Rapid installation method of high-rise steel structure truss roof

An installation method and steel truss technology, which is applied to truss structures, roofs, truss beams, etc., can solve the problems of long overall construction period, difficulty in hoisting steel trusses on high-rise roofs, and the inability to use large hoisting machines and multiple lifting machines , to achieve the effect of reducing the difficulty of hoisting, saving the construction period and saving the project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

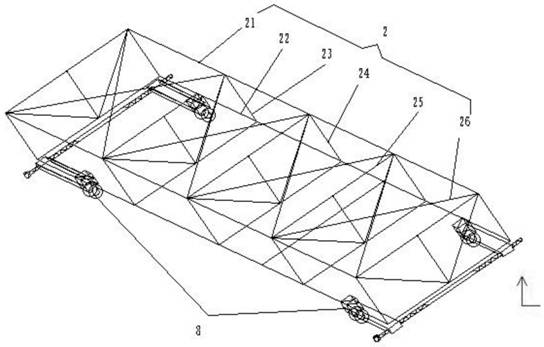

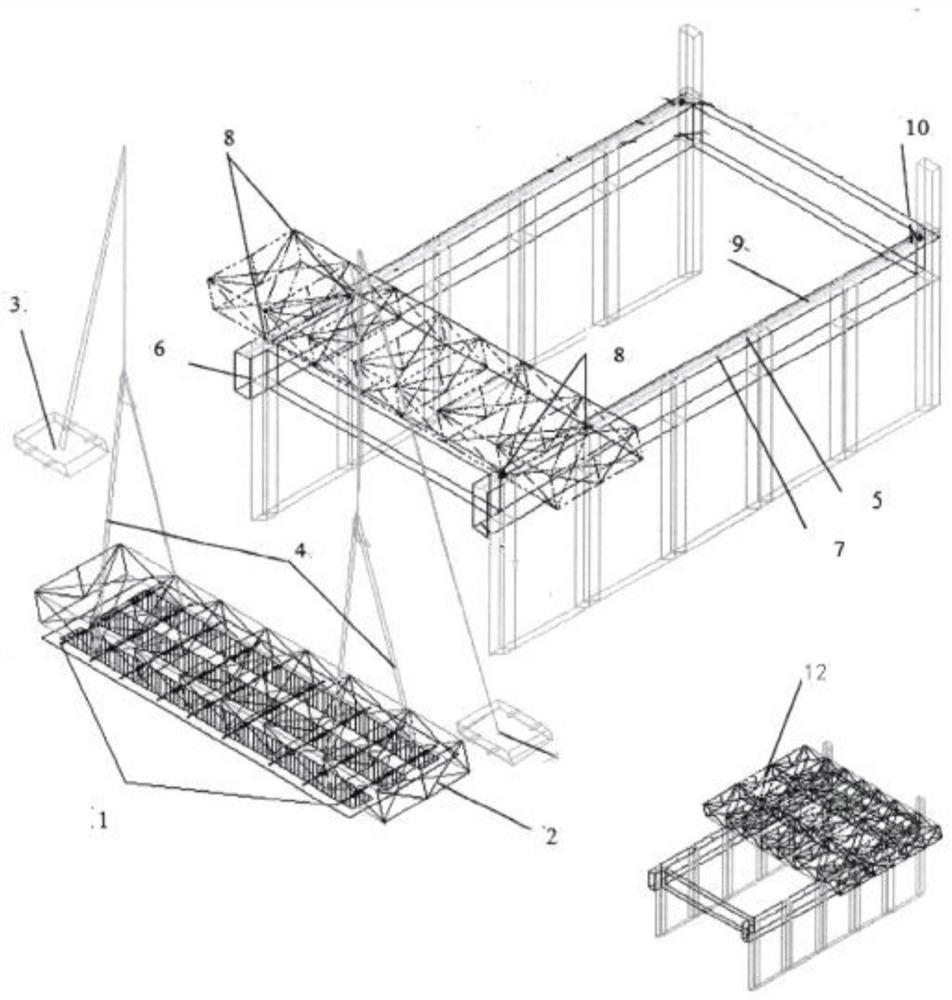

[0043] A rapid installation method for a high-rise steel structure truss roof, including a support system 1, a steel truss 2, a hoisting device 3, a sling 4, a sliding track 5, a concrete roof truss beam 6, and an embedded part 7 for fixing the sliding track 5, Transport trolley 8, traction rope 9, traction device 10, unloading device 11 and reserved filling area 12, wherein the single group steel truss 2 includes upper chord member 21, lower chord member 22, connecting upper chord member 21 and lower chord member 22 Between the vertical rods 23, the diagonal braces 24, the main trusses 25, and the horizontal rods 26 connecting the main trusses 25, all the connecting points of the rods are fixed by welding.

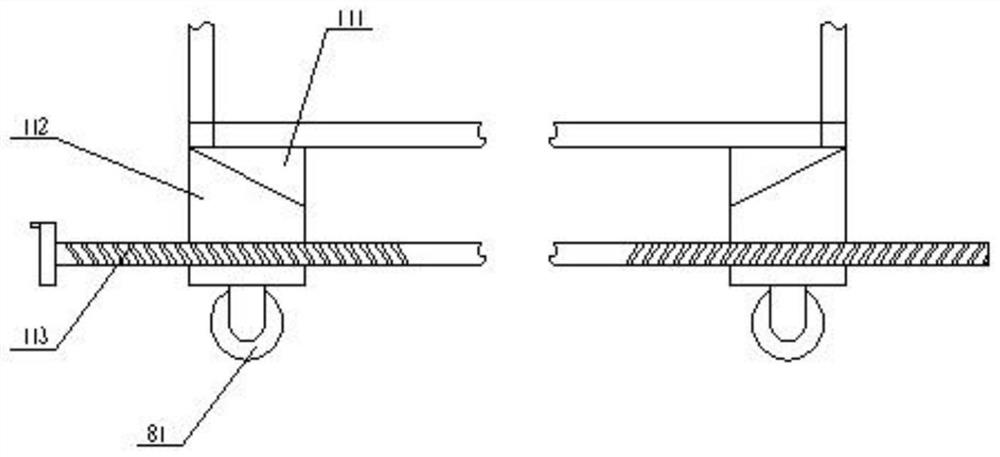

[0044]The transport trolley 8 includes four sets of wheel assemblies 81 that are adapted to the sliding track 5, and the four sets of wheel assemblies 81 are all movably installed on the bottom of the steel truss 2, and the unloading device 11 includes a fixing piece 111, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com