Vacuum noise separation system for lithography equipment

A technology of isolation system and lithography equipment, applied in the field of vacuum noise isolation system, can solve the problems of inability to use rubber seal, intolerant of baking outgassing, low reliability, etc., to improve accuracy, reduce noise and noise, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

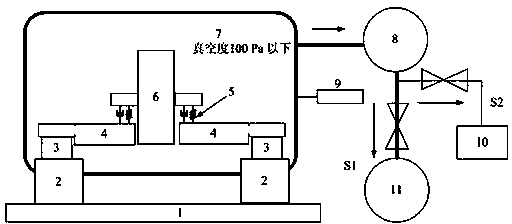

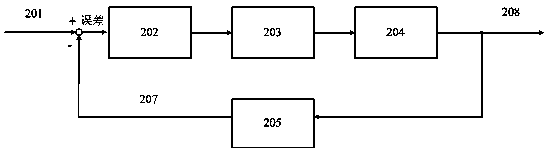

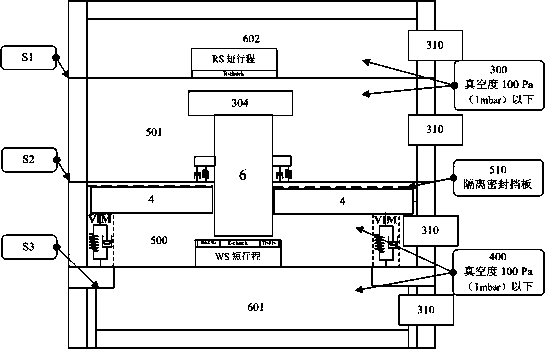

[0033] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The technical terms that will be used in the present invention are as follows:

[0034] Light source system, Source, SO

[0035] The terms "radiation" and "beam" as used herein encompass all types of electromagnetic radiation including: ultraviolet (UV) radiation (e.g. having a wavelength of about 365, 248, 143, 157 or 126 nm), and particle beams, such as ion beams or electron beam.

[0036] Illumination System, Illuminator, ILL

[0037] The illumination system may include various types of optical components, such as refractive, reflective, magnetic, electromagnetic, electrostatic, or other types of optical elements, or combinations of all of these elements, to direct, shape, or steer the radiation beam .

[0038] The illuminator ILL receives the radiation beam emitted from the radiation source SO. The source and the lithographic apparatus ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com