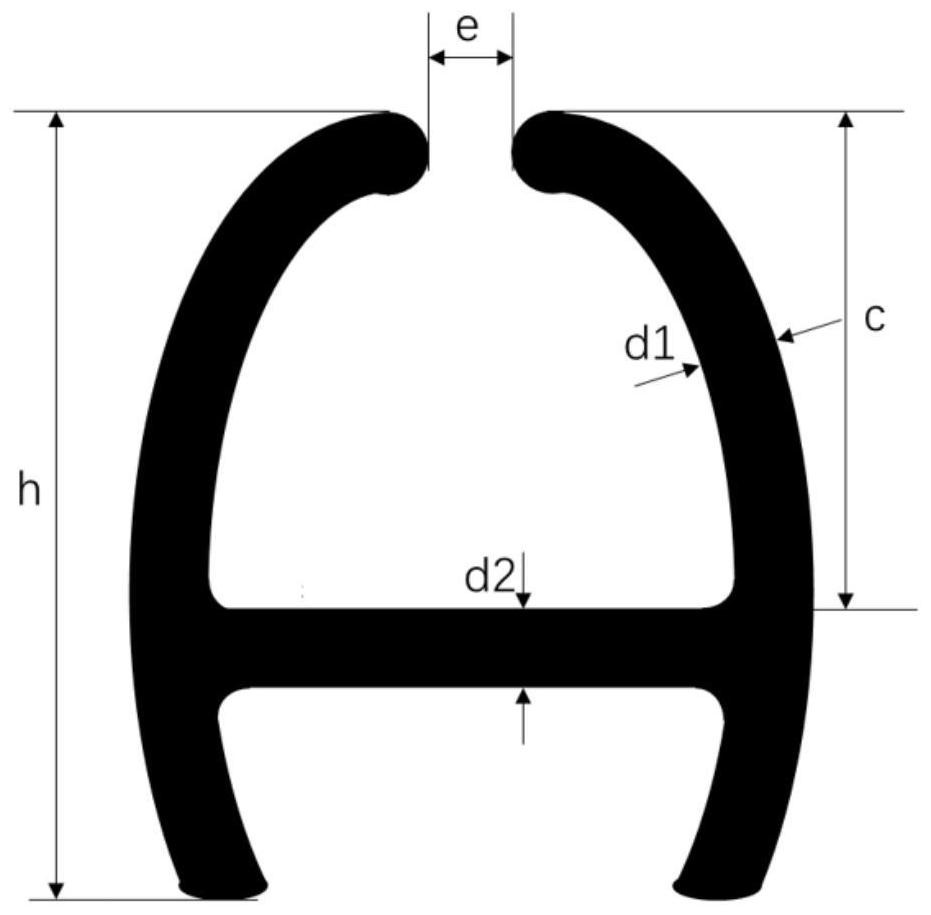

Image

Examples

Embodiment 1

[0040] A method for preparing warm and moisture-conducting multifunctional nylon 6 fibers, the steps are as follows:

[0041] (1) Raw material allocation;

[0042] At a temperature of 80°C, caprolactam, terephthalic acid and deionized water were mixed, wherein relative to the caprolactam, the amount of deionized water added was 1 wt%, and the amount of terephthalic acid added was 0.1 wt%;

[0043] (2) Ring-opening reaction;

[0044] Transfer the mixture obtained in step (1) to a ring-opening kettle for ring-opening reaction. The temperature of the ring-opening reaction is 230°C, the pressure is 0.1MPa, and the time is 3h;

[0045] (3) polycondensation reaction;

[0046] The ring-opening reaction product obtained in step (2) was subjected to polycondensation reaction to obtain nylon 6. The temperature of the polycondensation reaction was 230°C, the pressure was -0.1MPa, and the time was 3h;

[0047] (4) Nylon 6 is mixed with functional components, the content of functional c...

Embodiment 2

[0070] A method for preparing warm and moisture-conducting multifunctional nylon 6 fibers, the steps are as follows:

[0071] (1) Raw material allocation;

[0072] At a temperature of 95°C, caprolactam, terephthalic acid and deionized water were mixed, wherein relative to the caprolactam, the amount of deionized water added was 2 wt%, and the amount of terephthalic acid added was 0.2 wt%;

[0073] (2) Ring-opening reaction;

[0074] Transfer the mixture obtained in step (1) to a ring-opening kettle for ring-opening reaction. The temperature of the ring-opening reaction is 238°C, the pressure is 0.2MPa, and the time is 5h;

[0075] (3) polycondensation reaction;

[0076] The ring-opening reaction product obtained in step (2) was subjected to polycondensation reaction to obtain nylon 6. The temperature of the polycondensation reaction was 240° C., the pressure was 0 MPa, and the time was 5 hours;

[0077] (4) Nylon 6 is mixed with functional components, the content of functio...

Embodiment 3

[0084] A method for preparing warm and moisture-conducting multifunctional nylon 6 fibers, the steps are as follows:

[0085] (1) Raw material allocation;

[0086] At a temperature of 108°C, mix caprolactam, terephthalic acid and deionized water, wherein relative to caprolactam, the amount of deionized water added is 2.5wt%, and the amount of terephthalic acid added is 0.25wt% ;

[0087] (2) Ring-opening reaction;

[0088] Transfer the mixture obtained in step (1) to a ring-opening kettle for ring-opening reaction. The temperature of the ring-opening reaction is 245°C, the pressure is 0.5MPa, and the time is 6h;

[0089] (3) polycondensation reaction;

[0090] The ring-opening reaction product obtained in step (2) was subjected to a polycondensation reaction to obtain nylon 6. The temperature of the polycondensation reaction was 255° C., the pressure was 0.01 MPa, and the time was 9 hours;

[0091] (4) Nylon 6 is mixed with the functional component, the content of the func...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com