Large-plane vapor chamber of composite wick

A liquid absorbing core and soaking plate technology, which is applied in indirect heat exchangers, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of poor heat transfer performance, insufficient steam flow space, and insufficient structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

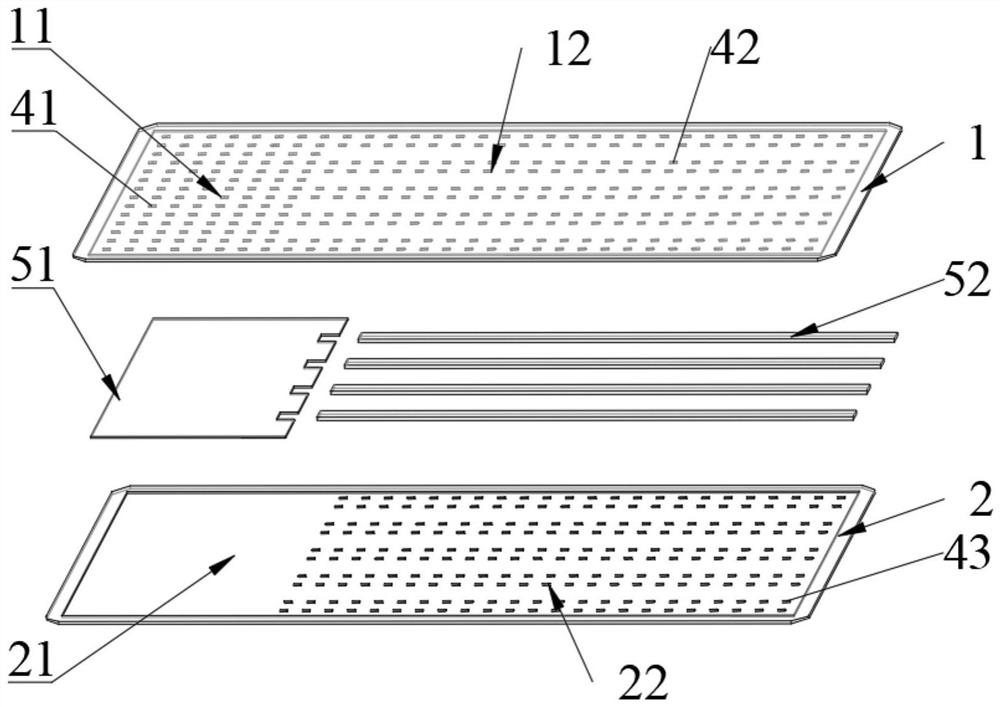

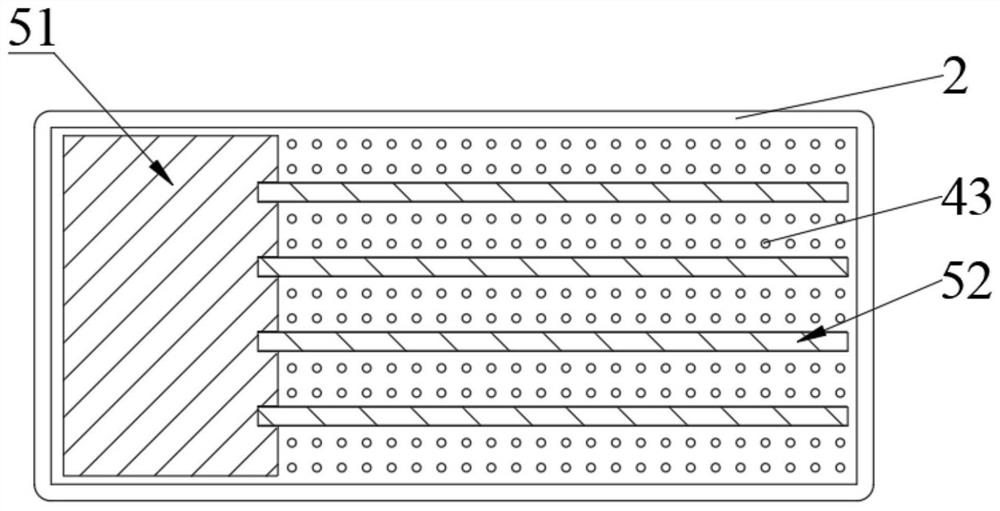

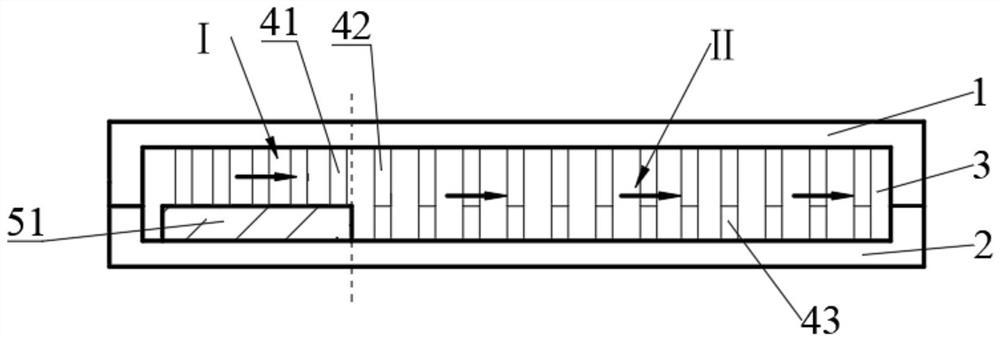

[0029] A large flat vapor chamber of a composite liquid-absorbing core, comprising an upper cover plate 1 and a lower cover plate 2 that are sealed and connected around the periphery to form a sealed working medium cavity 3, the sealed working medium cavity 3 is in a vacuum state, and is filled with liquid Working medium, the upper cover plate 1 is provided with a first area 11 and a second area 12, wherein the first area 11 is near the evaporation end, and is provided with a number of densely arranged first support columns 41, and the second area 12. A number of sparsely arranged second support pillars 42 are provided, wherein a second liquid-absorbing core 52 is placed in the gap between the second support pillars 42;

[0030] The lower cover plate 2 is provided with a third area 21 and a fourth area 22, wherein the size of the third area 21 corresponds to the first area 11, and is used to place the first liquid-absorbent core 51; the size of the fourth area 22 Corresponding...

Embodiment 2

[0038] A large flat vapor chamber of a composite liquid-absorbing core, comprising an upper cover plate 1 and a lower cover plate 2 that are sealed and connected around the periphery to form a sealed working medium cavity 3, the sealed working medium cavity 3 is in a vacuum state, and is filled with liquid Working medium, the upper cover plate 1 is provided with a first area 11 and a second area 12, wherein the first area 11 is near the evaporation end, and is provided with a number of densely arranged first support columns 41, and the second area 12. A number of sparsely arranged second support pillars 42 are provided, wherein a second liquid-absorbing core 52 is placed in the gap between the second support pillars 42;

[0039] The lower cover plate 2 is provided with a third area 21 and a fourth area 22, wherein the size of the third area 21 corresponds to the first area 11, and is used to place the first liquid-absorbent core 51; the size of the fourth area 22 Corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com