Hole-digging head structure for seedling planting in forestry and hole digging machine

A technology for digging machines and seedlings, which is applied in the field of digging head structures and digging machines for planting forestry seedlings, and can solve the problems of high cost and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

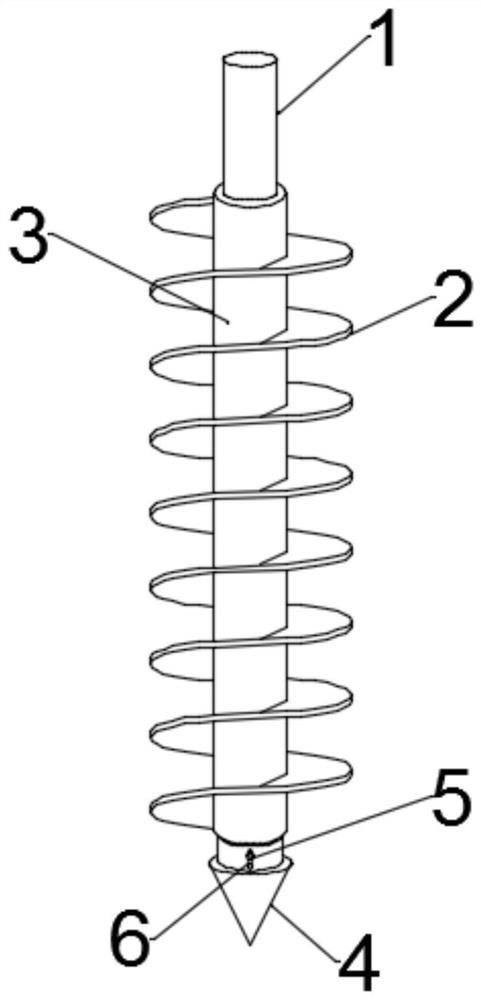

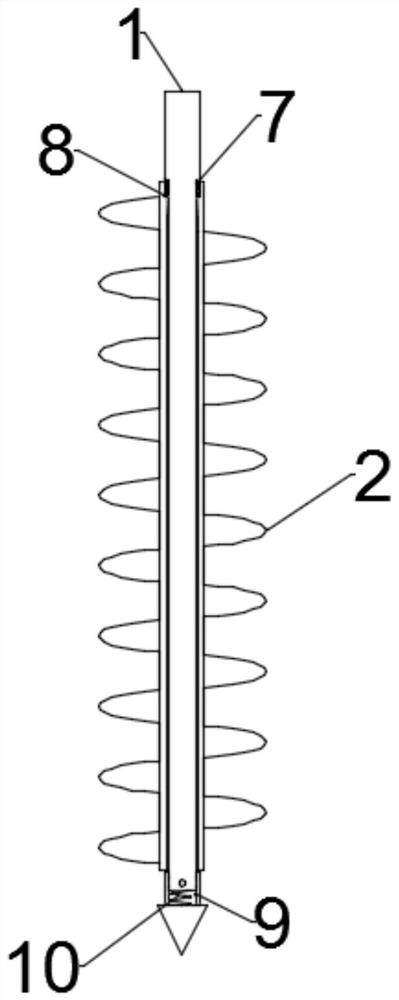

[0025] see Figure 1~2 , in an embodiment of the present invention, a digging head structure for planting forestry seedlings, including a rotating shaft 1 and a helical blade 2; the helical blade 2 is fixed on the outer end of the sleeve 3, and the rotating shaft 1 is inserted into the sleeve 3 and is detachably fixedly connected with the sleeve 3, the lower end of the rotating shaft 1 is detachably equipped with a conical head 4, the upper end of the conical head 4 abuts against the lower end of the sleeve 3, and the split-type digging The structure of the pit head is easy to replace after a part is damaged, saving costs, and the pit head of different digging sizes can be replaced according to the needs, which is convenient to use.

[0026] Specifically, the rotating shaft 1 is provided with an external thread 7 , and the inner wall of the sleeve 3 is provided with an internal thread 8 cooperating with the external thread 7 , so that the sleeve 3 and the rotating shaft 1 are ...

