Multi-axis linkage metal wire torsion test device

A metal wire and torsion test technology, which is applied in the direction of measuring devices, testing the strength of materials by applying repetitive force/pulsation force, and analyzing materials, can solve the problems of poor adaptive ability of the test system, no automatic counting device, and low test efficiency. , to achieve the effect of improving test accuracy and repeatability, reducing human manual errors, and reducing test cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

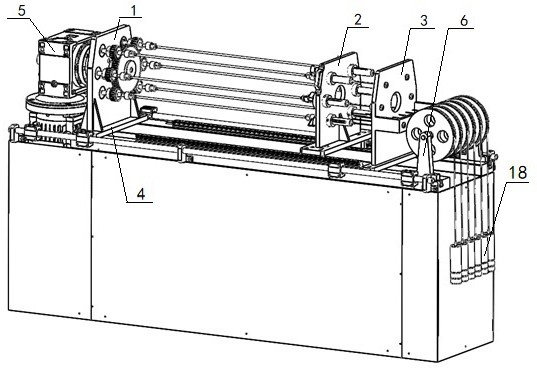

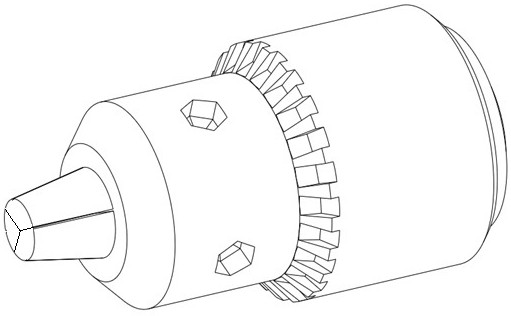

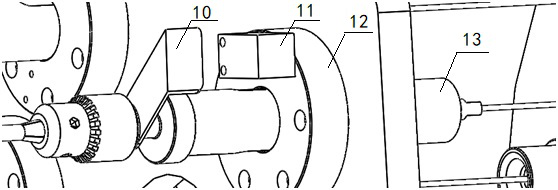

[0024] Example figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, this embodiment provides a multi-axis linkage metal wire torsion test device, including a PC host computer, a safety cover arranged on a frame, a T-shaped platen, a PLC controller, a gear motor 5, a servo driver, and a servo motor and the transmission mechanism, the controller controls the speed and angle of the deceleration motor through the servo motor, the deceleration motor is connected to the transmission mechanism 1, which also includes a position fixing seat 4, a constant tension tensioning device 6, a sliding end steel wire clamping module 2 and a connecting rope positioning module 3. The transmission mechanism 1 includes a driving gear 7 and 6 driven gears 8. The driving gear 7 is equidistantly and symmetrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com