Fresh milk closed conveying system and corresponding conveying method

A technology of airtight transportation and fresh milk, which is applied in the direction of cleaning methods using liquids, pipeline systems, separation methods, etc., which can solve problems such as high cost, reduced freshness of raw milk, and improvement of product quality, so as to save transportation costs and labor costs , reduce the possibility of contamination, and ensure the effect of no loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

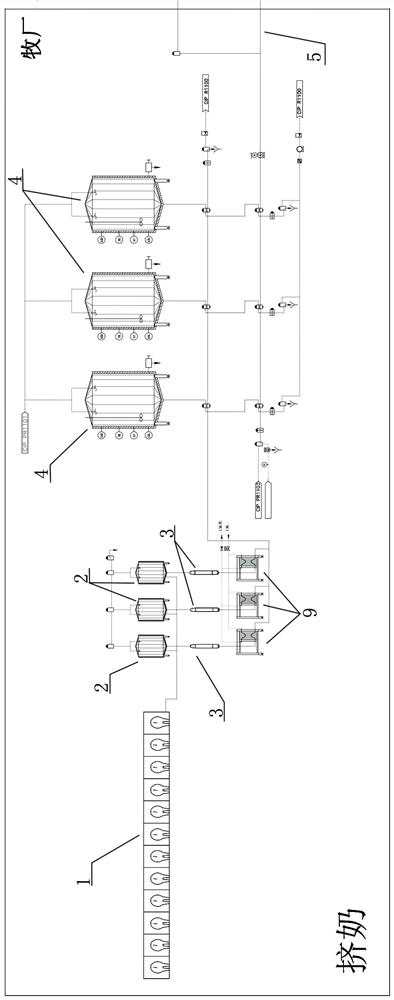

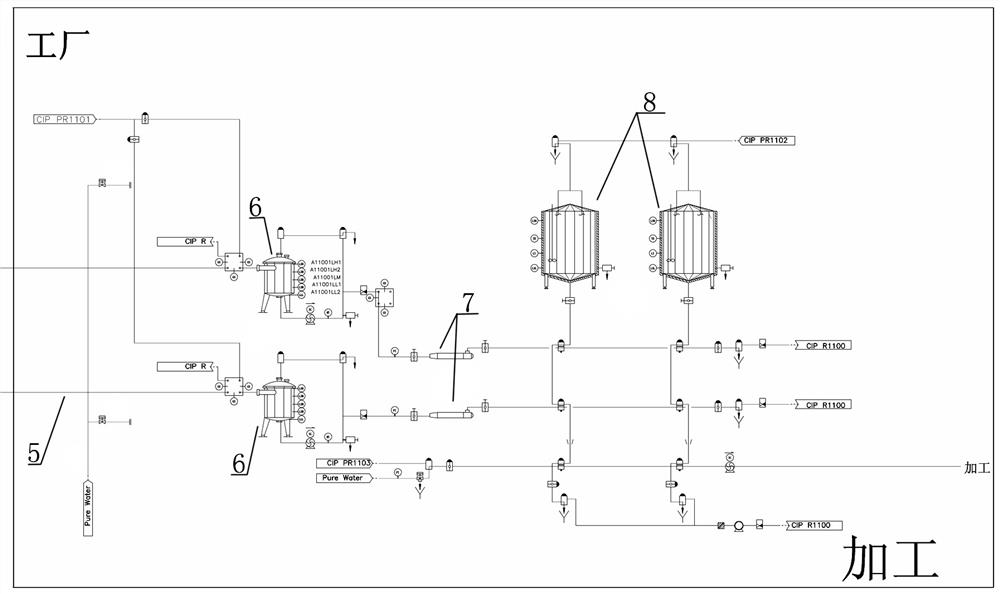

[0060] Example 1 A fresh milk closed delivery system

[0061] This embodiment includes a central control device, a conveying device and an online cleaning device.

[0062] The central control device includes PLC programmable logic controller, central control computer with built-in human-computer interaction software, I / O interface, signal conversion module, signal transmission module and field control cabinet;

[0063] The central control computer passes the signal transmission module, the signal conversion module and the PLC programmable logic controller. The operation signal sent by the central control computer is sent to the signal conversion module through the signal transmission module, and the signal conversion module converts the operation signal and sends it to the PLC programmable logic controller. controller;

[0064] The I / O interface of the PLC programmable logic controller is connected to the field control through the signal conversion conversion module and the s...

Embodiment 2

[0070] Example 2 A fresh milk airtight delivery method

[0071] This embodiment is implemented using Embodiment 1, including a milking process and a milk collection process, wherein the milking process includes the following steps in sequence:

[0072] A1. The operator sends a milking operation signal through the human-computer interaction software in the central control computer;

[0073] A2. The milking operation signal is transmitted to the signal conversion module through the signal transmission module, and the converted milking operation signal is transmitted to the PLC programmable logic controller through the signal transmission module;

[0074] A3. The PLC programmable logic controller recognizes the milking operation signal and invokes and executes the automatic milking program, and then outputs the milking command to the signal conversion module through the I / O interface, and the converted milking command is transmitted to the on-site control through the signal trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com