Embodiment 2

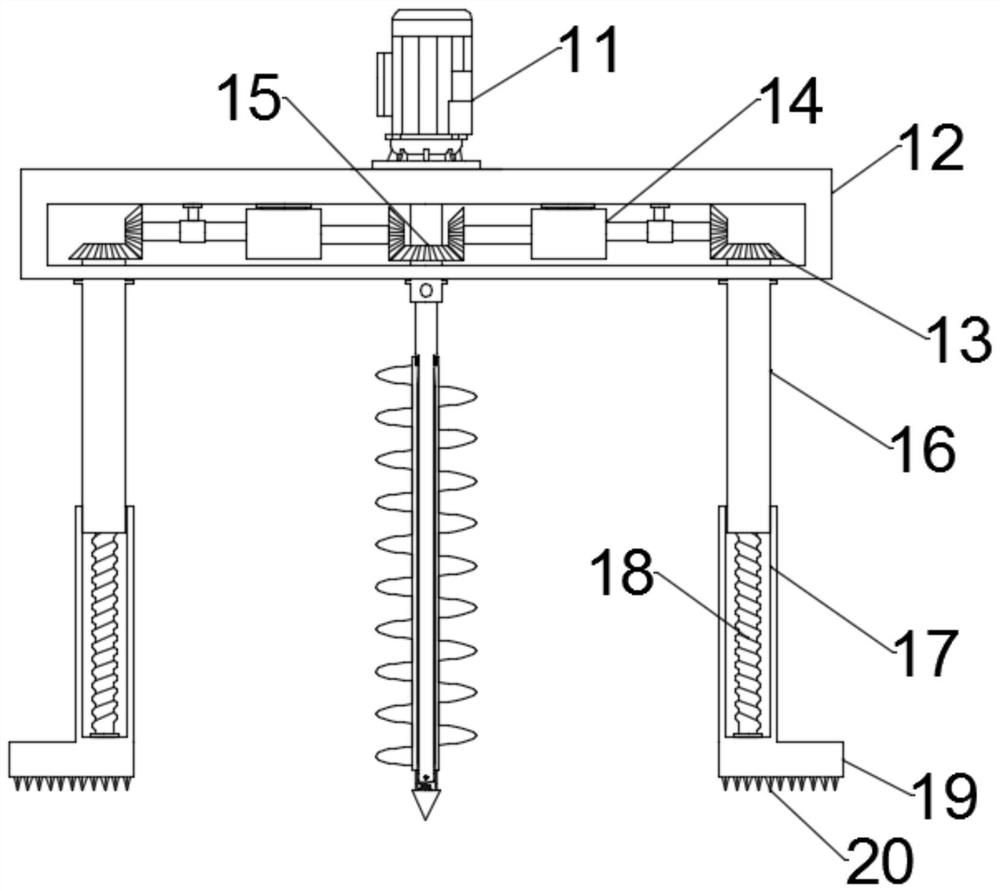

[0029] see image 3 In the implementation of the present invention, on the basis of the above-mentioned embodiments, a digging machine is also proposed, which includes a digging machine body, and also includes a digging head structure for planting forestry seedlings as described in the above-mentioned embodiments.

[0030] Specifically, the digging machine body includes a motor 11, a support plate 12 and a telescopic outrigger assembly. There are at least three sets of telescopic outrigger assemblies, and the telescopic outrigger assembly is installed on the lower end of the support plate 12 in a circumferential direction. The motor 11 is installed on the upper end of the support plate 12 and the output shaft of the motor 11 runs through the support plate 12 and is detachably connected with the digging head structure for planting forestry seedlings. The telescopic outrigger assembly telescopic transmission mechanism, the motor 11 drives the digging head structure for planting ...

Embodiment 3

[0036] see image 3 In the implementation of the present invention, on the basis of the above-mentioned embodiments, a digging machine is also proposed, which includes a digging machine body, and also includes a digging head structure for planting forestry seedlings as described in the above-mentioned embodiments.

[0037] Specifically, the digging machine body includes a motor 11, a support plate 12 and a telescopic outrigger assembly. There are at least three sets of telescopic outrigger assemblies, and the telescopic outrigger assembly is installed on the lower end of the support plate 12 in a circumferential direction. The motor 11 is installed on the upper end of the support plate 12 and the output shaft of the motor 11 runs through the support plate 12 and is detachably connected with the digging head structure for planting forestry seedlings. The telescopic outrigger assembly telescopic transmission mechanism, the motor 11 drives the digging head structure for planting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com