Method for optimizing thickness of multi-layer heat insulation medium

A technology of medium thickness and optimization method, applied in the field of thermal insulation materials, can solve the problems of inability to optimize the thickness of the medium layer, poor method adaptability, optimization of coating thickness, etc., and achieve the effect of shortening the research and development cycle and reducing the research and development cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

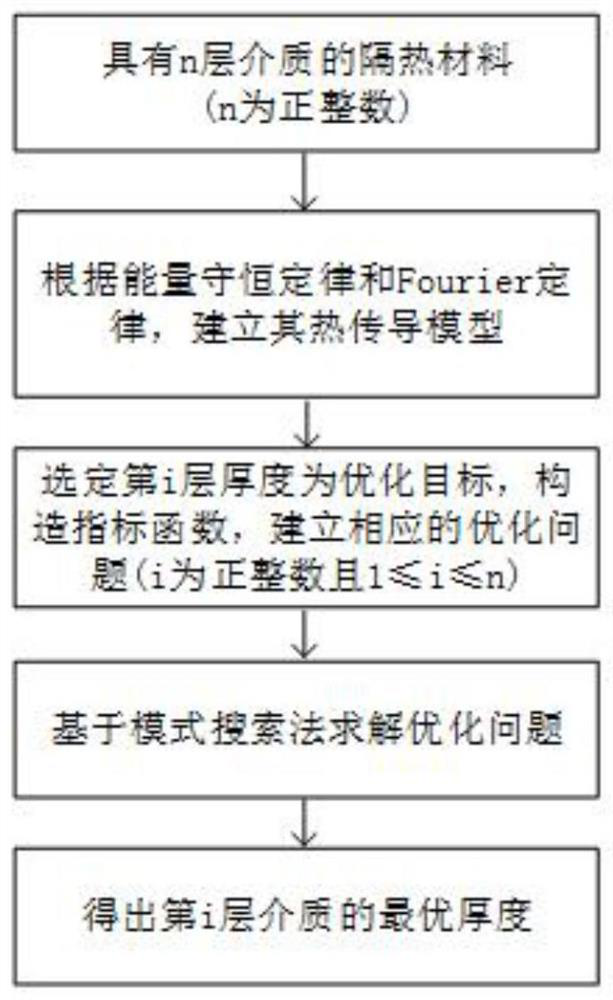

[0028] see figure 1 , a method for optimizing the thickness of a multilayer heat insulating medium, a method for optimizing the thickness of a multilayer heat insulating medium, comprising the following steps:

[0029] Step 1: For a given thermal insulation material with n layers of media, where n is a positive integer, according to the law of energy conservation and Fourier's law, establish its heat conduction model;

[0030] The second step: select the i-th layer thickness as the optimization target, construct the index function, and establish the corresponding optimization problem, i is a positive integer and 1≤i≤n;

[0031] Step 3: Numerically solve the optimization model based on the pattern search method Finally, the optimal thickness of the i-th layer of media can be obtained.

[0032] The existing method can only optimize the thickness of the coating, but cannot optimize the thickness of any medium layer and the method has poor adaptability, and it is impossible to se...

