Method for improving formation liquid loss and application thereof

A liquid volume and gradient change technology, applied in electrochemical generators, secondary battery charging/discharging, electrical components, etc., can solve the problems of increasing liquid loss, affecting battery performance, affecting electrolyte wettability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

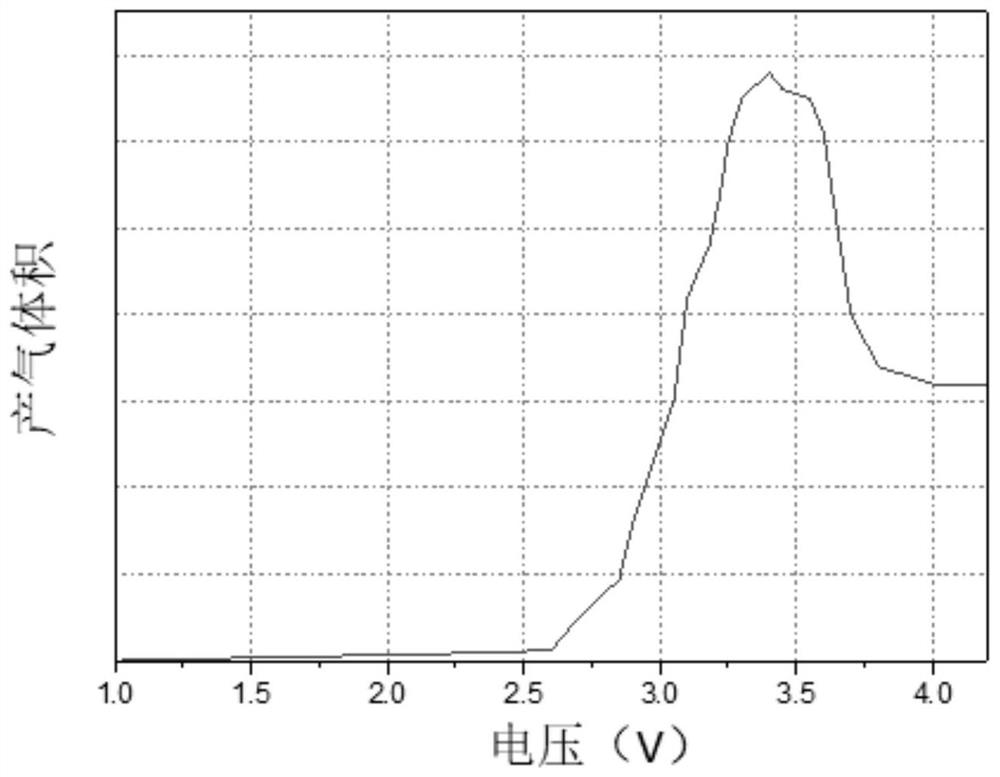

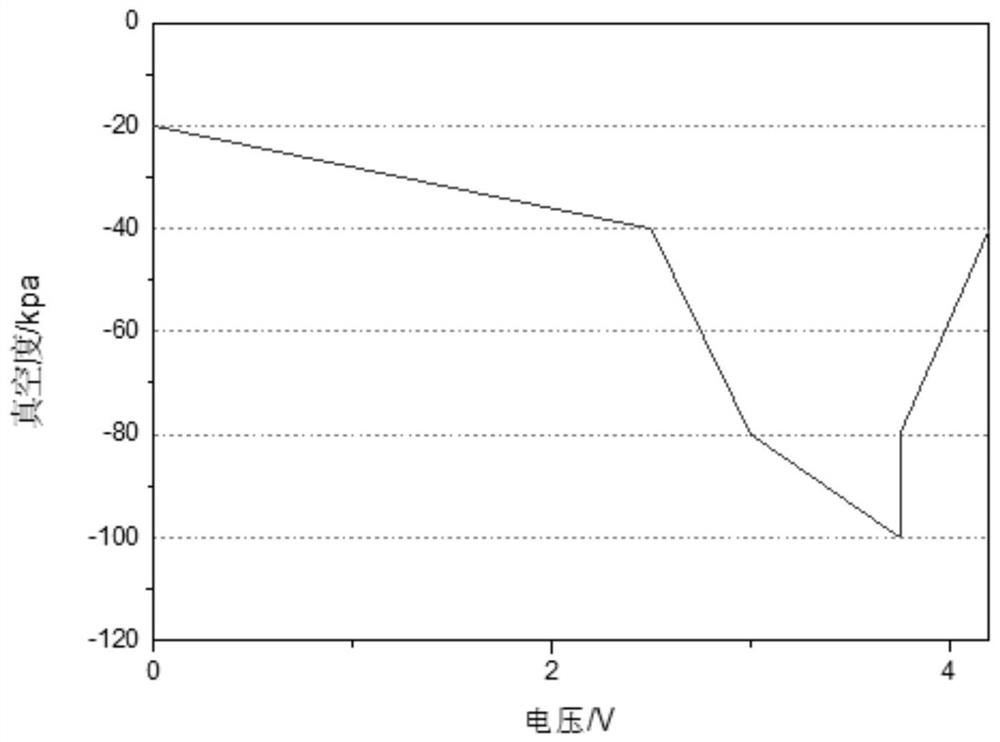

[0049] In this embodiment, the negative pressure formation process adopts the following method, and the process is divided into four stages. The process is as follows: figure 2 shown, including:

[0050] In the first stage, when the voltage is <2.5V, the vacuum degree is adjusted to -20kPa~-40kPa; excluding -40kPa; among them, the growth rate of the vacuum degree with the voltage is -8kPa / V;

[0051] In the second stage, when the voltage is 2.5V ~ 3.0V, excluding 3.0V, the vacuum degree is adjusted to -40kPa ~ -80kPa, excluding -80kPa; among them, the growth rate of vacuum degree with voltage is -80kPa / V;

[0052] In the third stage, when the voltage is 3.0V ~ 3.75V, the vacuum degree is adjusted to -80kPa ~ -100kPa; among them, the growth rate of the vacuum degree with the voltage is -26.7kPa / V;

[0053] In the fourth stage, when the voltage is greater than 3.75V, the vacuum degree is adjusted to -40kPa~-80kPa, excluding -80kPa, and the decrease rate of the vacuum degree wi...

Embodiment 2

[0055] The only difference between this embodiment and Embodiment 1 is that in the first stage, the vacuum degree is constant at -30kPa, in the second stage, the vacuum degree is constant at -60kPa, in the third stage, the vacuum degree is constant at -90kPa, in the fourth stage, the vacuum Degree is constant at-60kPa, and other parameters and conditions are exactly the same as in Example 1.

Embodiment 3

[0057] The only difference between this embodiment and Embodiment 1 is that in the first stage, the vacuum degree is constant at -20kPa, in the second stage, the vacuum degree is constant at -50kPa, in the third stage, the vacuum degree is constant at -100kPa, in the fourth stage, the vacuum Degree is constant at-50kPa, and other parameters and conditions are exactly the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com