Machine tool cutter vibration monitoring and analyzing method based on artificial intelligence and big data

A technology of artificial intelligence and analysis methods, applied in manufacturing tools, neural learning methods, electrical digital data processing, etc., can solve the problems of poor versatility and applicability, high signal-to-noise ratio, and low precision of characteristic signal processing, and achieve installation and deployment Convenience and simple feature extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

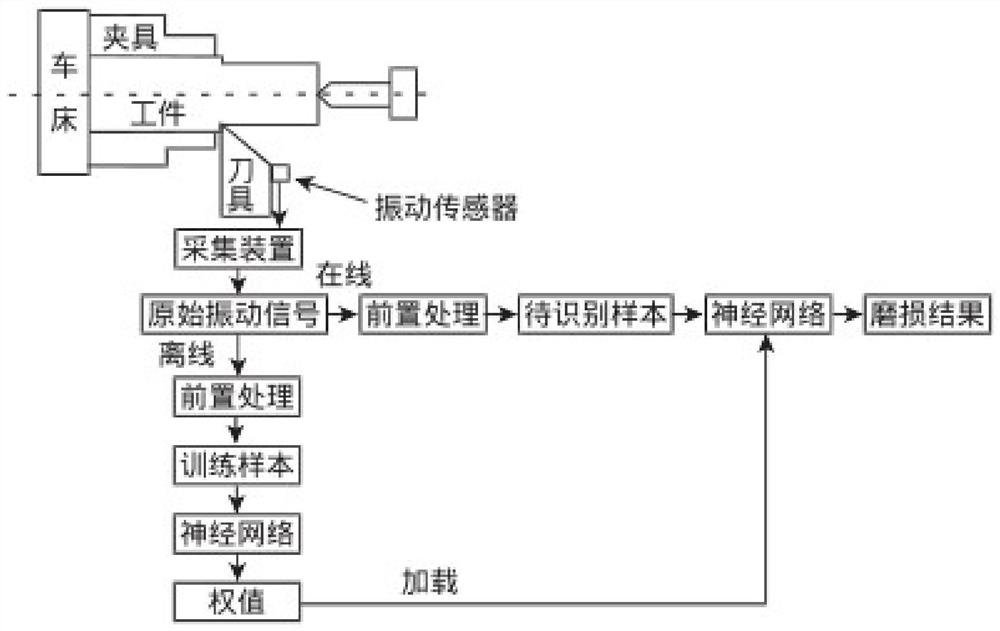

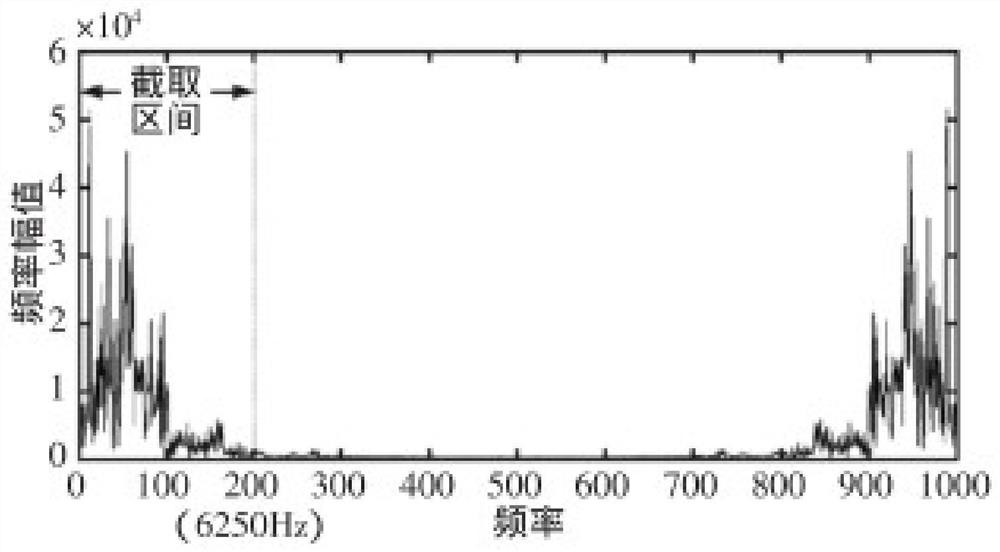

[0026] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 As shown, in this technical solution, such as figure 1 As shown, in the offline mode, the original vibration signal collected in the experiment is pre-processed first to obtain training samples, and then the training samples are input into the neural network for training, and the trained neural network weights are serialized to In the hard disk, avoid the need to repeatedly train the neural network. In the online model mode, the neural network weight file that has been trained and serialized to the hard disk is loaded into the neural network, and then the real-time vibration signal collected by the sensor is pre-processed to obtain the sample to be recognized, and the sample to be recognized is obtained. The samples are input into the neural network, and the predicted value of tool wear can be obtained.

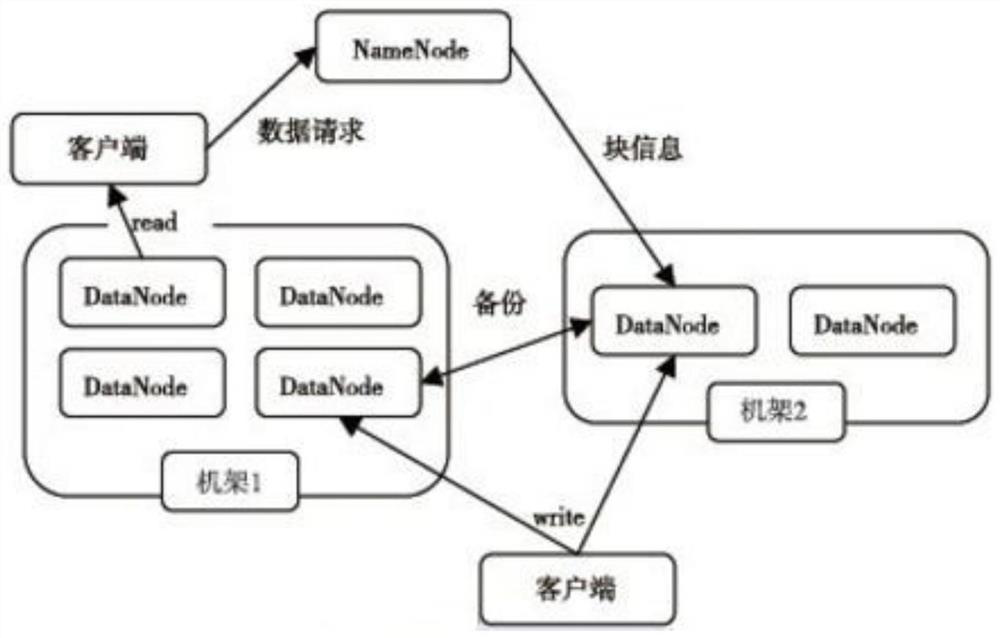

[0027] The data acquisition system consists of a vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com