Hot-end constant-temperature convective heat exchange type waste heat power generation device

A technology of waste heat power generation and convective heat transfer, which is applied to electromechanical devices, steam engine devices, generators/motors, etc., and can solve the problems of insufficient utilization of waste heat, single power generation form, and uncontrollable hot end temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

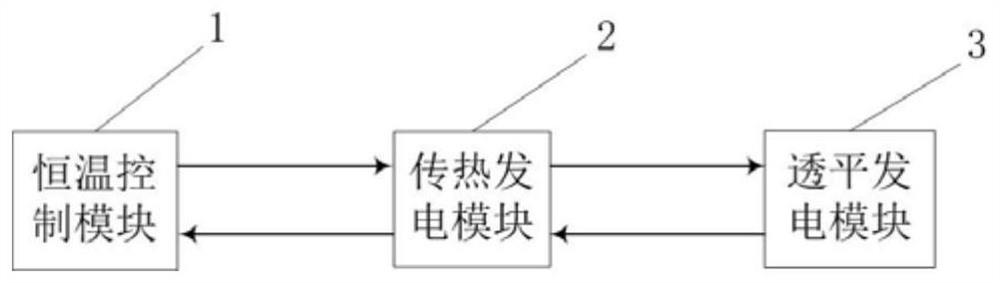

[0096] see attached figure 1 .

[0097] The device consists of a constant temperature control module 1 , a heat transfer power generation module 2 , and a turbine power generation module 3 . The constant temperature control module 1 realizes the control of the temperature of the hot end of the heat transfer power generation module 2; the heat transfer power generation module brings thermal energy to the turbine power generation module 3 while generating electricity; the turbine power generation module converts the heat energy of the heat transfer power generation module into electrical energy.

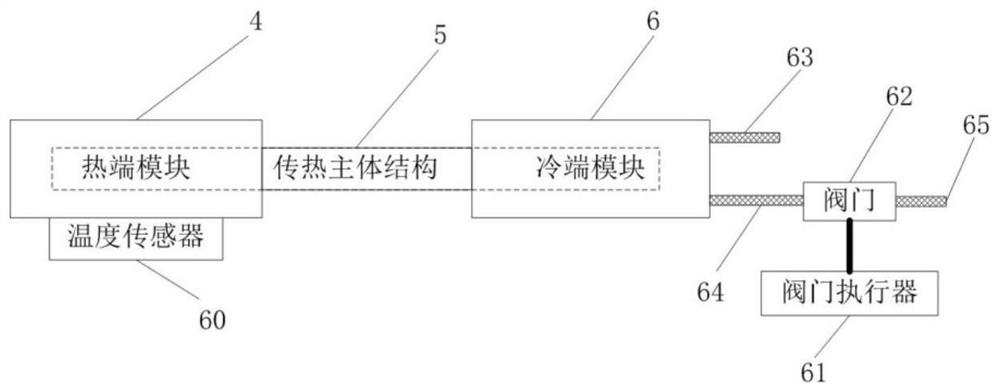

[0098] see attached figure 2 .

[0099] The heat transfer power generation module 2 is composed of a plurality of single-tube heat transfer power generation devices. The single-tube heat transfer power generation device is composed of three parts: a heat transfer main structure 5 , a hot end module 4 and a cold end module 6 . A temperature sensor 60 is installed on the hot end mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com