Embodiment 2

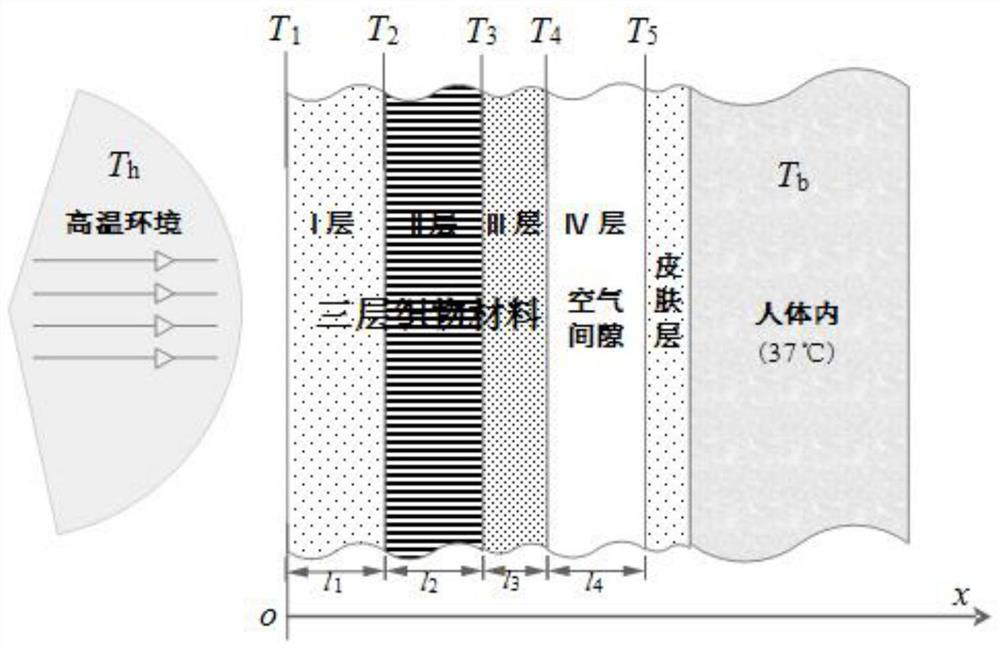

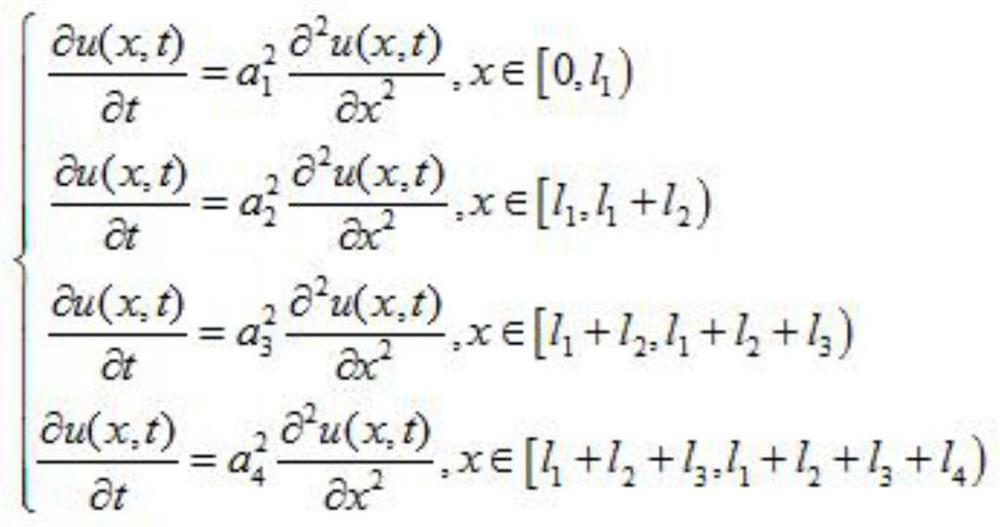

[0036] see figure 2 , image 3 and Figure 4 , when the one-dimensional heat conduction model of multi-layer media is established, at time t, the temperature at any point x in layer I-IV layer media is recorded as u(x,t), where x is the distance from the origin O, according to the uniform The one-dimensional heat conduction equation of the medium can obtain the one-dimensional heat conduction model of the multi-layer medium, such as image 3 As shown, among them, image 3 The initial value and boundary conditions of Equation 1 shown in Figure 4 As shown, among them, k 0 is the convective heat transfer coefficient between the external environment and the surface of layer I, k 5 is the convective heat transfer coefficient between layer IV and the skin surface, is the temperature distribution function at the initial moment.

Embodiment 3

[0038] When constructing an index function and establishing an optimization problem, in order to optimize the thickness of the second layer, customize the index function,

[0039]

[0040] s.t.0.62 <25,(4),(5)

[0041] by t w Indicates the time when the temperature is greater than 44°C, T 5is the skin surface temperature after the experiment. The last two terms are added in because t w and T 5 Neither is an optimization variable. Since it is difficult to constrain it, we adopt the method of penalty function, incorporate it into the indicator term, and convert it into a nonlinear optimization problem with only solution domain constraints. (t w >300) is a judgment statement whose value is:

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com