Tailor-welding type large-caliber steel lamp pole

A large-diameter, steel technology, applied in the field of tailor-welded large-diameter steel light poles, can solve the problems of light pole protection damage, equipment installation difficulties, and complex production processes, etc., to reduce the difficulty of forming, simple and reliable structure, and guarantee The effect of welding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

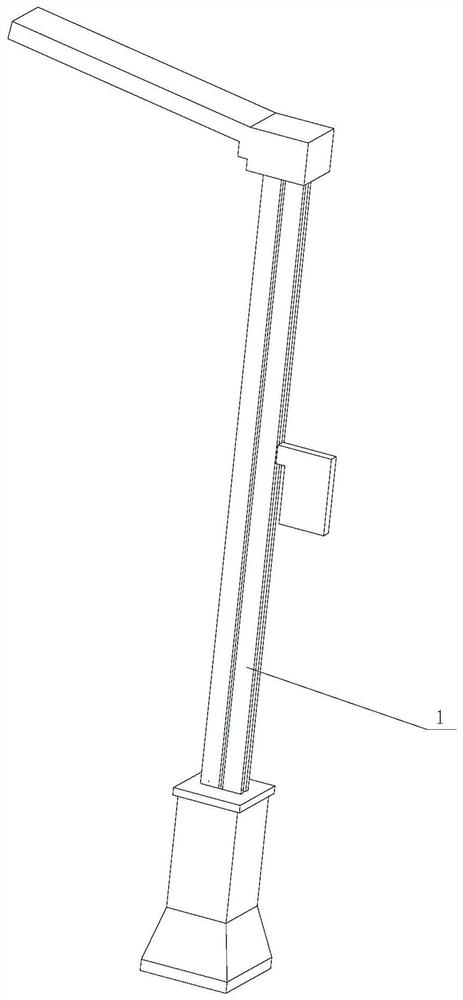

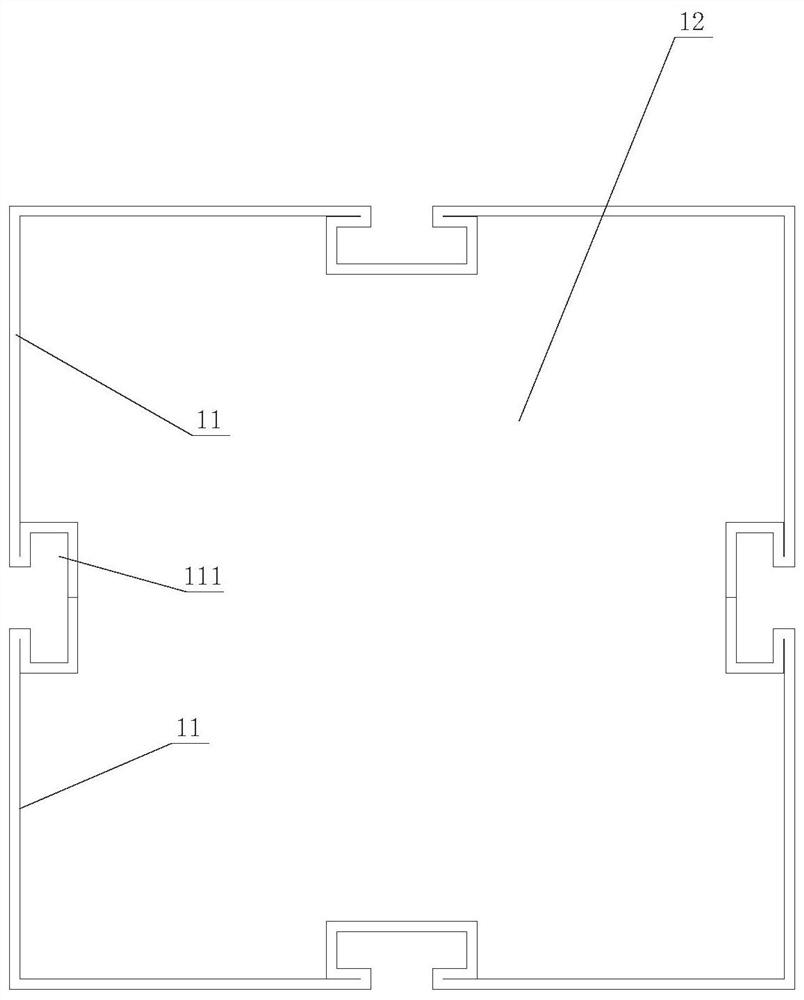

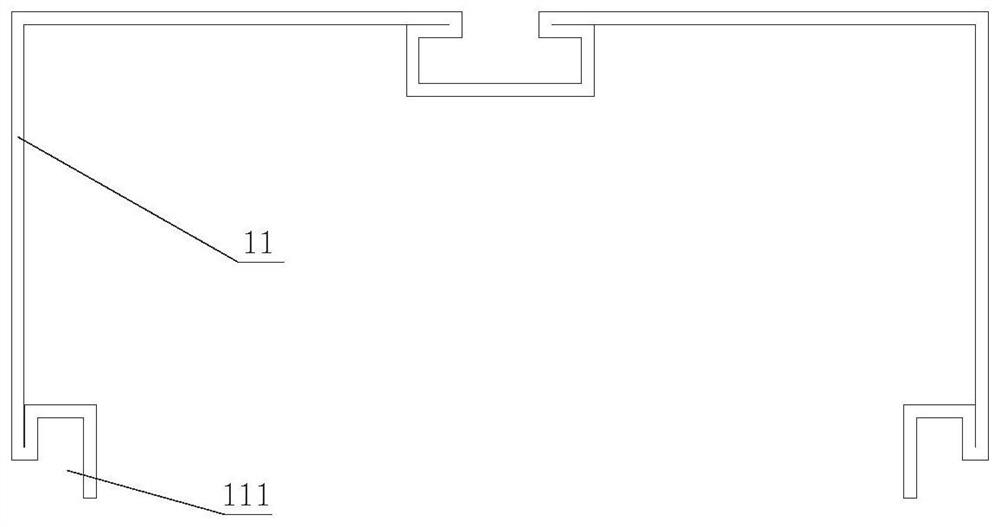

[0045] Figure 1 to Figure 4 It shows the first embodiment of the tailor-welded large-diameter steel light pole of the present invention, the large-diameter steel light pole includes a steel rod 1, and the steel rod 1 includes at least two steel opening profiles 11, Each steel opening profile 11 is surrounded and spliced to form a steel rod 1, and the steel rod 1 has a large opening 12, at least one steel opening profile 11 is bent and formed with a functional groove 111, and each steel opening profile 11 A bevel 13 is reserved at the enclosed joint, and each steel opening profile 11 is welded and connected at the bevel 13. The light pole involves a large diameter and is formed by steel profiles, that is, at least two steel opening profiles 11 are used to bend into a unit block, and then each steel opening profile 11 is enclosed, and the grooves reserved at the enclosing nodes 13 places are welded and connected to form a steel rod 1, and a functional groove 111 is formed on...

Embodiment 2

[0050] Figure 5 to Figure 7It shows the second embodiment of the tailor-welded large-diameter steel light pole of the present invention. The large-diameter steel light pole is basically the same as that of Embodiment 1, and the only difference is that in this embodiment, each steel opening profile 11 is inconsistent in size. The size of the steel opening profile 11 is set to be inconsistent, so that the strength of the large-size steel opening profile 11 in the steel bar 1 is higher, which is beneficial to improving the overall strength and performance.

Embodiment 3

[0052] Figure 8 to Figure 10 It shows the third embodiment of the tailor-welded large-diameter steel light pole of the present invention. The large-diameter steel light pole is basically the same as the first embodiment, the only difference is: in this embodiment, the steel opening profile 11 The cross-section is set in an arc shape, and each steel opening profile 11 is surrounded and welded to form a circular steel rod 1 . The circular steel rod 1 has a simple and reliable structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com